Malvern Panalytical is a leading supplier of analytical solutions for particle characterization and rheological applications. Advanced measurement technologies are combined with robust mechanical designs and comprehensive data handling and automation software, to provide systems that are relevant across a wide range of industrial and fundamental research applications.

Material characterization data such as size distribution, particle shape, zeta potential, molecular weight and bulk material properties, can be accurately and reproducibly measured using instruments from the Malvern Panalytical range. Technologies used include laser diffraction, image analysis, laser Doppler electrophoresis, static and dynamic light scattering, capillary rheometry and strain controlled and stress controlled rheometry.

Benefits and Features of Rheometers

The features of a rheometer and the benefits they confer, together with the instrument’s performance specifications, are obvious and important considerations when purchasing a new system. However, unless you are an experienced rheometer user, written specifications can be confusing and in the worst case may even be misleading. It is not uncommon for an instrument to have the best technical specifications on paper but still be outperformed by another rheometer with seemingly inferior capabilities.#

Some Manufacturers are more aggressive than others when listing specifications, and these are likely to have been provided under idealized conditions. Such conditions may bear little resemblance to those needed for characterizing your specific materials. In order to ensure you are comparing ‘apples with apples’ it is advisable to discuss instrument specifications with your vendor.

Purchasing a Rheometer - After Sales Service and Support

It is worth considering whether you are really happy for your primary support to come from a supplier’s (perhaps non-expert) sales organization. Will their priorities be in line with yours? Can you exploit the full potential of this rheometer based on initial training from a Sales Representative? Someone who may be more used to giving demonstrations to achieve a sale than to capture research grade data or gain a fundamental, detailed understanding of the intricacies of the application?

The outdated model of a Salesperson as a ‘jack of all trades’ was common in the analytical instrument industry when it was growing rapidly and when support was much less of an issue. Today there are many thousands of instruments in industry and academia, and users need and demand more focused and specialist attention. A company that has expert personnel, and which delivers professional support through a variety of different channels, is best placed to help individual customers achieve the maximum return from their rheometer investment.

Significantly, the Salesperson is no longer seen by most instrument users as the primary support channel, with most now demanding:

- a well-staffed help desk with highly trained Advisors to act as a live first point of contact

- exceptional support made available to customers 24/7 via the web

- Specialists who spend 100% of their time working on a particular technology area

How often as a consumer have you been led to believe that your presale experience would be replicated post-sale? And how many times has this really proved true? It is essential to consider more than simply the presale experience in your decision-making. Your company will probably use this equipment for seven to ten years or more, and over that time you are likely to need interaction with, and support from, many more people than only your local Sales Representative.

Future-Proofing Your Rheometer Investment

This means how safe is your decision to get a product today, and how will this decision look one, three, five or seven years from now? This is an often neglected consideration when buying a new piece of equipment - it is more natural to make a decision based on today’s snapshot of the product. Many of us will have bought a product in a store, only to quickly find that the technology has moved on and last month’s new, high-end gadget is no longer the latest, greatest product on the market.

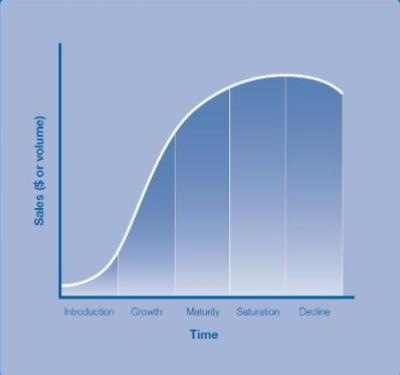

Often in the consumer market the lifetime of the product we are purchasing is not expected to be seven, ten or more years. But if you were spending your own money on a rheometer, wouldn’t you be very careful to ensure that your purchase reflected not only the right decision now, but also the right decision as far as possible into the future? Manufacturers often discuss product lifecycles, or the stages a product goes through during its life - see the graph below for more detail. In order to ‘future proof’ your investment in an analytical instrument, and to look out for your company’s best interests, consider which stage the products you are evaluating have reached.

Getting an objective answer from a specific vendor may well be difficult, but there are ways to evaluate this. Ask the vendor - “for how long has this specific model been on the market?” - if the answer is three to five years, you can reasonably assume the product is in the maturity/saturation/ decline stages of its lifecycle. You then need to consider whether you see this as a good or bad thing. Will the vendor continue to develop and evolve the technology so that you can benefit from new innovations in hardware and software? Or is there a risk that the vendor is already designing a newer platform and you be notified that your equipment is now considered ‘obsolete’ and support will no longer be offered? Only you can decide if this aspect is important to you, and the impact on your reputation if you were to buy equipment that quickly became outdated or not serviceable.

