By Taha KhanReviewed by Lexie CornerJun 18 2024

By Taha KhanReviewed by Lexie CornerJun 18 2024Thermal runaway is a hazardous phenomenon where the heat generated by a process exceeds its dissipation rate, leading to uncontrollable acceleration and rising temperatures. This issue is particularly critical in batteries and electronics, such as processors and graphic cards, where overheating can cause components to melt or ignite, leading to catastrophic failures.1, 2

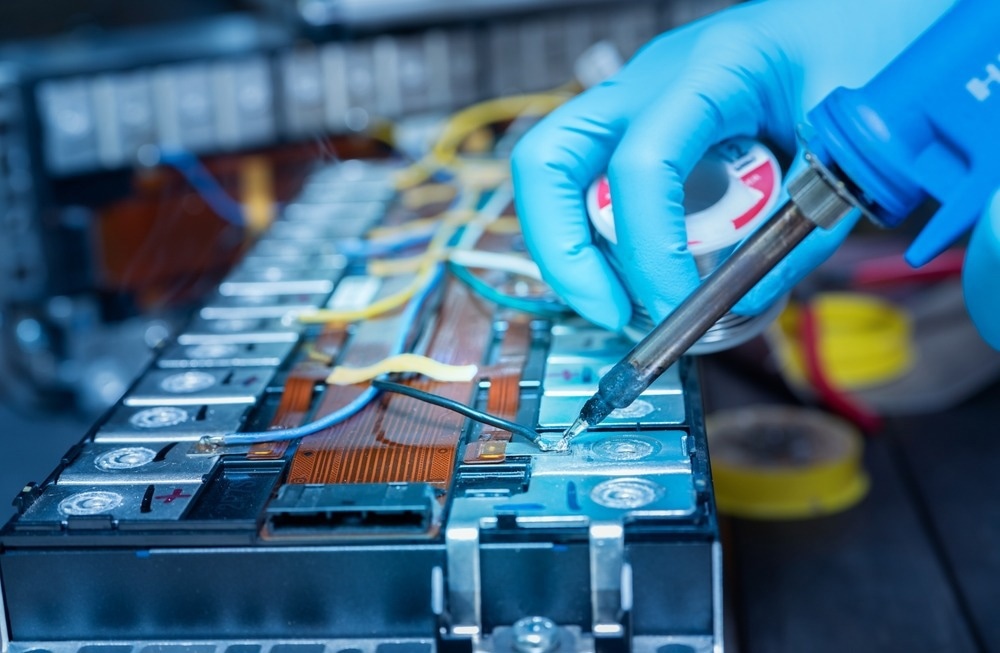

Image Credit: Fahroni/Shutterstock.com

Causes of Thermal Runaway

Thermal runaway can result from various factors, including chemical reactions, battery overcharging, environmental conditions, and operational practices. Exothermic reactions, for example, can accelerate as temperatures rise, increasing heat production.

Insufficient cooling and contaminants can exacerbate this situation by allowing heat to accumulate and catalyzing unwanted reactions, potentially leading to explosions.2, 3

In batteries, thermal runaway can be triggered by electrolyte breakdown, short circuits from physical damage, poor thermal management, or manufacturing defects, leading to hotspots and failures.1, 4

Environmental factors like high ambient temperatures and poor ventilation, combined with operational conditions such as overcharging or overloading, can also induce thermal runaway. For example, in electronic devices, insufficient cooling or blocked ventilation can cause components to overheat, resulting in the melting of circuits.2

Thermal Runaway without Short-Circuiting

A 2018 study revealed that thermal runaway in lithium-ion batteries can occur without internal short circuits, driven instead by chemical interactions. During thermal runaway, the cathode undergoes a phase transition, releasing oxygen that reacts with the lithiated anode, generating substantial heat (up to 274.2°C).5

Researchers used liquid nitrogen to freeze batteries mid-runaway for detailed analysis, confirming the role of chemical interactions in thermal runaway. These insights emphasize the importance of system-level safety design in automotive and solid-state lithium-ion batteries.5

Consequences of Thermal Runaway

The consequences of thermal runaway can be severe, including melting, warping, or permanent damage to electronic components, batteries, and entire systems, resulting in significant financial losses and data loss.

