Traditional Conductive AFM (C-AFM) seems to be moving aside to make space for a more advanced technology: ResiScope III – a new module for the Nano-Observer II AFM system.

This move represents a major development for the atomic force microscopy (AFM) community and a significant leap forward in electrical characterization capabilities at the nanoscale.

Breaking New Ground in Measurement Range

The most notable advantage of ResiScope™III over conventional C-AFM lies in its unparalleled measurement range.

Since its inception, C-AFM has been limited in scope, but ResiScope™III's single module can measure both resistance and current within 10 orders of magnitude (100 ohms-1 GOhm and 50 fA-1 mA respectively).

The ResiScope™III is a more versatile and efficient solution for researchers. Its extensive range eliminates the need to frequently change experimental setup or adjust amplifier gains.

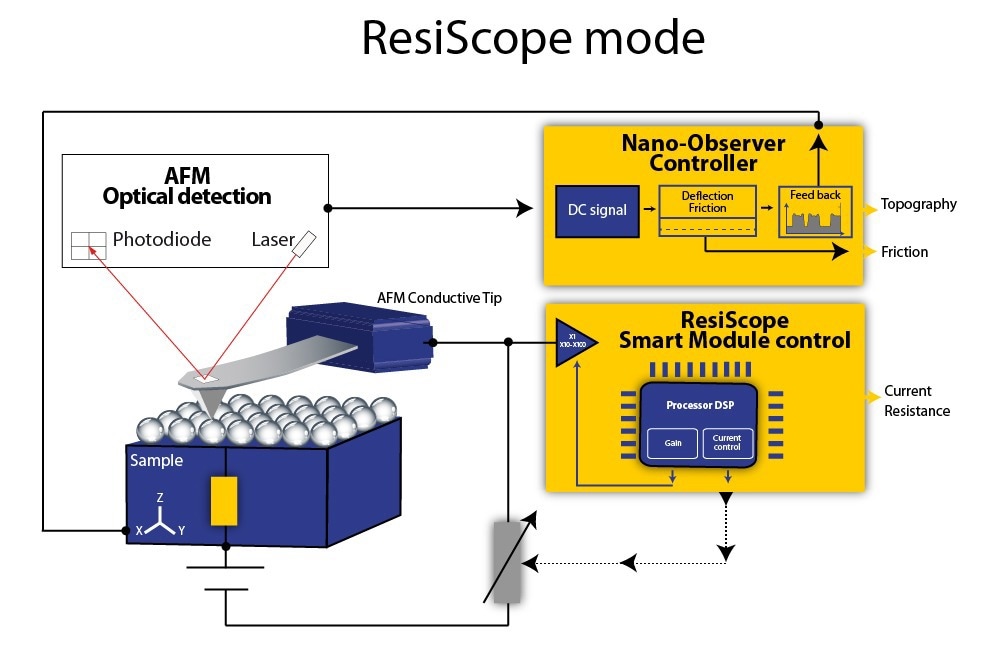

Figure 1. Schematics of ResiScopeTM III . Image Credit: CSInstruments

The fundamentals of ResiScope™ III are clearly illustrated by its working principle schematics (Figure 1). The sample is biased and the current flowing through the tip is then processed in the ResiScope™ III module. In essence, this fast-response electronics selects the adequate amplifier gain (only linear amplifiers are used) for the level of current on each pixel of the image, which implies response times of just a few microseconds. Additionally, it provides a protective resistance (according to the sample resistivity on each pixel of the image) to limit the current and minimize undesired side effects (like local oxidation).

Transforming Research Workflow with Real-time Capabilities

The ResiScope™ III's most distinguishing feature is its processor-driven auto-ranging capability. This powerful technology allows the system to adjust measurement ranges in real-time, effortlessly facilitating regular AFM scan speeds of 1-3 lines per second with 512 pixels per line.

This real-time current limit removes the risk of sample damage and ensures measurement accuracy across diverse sample conductivities with no need for manual intervention from researchers.

Superior Visualization and Artifact Elimination

Conventional C-AFM has faced historic challenges in terms of visualization limitations and artifacts from tip-sample interactions or surface charging. These limitations affect the following types of samples:

- Conductive and insulating domains within the same area/image. Typically, C-AFM has a very short range of 3-4 orders of magnitude (ResiScope™ III provides 10!), which implies that only conductive or insulating domains can be measured at a time. A typical situation is to have an image with contrast between insulating and conductive areas; however, the conductive areas have, in fact, a saturated current.

- Insulating samples: surface charge effects that appear as a slope as the tip is scanning the surface.

