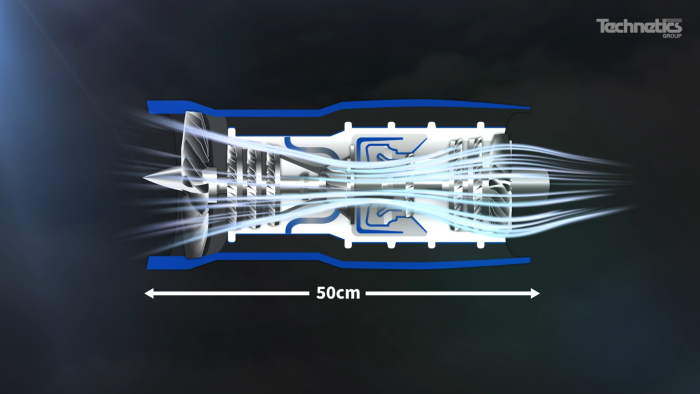

Optimizing the airflow within turbine engines is critical in reaching peak efficiency and performance. Airflow management guarantees that the engine operates within the design parameters, maximizing fuel efficiency and power output with minimal emissions. Loss in airflow caused by turbulence and friction and the natural habit of air moving toward low-pressure areas are two of the key reasons for a loss in efficiency in compressors within a turbine engine. This loss is more substantial in smaller turbines than in larger varieties because of their compact size.

Image Credit: Technetics Group

Advanced clearance control materials, like FELTMETAL™ abradable seals, are essential in minimizing air leakage. This results in better overall engine performance, sustainability, and reliability which are crucial for maintaining the strict demands of contemporary aviation and power generation industries.

Every millimeter of space is crucial in the search for unbeatable performance in compact turbine engines and compressors. Engineers are faced with an abundance of challenges when choosing effective sealing solutions that are able to operate with efficiency in greatly confined spaces.

Technetics understands these specific demands. Its FELTMETAL™ Abradable Seals are uniquely designed for the requirements of high-performance, small-scale turbines, offering unparalleled efficiency and reliability.

The Challenges of Compact Turbine Engines

The microturbine market is expected to increase as attention to reducing greenhouse emissions increases in the next few years. However, their reduced size makes for several engineering challenges:

- Space Limitations: Compact engines offer limited space for components, making implementing traditional sealing solutions that do not compromise performance more difficult.

- Temperature and Heat Dissipation: These engines typically operate at high temperatures, which requires materials that can withstand extreme conditions and dissipate heat.

- Tip Clearance: Achieving tight clearance control is crucial for maintaining engine efficiency and performance.

This information has been sourced, reviewed and adapted from materials provided by Technetics Group.

For more information on this source, please visit Technetics Group.