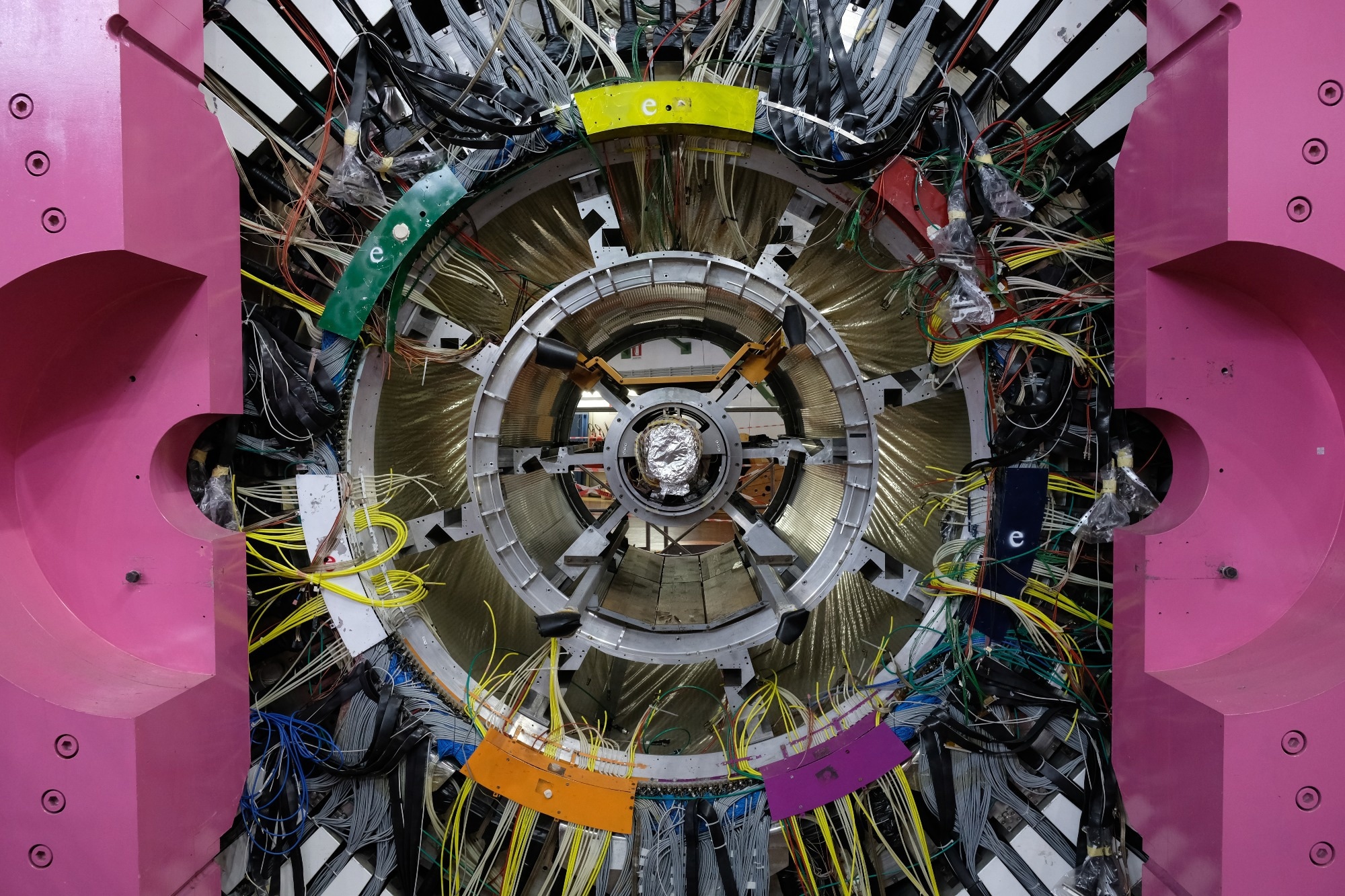

The Advanced Light Source (ALS) research facility at the Lawrence Berkley National Laboratory (Berkley Lab) advances science through synchrotron light source abilities.

As a part of an ALS upgrade initiative, Berkley Lab required a sealing solution for its accumulator ring: an ultra-high vacuum (UHV) sealing solution suitable for a synchrotron with a seal at the beam position monitor (BPM) housing.

Image Credit: MauriozioS/Shutterstock.com

The provisions for this application included a leak rate of 1×10-9 cc/sec He atm and operating and bake-out temperatures of 25 ºC and 180 ºC, respectively, for one hour at initiation. Furthermore, the lab required four seals for each of the 72 seal assemblies, making a total of 288 seals for the application's initial startup.

Due to the strong relationship between Berkley Lab and Technetics Group, Technetics’ contribution to the ALS “Kicker Box” assembly, and its proficiency and industry experience, Technetics was employed for this application. The company received the accumulator ring BPM application from Berkley Lab after being invited to conduct a presentation on metal seals.

The HELICOFLEX® DELTA seal was chosen as an ideal solution for this application. This seal integrates two small ridges, or deltas, on the seal’s surface.

The high contact stress in the seal track makes this particular choice perfect for UHV applications that necessitate ultra-low helium leak rates.

After receiving the prototype order and completing pump-down testing, Technetics was awarded additional prototype orders, with the expectation of further MRO demands every other year.

This information has been sourced, reviewed and adapted from materials provided by Technetics Group.

For more information on this source, please visit Technetics Group.