Figure 1. Graph showing sales vs. time.

Purchasing Your Rheometer - A Long Term Investment

How stable is the company you plan to buy from? How long has it been around, how established is its team and what is the ownership status of the company? Is it a small, specialist company, and can it ride out the ups and downs of the global economy, and weather any storm? How important is it for the vendor to have a worldwide presence, in case your long- term plan is to roll out this technique as a standard test method to your various facilities around the world?

Some companies will have a big name through which they can claim a global presence, but can their specialists in the various countries provide a dependable level of support to your company, in every location? How likely is the vendor to provide a consistent, trouble-free experience, pre and post sale, when the equipment is used globally?

Total Cost of Ownership of Your Rheometer

Clearly an investment of this type involves a large outlay of money and an implied commitment on the part of both the vendor and customer to work together over the lifetime of the investment. If you take the view that purchasing a rheometer truly is an investment and not just a quick impulse decision, then it is essential to consider not only the purchase price, but also other costs over the instrument’s life - support, repair/service, training, parts, service contracts, accessories, and upgrades, for example.

It pays to be very wary of vendors who appear to offer large discounts from an initially (often artificially) high instrument price. While their price may be lower ‘today’ the concept of ‘Total Cost of Ownership’ is becoming an increasingly important subject for senior management in companies of all sizes. So while a large discount up front is more friendly to ‘today’s capital budget’, if you are then subjected to inflated costs on some or all of the other items over the life of the equipment, you can easily have a disappointing total cost of ownership (TCO) to explain.

Features and Capabilities of Your Rheometer

This is a common issue in technology today, where products are oversold and claims are made about features that sound impressive but are difficult (if not impossible) to implement. The same happens in the analytical instrumentation industry, where products are sold on ‘bells and whistles’ that sound great, but in practice it may not be possible to use the feature for a given application.

Is there equipment in your laboratory like this, supposedly able to perform some type of measurement but actually needing additional (expensive) accessories, or the capability is difficult to implement and/or is so poorly documented that you finally give up? The end result is severely underutilized equipment that is employed in such a simple fashion that it almost seems a shame, and certainly like a waste of money. You would be well advised not to be drawn into the ‘feature & specification’ dump. This is classic overselling, providing features and specifications that work much better in catalogs than on the instrument in question. Also be confident that the vendor you choose has enough applications staff to support you in future as you work towards expecting more and more from your equipment, not less and less.

Generating Good Quality Rheological Data with Your Rheometer

Our research shows that one of the most frustrating aspects of working with a new rheometer is how long it takes to generate good quality rheological data on an unknown sample, especially when it seemed so easy during the demonstration. Once the vendor representative has completed the initial installation and training - often on a standard calibration material - and then left your premises, the situation can change quite dramatically.

The first question is usually about what sample preparation is needed, followed by how to choose the correct measuring system, then what are the proper conditions for stress, strain, frequency, amplitude, etc. After that the test starts, raising a whole new set of issues. Was the non-ideal looking graph real or the result of some testing artifact? What parameters should be plotted to present data in the most useful, informative way? Suffice to say, these frustrations can often lead an operator to find the simplest, quickest test conditions to run, but these may not be the best or most informative conditions for characterizing the material. In short, the user knows what type of results they want to achieve, but is often much less familiar with how to build the proper test protocols and methodologies to achieve success.

Think back to when Microsoft first introduced ‘Wizards’, or templates for producing a business letter, fax, email, agenda, or even a Powerpoint presentation. This was a radical shift in concept - it enabled customers who knew what end-result they wanted to more easily build the proper protocols and methodologies. Strangely, very few instrument companies have software platforms that are as ‘customer-focused’ as this. So it is good advice to ask for answers to not only the simple questions like “can your unit do this” or “can your software do that”, but also how quickly your operatives can get results directly beneficial to your application requirements.

Choosing the Right Rheometer

With a properly designed rheometer, you can certainly get the best of both worlds, without any need for compromise. Gone are the days when a sophisticated rheometer required a dedicated Ph.D. Materials Science / Chemical Engineering to capture and report high quality data. Also gone is the time when world class Rheologists had to get their graduate students to piece together custom hardware and electronics in order to generate world class rheological data. Modern rheometers are designed with both groups in mind, where the software is quite literally the interface that can ensure even the most complex tests imaginable are performed simply, and that simply-designed test protocols can yield complex material properties.

