|

CeramTec high performance ceramic materials are the solution to many demanding applications in the automotive industry.

Engine Management

- Valve discs for high-pressure injection systems

- Components for electric fuel pumps

- Rotating seal rings for coolant-water pumps

- Bushings

- Components for pressure transducers

- Preforms for cylinder liners

- Heating elements, e.g. in oxygen sensors

- Modules for thermal and electric insulation

- Heat sinks

- Piezoelectric knock sensors

- Piezoceramics for liquid level sensors

- Films as a basis for lambda probes

- Components for control electronics

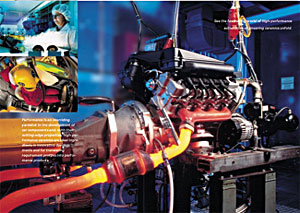

Figure 1. Ceramics for use in engines

Car Lighting

- Contact systems for halogen light

- Switching spark gaps for xenon light

- Components and modules for thermal and electric insulation

Automotive Electronics

Electronic Engine Management

- Films for microhybrid circuitry (LTCC)

- Substrates as a basis for electronic circuitry

- Substrates as sensor elements for mass air flow sensors

Passenger Protection Systems

- Substrates for air bag control

- Acceleration sensors

- Piezoelectric back-up sensors

Transmission and Suspension Systems

- Films for microhybrid circuitry (LTCC) used on ABS/ASR and ESP assemblies

- Substrates as a basis for ABS/ASR and ESP assemblies

- Substrates as a basis for controlling infinitely-variable automatic transmissions

- Substrates for monolithic pressure sensors

- Resistor carriers for all electronic assemblies

- Piezoceramics for Gyro sensors

- Piezoceramic actuators for transmission hydraulics

- Piezoceramic actuators for hydraulic valve controls on ABS, ASR and ESP

- Piezoceramic actuators for vibration and noise suppression and for chassis/suspension control

Metal Removal

When it comes to metal removal, pace and precision are the decisive factors. SPK cutting materials and tools from CeramTec offer decisive advantages in fierce competition - for turning, milling, and drilling. Due to their excellent properties, innovative cutting materials for high-performance metal removal and a custom-tailored tool program assure economical and efficient manufacture with high reliability. Complex and expensive hard machining is a thing of the past. And so are cooling agents. Many OEMs and their vendors have already taken this turn for the better.

Beating the Heat: High-Performance Ceramics for the Engine

Engine components are exposed to the highest stress and many other factors through temperature fluctuations, splashing water and shocks. These are perfect preconditions for materials and systems technology offering the highest performance. Ceramic materials can be very lightweight and extremely heat, wear and corrosion resistant. With utmost reliability, they perform critical chores where conventional materials fail. In particular, MMC composites as well as structural ceramics offer today's design engineers new perspectives in lightweight engine manufacture.

High-Performance Ceramics: More Light, More Sight, More Safety

Seeing and being seen is an essential aspect of motoring safety and car headlamps are the subject of innovative development work. Today's systems use halogen has discharge lamps comprising parts from high-performance ceramics engineered for precise, long life and hence safe motoring.

Parts for Gas Discharge Lamps

Bluish-white xenon light can be seen shining from more and more car headlamps and leads to a significant improvement in the field of vision and hence greater road safety.

Switching spark gaps from metallized alumina ceramics generate a short-time pulse for sparking the gas discharge lamps. In performing this role, the ceramic system parts ensure excellent electric insulation, with the silicate ceramics specially developed for this application featuring a reflection-free surface.

Contact Systems for Halogen Light

Extreme temperatures under UV loads require the use of ceramic bases and mountings on today's advanced halogen lamps, another area in which our high-performance ceramics deliver durability and cost efficiency.

|