- In the case of highly conductive samples (> 1 µA), C-AFM is simply not capable of handling such high currents (conductive coating of the tip melts, damage to the sample, etc.). Also, another typical effect on these types of samples is a capacitive discharge effect (i.e., the amplifier response time is very slow for high current values).

The ResiScope™ III has been designed to directly address the aforementioned limitations, offering superior imaging of conductive areas and also avoiding the artifacts that make conductive measurements difficult to handle.

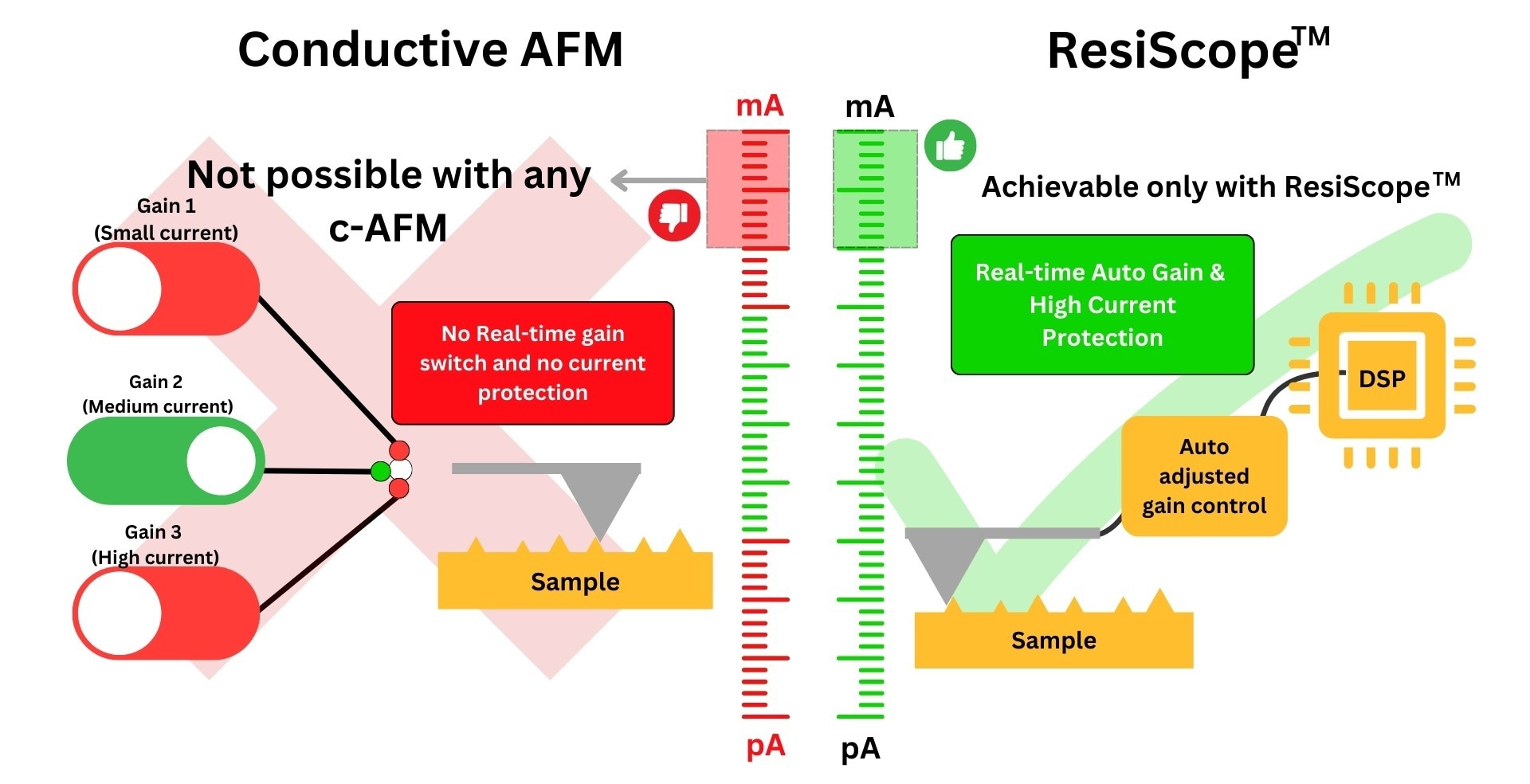

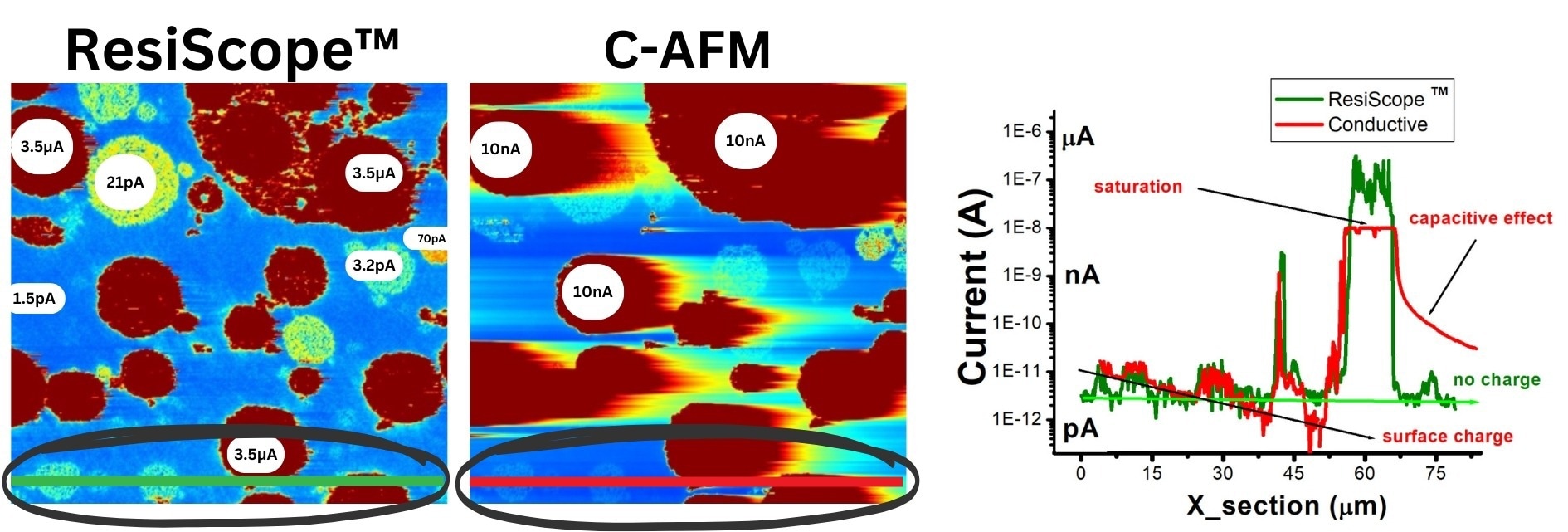

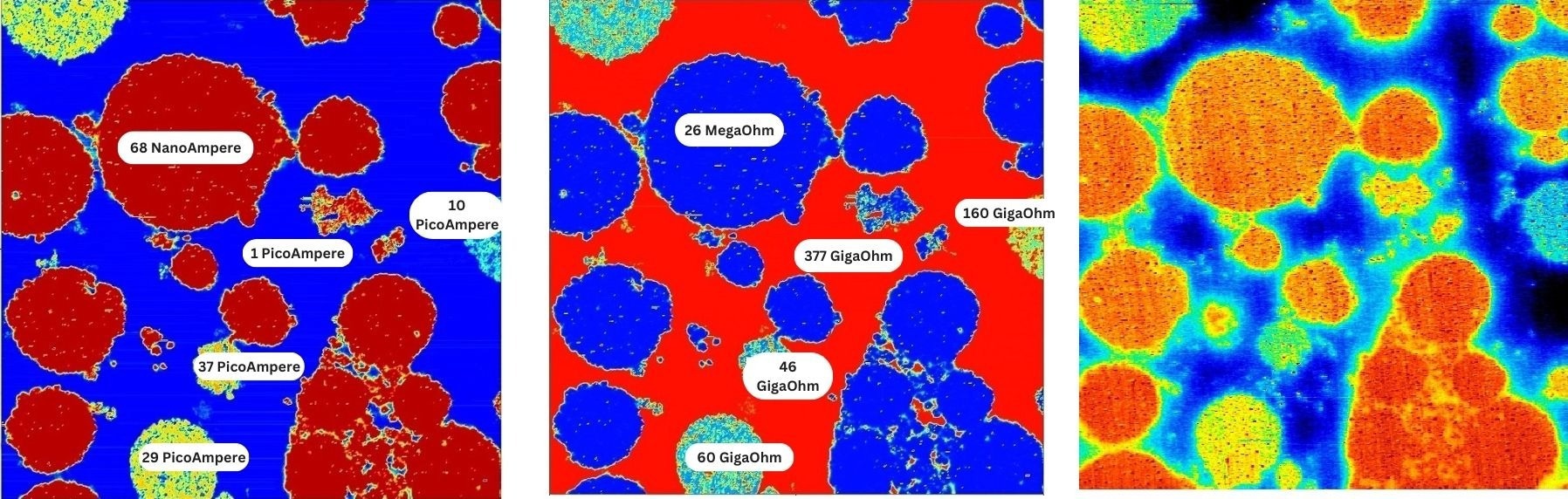

Figure 2 highlights how ResiScope™ III overcomes the limitations of C-AFM, most notably in terms of its ability to measure wide ranges of conductivity without compromising sample integrity or measurement accuracy.

