|

Sub-One has developed a patented process as well as state-of-the-art systems for depositing its advanced coatings onto the internal surfaces of a broad spectrum of products. These products can range from small, complex components to long, large-diameter industrial piping. Pipe coating and combating pipeline corrosion are, in fact, among the largest applications for this technology.

Features and benefits of Sub-One’s Coating Technology

Sub-One’s unique, patented solution provides a spectrum of unprecedented features and benefits:

- Coats internal surfaces and cavities

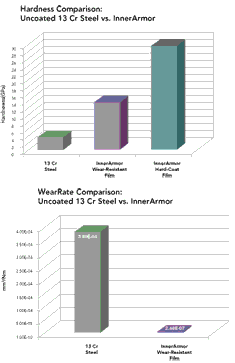

- Is extremely hard and smooth

- Is multi-layer, amorphous and pinhole-free

- Is chemically inert

- Blocks corrosion and erosion

- Minimizes friction and wear

- Maximizes flow

- Lowers materials and installation costs

- Increases service life

- Reduces maintenance and operation costs

- Protects purity

- Protects the environment

Ideally Suited to Fluid, Gas and Materials Flow

InnerArmor technology is a breakthrough for industries utilizing fluid, gas or materials flow

Many industries (oil and gas, food processing, pulp and paper, medical, semiconductor, aerospace, geothermal and public utilities, to name a few) make extensive use of pipes, valves, chambers, cylinders and other parts through which fluids, gases or materials flow. Often, the internal surfaces of these parts require special properties such as corrosion resistance, hardness, smoothness and purity. Up until now, there were only two basic ways to address those needs:

1. Manufacture entire parts from expensive high-grade special alloys and metals, or

2. Use traditional means, such as electroplating, to try to strengthen the interiors of the products. Both are problematic…

The problem with option one is that high-grade materials are expensive - and they are still vulnerable to corrosion, erosion, wear, etc. The problem with option two is that conventional coating technologies are primarily designed for external surfaces. Also, they are limited in effectiveness, relatively expensive and often toxic or environmentally dangerous. Sub-One’s InnerArmor technology eliminates those problems - and can save many billions of dollars of cost for many industries.

Broad Appeal of InnerArmor Technology

InnerArmor can be used to great advantage in many sectors - for corrosion control, as wear-resistant coatings and for the many other benefits this unique technology can deliver.

|