Instrument Manufacturers experienced in working in complex and highly regulated global industries will often have the edge here, bringing to instrument development the deep knowledge and understanding built from many years designing hardware and software to meet specific industry needs. They appreciate, for example, that multiple operators at different locations may need to carry out the same test protocols, that data consistency is paramount whatever the location and level of operator skill, and that the instrument needs to guide the user.

Analyzing Current and Future Rheological Samples with Your Rheometer

This is hard to predict, given the pace of change in business today. Ideally, the best advice is to remain as flexible as possible in order to cope with acquisitions, divestitures, expansions, restructuring and so on. Positive management will always involve looking to the future and preparing for all reasonable eventualities.

If you are in a frequently changing or unpredictable business environment, you know that you must be prepared for all that may come your way. In this scenario you may want to consider the longer term potential for your instrument, and how flexible the platform design is to cope with your changing test requirements.

Productivity and Return on Investment of Your Rheometer

If they are, then there are even more issues to consider before making a substantial capital investment. Some approaches to improve the odds of achieving a significant productivity increase or a positive ROI include:

- ask the vendor(s) how the buying process typically works before the sale, and how support will work after the sale (is it based on one or few individuals, or a team of people)

- ask for a demonstration, perhaps remotely in the early buying stages (to maximize time efficiency), and live/in person later in the process

- ask the people who do the work every day for their recommendations

- align your long term goals with your purchasing requirements (don’t decide based solely on the ‘better mouse trap’)

- be sure the vendor really understands your application and has prior experience with it

- be upfront with the vendor in terms of your expectations from buying and using the equipment

- define clearly what needs to be accomplished from the new system

- evaluate the system holistically, rather than focusing on a single attribute

Remember, you are not simply buying a new rheometer but rather making an investment in the company who will be supplying it. Be sure that your post sale experience does not depend on one individual, but involves a team of people who can help. Competence is key. In this day and age it is less useful to have someone very close by, but who can’t provide the support you need, than it is to have access to people who can assist quickly, even if they are further away. Technology has reduced geographic boundaries and they no longer present truly forward-looking, global companies with any obstacles to providing world class support.

Making The Decision on Which Rheometer is Right for You

These issues are fundamental to the way in which many people make complex buying decisions. Aside from the obvious features/benefits comparisons, how do you go about weighing these factors (risk vs. reward and pros vs. cons)? Are you motivated to make the safest, most conservative decision possible, to lessen the chance of failure? Or, are you motivated by the upside, trying to get the ‘biggest bang for the buck’, since you want to make the biggest difference you can within your company or organization? Further, do you find comfort in the ‘follow the herd’ mentality, believing there is security in knowing you are not alone and therefore, to a degree, are safe? Finally, are you sometimes called a rebel or non-conformist, simply because you do not put great emphasis on what others do, and are independent thinking and confident enough to make decisions and live with the consequences?

In any case, you and you alone must answer these questions, even if you are part of a decision-making team. We hope this guide provokes your thinking beyond merely ‘buying a product’, recognizing that your organization is looking for the ‘right’ decision, not necessarily only the best product. After all, technology today (and rheological instrumentation falls into this category) is such that products are often separated only by inches and not the miles of the past, so intelligent capital investment decisions have to take account of many additional factors.

Checklists when Purchasing Your Rheometer

As if the purchase of a new rheometer were not complex enough, here are some additional considerations before making that final decision. By thinking these through, your company/organization will appreciate that you made the most well-rounded, objective decision possible, thereby reducing the risks and helping ensure your organization gets the best possible return from its investment.

- Likelihood that the system performs as promised

- Ease of use

- Amount of time/labor saved by using the system

- Total Cost of Ownership (TCO)

- Quality of technical support & customer service

- My importance to the vendor

- Enhanced throughput

- Operator satisfaction with the instrument

- Can the vendor ‘take me to another level’ with this technology?

- Amount of training needed to use properly

- Whether it offers enhanced capabilities/benefits vs. our previous systems

- Level of usage by staff other than the main operator

- Quality and forms of training offered by the vendor

- Ability to help attract new clients, grow revenue, lower costs, etc.

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical.

For more information on this source, please visit Malvern Panalytical.