Figure 2. Comparison between ResiScope™ III and c-AFM.Image. Credit: CSInstruments

The sample measured in Fig. 2 is a solid-state battery showing round conductive and insulating domains surrounded by an insulating matrix. Fig. 2 (left) corresponds to the ResiScope™ III current image where domains ranging from a few pA up to 100 nA can be seen. Fig. 2 (middle) shows the corresponding measurement with a medium-gain C-AFM setup of the same area. This image shows that insulating domains are measured; however, conductive domains show both saturation of the signal (10 nA maximum current for the selected C-AFM setup) and capacitive discharge effects. Fig. 2 (right) shows a graph with cross-sections on the depicted dashed lines for clarity. The surface charge effect is clearly visible (negative slope from left to right).

Applications Spanning Various Fields

The versatility and adaptability of the ResiScope™ III lend themselves to use in a diverse array of applications, including:

- Semiconductor analysis, such as defect analysis and doping profiling

- Battery and solar cell research, where the instrument enables vital insight into charge transport mechanisms

- Characterization of 2D materials, including comprehensive layer-dependent conductivity measurements

- Polymer and composite studies, most notably using the instrument's Soft ResiScope™ mode

- Thin film characterization, including transparent conductive oxide analysis

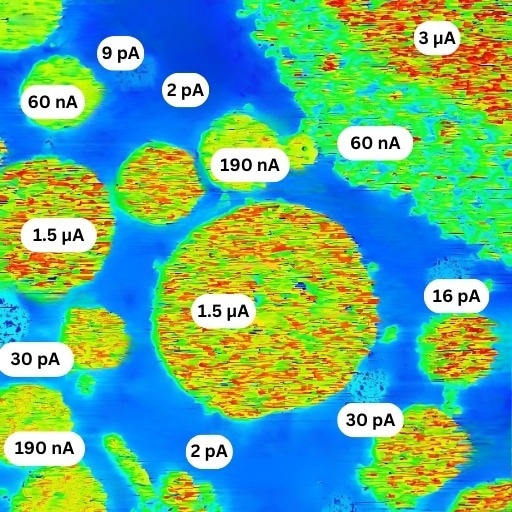

Fig. 3, showing a polymer battery sample analysis, represents a noteworthy example of ResiScope™ III's capabilities. In the example below, a 50×50 micron scan showed intricate current/resistance distribution details, illustrating the system's capacity to capture fine electrical variations across the sample surface.

Figure 3. ResiScope™ III current/resistance map of a polymer battery sample (50x50 micron scan size). Image Credit: CSInstruments

All-in-One AFM Configuration: Simplified Mode Switching with ResiScope™

ResiScope™ III setup is compatible with various AFM modes, including oscillating mode, contact mode, and force spectroscopy. This means the user can use the same setup for ResiScope™ and change to any other mode simply by clicking in the software.

It is also compatible with advanced techniques such as MFM/EFM and HD-KFM, affording researchers a wide-ranging and versatile suite of analytical capabilities. Furthermore, ResiScope™ III can also be combined with Soft Intermittent Contact mode (Soft IC), thus avoiding the inherent friction during the scan in traditional contact mode. This helps make it easier to measure soft samples and preserve the durability of the conductive tip.

Figure 4 shows an example of measurement with Soft ResiScope™ III and HD-KFM of the same area of a polymer battery. As mentioned above, the user can change from one mode to another simply by clicking in the software (no need to change setup or cantilever holder). Additionally, as compared to Figure 3, it can be appreciated that Soft ResiScope™ III provides a better-defined current image compared to standard ResiScope™ III.

Fig. 4. Soft ResiScope™ and HD-KFM surface potential images of the same area on the polymer battery sample (50×50 micron scan size). Image Credit: CSInstruments

The Future

Nanoscale electrical characterization is expected to become increasingly central to materials research and development. ResiScope™ III is poised to become the new standard as this field advances.

Its powerful combination of high sensitivity, wide measurement range, and versatility makes it an essential tool for researchers in nanomaterial development and device optimization.

The transition from conventional C-AFM to ResiScope™ technology marks an important milestone in AFM instrumentation, potentially fast-tracking the development of next-generation devices and materials across various industries.

Acknowledgments

Produced from materials originally authored by CSInstruments.

This information has been sourced, reviewed and adapted from materials provided by CSInstruments.

For more information on this source, please visit CSInstruments.