Additionally, uncontrolled chemical reactions can release toxic fumes or cause explosions, posing health and safety risks to personnel and property. 2, 3

Mitigation and Prevention Strategies

To mitigate and prevent thermal runaway, effective design and engineering controls are crucial. This includes using materials that withstand high temperatures, ensuring adequate cooling and ventilation, and incorporating thermal management features such as thermal barriers and heat sinks. For example, incorporating proper thermal barriers and heat sinks in the design of electronic devices can help dissipate heat efficiently and prevent overheating.2, 4

Robust monitoring systems for early detection of potential thermal runaway, including sensors for temperature, pressure, and other critical parameters, are essential. Emergency response protocols, such as automatic shutdown systems and fire suppression mechanisms, can further mitigate the impact.6

Customizable Solutions for Battery Pack Thermal Runaway Propagation Protection

Mitigating Thermal Runaway in Batch Reactors

In a 2016 study, researchers developed a comprehensive framework for preventing and mitigating thermal runaway in batch reactors used for exothermic reactions. They identified key parameters that influence thermal runaway, such as cooling system failures, critical temperature thresholds, and rates of temperature change over time.7

Using the synthesis of peracetic acid as a case study, the researchers determined critical values and employed Monte Carlo simulations to estimate the risk of thermal runaway under specific conditions. This approach helps predict potential reactor failures and enhances safety by enabling better design and risk management strategies to prevent thermal runaway and subsequent accidents.7

Industry Examples

Various industries have implemented protocols to address thermal runaway. For instance, EV batteries incorporate safety features like thermal fuses (which cut off the battery's connection if temperatures become excessive), pressure relief valves to vent excess gas buildup, and temperature monitoring systems that alert drivers of potential thermal runaway.4, 8

Data centers use air conditioning units, water cooling systems, and strategic airflow management to maintain optimal temperatures. Many electronic devices, such as laptops and smartphones, also have built-in overheat protection features that can automatically throttle performance, shut down the device, or display warning messages when temperatures reach critical levels.

Future Outlook

Researchers are developing high-temperature-resistant materials with improved thermal interfaces to enhance heat management. Innovations in cooling systems and battery technology, such as lithium-ion batteries, can significantly reduce the risk of thermal runaway.

For instance, in a 2017 study, researchers developed an innovative minichannel cooling system to enhance thermal management in lithium-ion battery modules used in electric vehicles and hybrid electric vehicles (HEVs).8

This system features aluminum multi-port extrusions that allow coolant to flow through, efficiently absorbing heat from the batteries. Nail penetration tests, simulating internal short circuits, demonstrated that while the minichannel cooling system could not prevent thermal runaway in an individual cell, it effectively stopped thermal runaway propagation to adjacent cells.

The system successfully mitigated the risk of thermal fratricide by controlling each cell's coolant flow rate independently, enhancing safety in electric and hybrid vehicle battery modules.8

Overall, the development of more sophisticated thermal management systems and control algorithms promises further improvements in preventing future runaway situations.

More from AZoM: Harnessing AI and Machine Learning for Advanced Materials Testing

References and Further Reading

- Galushkin, NE., Yazvinskaya, NN., Galushkin, DN. (2018). Mechanism of thermal runaway in lithium-ion cells. Journal of The Electrochemical Society. doi.org/10.1149/2.0611807jes

- Saada, R., Patel, D., Saha, B. (2015). Causes and consequences of thermal runaway incidents—will they ever be avoided?. Process safety and environmental protection. doi.org/10.1016/j.psep.2015.02.005

- Wang, Q., Ping, P., Zhao, X., Chu, G., Sun, J., Chen, C. (2012). Thermal runaway caused fire and explosion of lithium ion battery. Journal of power sources. doi.org/10.1016/j.jpowsour.2012.02.038

- Feng, X., Ren, D., He, X., Ouyang, M. (2020). Mitigating thermal runaway of lithium-ion batteries. Joule. doi.org/10.1016/j.joule.2020.02.010

- Liu, X., et al. (2018). Thermal runaway of lithium-ion batteries without internal short circuit. Joule. doi.org/10.1016/j.joule.2018.06.015

- Koch, S., Birke, KP., Kuhn, R. (2018). Fast thermal runaway detection for lithium-ion cells in large scale traction batteries. Batteries. doi.org/10.3390/batteries4020016

- Ni, L., Mebarki, A., Jiang, J., Zhang, M., Pensee, V., Dou, Z. (2016). Thermal risk in batch reactors: Theoretical framework for runaway and accident. Journal of loss prevention in the process industries. doi.org/10.1016/j.jlp.2016.04.004

- Xu, J., Lan, C., Qiao, Y., Ma, Y. (2017). Prevent thermal runaway of lithium-ion batteries with minichannel cooling. Applied Thermal Engineering. doi.org/10.1016/j.applthermaleng.2016.08.151

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.