Abrasive grains are any hard, sharp material that can be used to wear away another material when one or the other is moved in pressurized contact. Abrasive grains are produced from a variety of different materials; Alumina (Al2O3), Silicon Carbide (SiC), SG, CBN, Diamond, etc.

It is the hardness and sharp particle shape of these materials that makes them abrasive. The Grit number is the designation of abrasive grain size, reflecting the number of the smallest openings per linear inch in the screen through which the grain will pass, these can range from No.4 to No. 2500. The particle size (Dv50) can vary from several millimeters to less than 2 microns.

Applications of Abrasives

These materials are used in a variety of different applications when incorporated into a suitable matrix; for example as sandpaper, in grinding wheels, for lapping, for wire-sawing, as honing sticks, for sandblasting etc.

Different applications may demand different grain shapes and this has a significant influence on the abrasives performance.

Manufacture of Abrasive Grains

The main grain crushing techniques are primarily impact crushing, crushing by pressure, crushing by abrasion or a combination of all three.

Manufacturers of abrasive grains can influence the grain shape by employing different crushing methods, but controlling the shape has so far been more difficult.

Depending on customer preferences, and end use, grain shape requirements differ widely.

Traditional Quality Control Parameters

The International standards for manufacturing of abrasive grains describe methods for measuring bulk density.

Bulk density gives an indication of grain shape, but several other product characteristics also influence the bulk density, i.e. Particle Size Distribution, flow ability and surface condition.

Abrasive Particle Shape Characterization

Recently a new instrument (Sysmex FPIA- 3000) for the rapid particle size and shape characterization has become available. Measurements from this instrument have enabled a more precise way of characterizing different grain shapes, and differences in grain shape between otherwise similar products.

How the Sysmex FPIA-3000 Particle Shape Analyser Works

The Sysmex FPIA- 3000 uses sheath flow and patented high speed image analysis for rapid particle size and shape characterization, typically generating data within 2.5 minutes. Traditionally shape characterization was performed using conventional microscopy with image analysis and this can take up to 2-3 hours per sample.

Particle Circularity

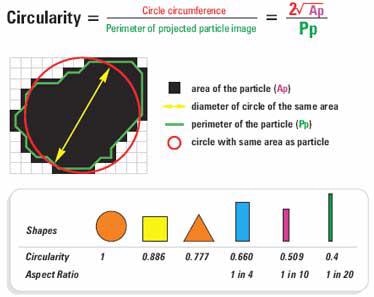

One of the primary shape indexes generated by the Sysmex FPIA- 3000 is circularity. This is defined as the ratio between the circumference of a circle of equivalent area to the particle and the perimeter of the particle itself. The more spherical the particle, the closer its circularity is to 1. The more elongated the particle, the lower its circularity. This concept is illustrated in Figure 1.

Figure 1. Quantifying particle shape – the calculation of circularity.

Measurement Data

To illustrate this concept the circularity is shown for two different grain types in Table 1. The two grain types are:

- Sharp shaped grains and

- Compact shaped grains.

Table 1. Circularity for two different grain types.

| Mean Circularity |

| Sharp shaped grains |

0.886 |

26.6 |

| Compact shaped grains |

0.927 |

9.3 |

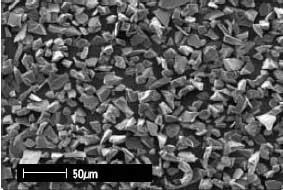

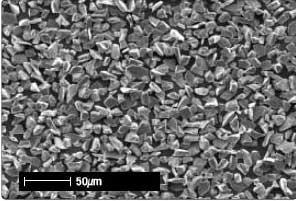

Scanning electron microscope pictures of these are shown in Figures 2 and 3.

Figure 2. SEM image of sharp shaped grains.

Figure 3. SEM image of compact shaped grains.

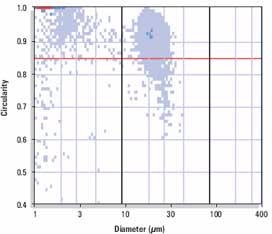

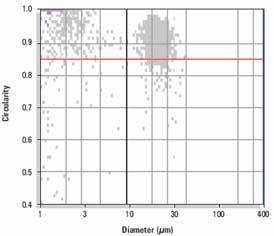

Particle Size/Circularity Scattergrams

For simple visual data interpretation this is clearly shown in the size/circularity scattergrams in the FPIA-3000 software (Figures 4 and 5).

Figure 4. Scattergram of sharp shaped grains.

Figure 5. Scattergram of compact shaped grains.

Conclusion

Rapid particle shape characterization has been shown to provide far more information than current QC tests, enabling the rapid identification of out of specification material. A simple additional test has been able to identify previously unknown manufacturing variations.

Implementation of meaningful circularity specifications will enhance final product testing protocols leading to the development of more robust manufacturing processes.

.png)

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical.

For more information on this source, please visit Malvern Panalytical.