Malvern Panalytical is a leading supplier of analytical solutions for particle characterization and rheological applications. Advanced measurement technologies are combined with robust mechanical designs and comprehensive data handling and automation software, to provide systems that are relevant across a wide range of industrial and fundamental research applications.

Material characterization data such as size distribution, particle shape, zeta potential, molecular weight, and bulk material properties, can be accurately and reproducibly measured using instruments from the Malvern Panalytical range. Technologies used include laser diffraction, image analysis, laser Doppler electrophoresis, static and dynamic light scattering, capillary rheometry and strain controlled and stress controlled rheometry.

Designing and Interpreting Rheological Tests to Optimize Sample Stability

The following ten points highlight general methods of designing and interpreting rheological tests to optimize sample stability. These points are particularly applicable to colloidal systems (for which the size of the dispersed phase is <1µm) such as:

- Emulsions i.e. liquid-in-liquid systems such as routinely used in paints and coatings, foodstuffs, adhesives, agrochemicals, cosmetics, personal care and pharmaceutical formulations

- Sols i.e. solid-in-liquid systems such as inks, paints and coatings, food and drink, cosmetics and personal care and pharmaceutical formulations

Even classical non-colloidal systems such as large particle (> 1µm) dispersions, including applications of the type mentioned above, as well as mining and mineral slurries, cement and ceramics, can also be evaluated with the same methods. Each test focuses on one property of the material and discusses optimization to help facilitate sample stability.

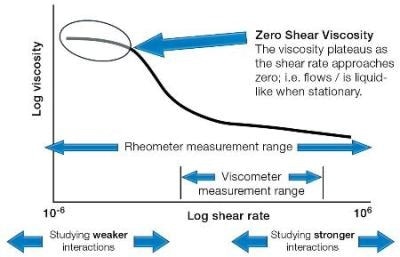

Zero Shear Viscosity

The zero shear viscosity is the viscosity of a material at a shear rate of zero; in other words the viscosity at rest which is typically the conditions to use when studying stability. The material is undergoing no significant deformation forces apart from that of gravity.

The higher the viscosity at lower shear rates, the higher resistance there is for any suspended particles to sediment (i.e. flow) to the bottom of the sample.

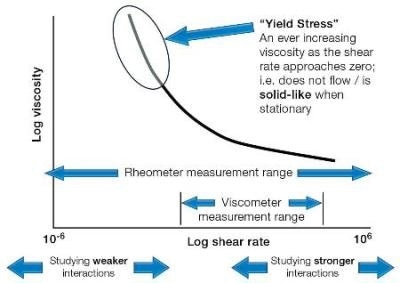

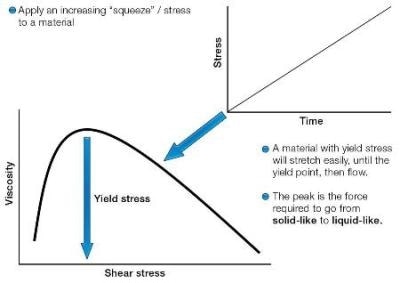

Yield Stress of a Material

The highest zero shear viscosity possible would be infinity – basically a very weak solid! This is an infinite resistance to flow under no shear stress, which is the definition of yield stress. Introducing a yield stress to a material will effectively make the material behave like a solid at rest which by nature resists any suspended material from settling.

Yield Stress and Stability of a Suspension

A yield stress typically signifies a solid like behaviour at rest which can inhibit settling. However, the actual yield stress value itself can have a range of values; the higher the value, the more resistance this structure has to settling. A suspension will therefore be more stable with a higher value of yield stress.

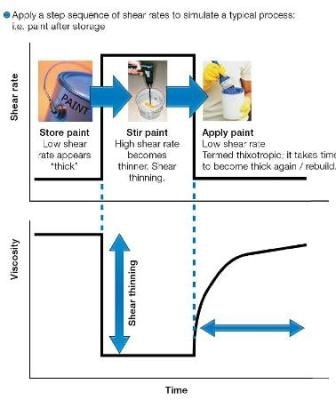

Thixotropy and Viscosity

Even though stability is effectively a process at rest, most materials are transported or moved from one place to another. When this happens forces / conditions more severe than at rest can occur. Typical dispersion systems are shear thinning, so the viscosity will reduce under these conditions which can increase the ability of the material to settle. By minimizing the thixotropy you can minimize the time the sample stays at these low viscosities.

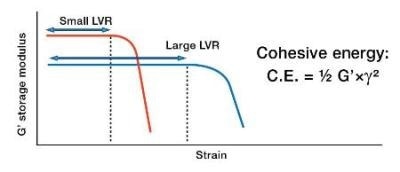

Cohesive Energy

The cohesive energy is a measure of the elastic strength of the material. As the elastic strength is basically a measure of the strength of the internal structure, the higher the cohesive energy the more stable a system is. The cohesive energy can be calculated by recording an amplitude sweep on the material and then taking the strain limit of the Linear Viscoelastic Region (LVR), squaring it, and multipying it by half of the magnitude of the storage modulus in the LVR.

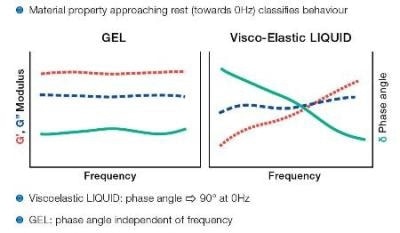

Viscoelastic Characteristics of Gels

By recording the viscoelastic spectrum of the material with a frequency sweep, the materials properties under different time scales can be recorded. As sedimentation and settling is a long time scale process, it is necessary to study what happens at reducing frequencies. Viscoelastic liquids tend to have the worst stability (everything else being equal), as under low frequencies the phase angle is increasing. A high phase angle indicates that the material, and therefore the suspended particles, can flow and settle if you leave it long enough.

To lessen this effect, a gel like system, where the phase angle is independent of frequency, will show a more solid-like behaviour at low frequencies. Having a gel with a high phase angle will still give a material with some liquid like particles at the higher frequencies if that is required.

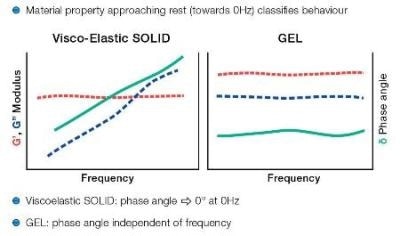

Viscoelastic Characteristics of Liquids

Although a gel like sample can show improved stability than that of a viscoelastic liquid, for some systems with large or heavy particles, this gel structure might still be insuffient to prevent sedimentation. In this case a viscoelastic solid-like response from a frequency sweep, will mean that at the low frequencies (where settling occurs) the phase angle approaches zero. A low phase angle indicates that the material behaves like a solid. So the lower the phase angle, at lowering frequencies will show the most viscoelastic solid-like characteristics, which will be inherently a more stable system.

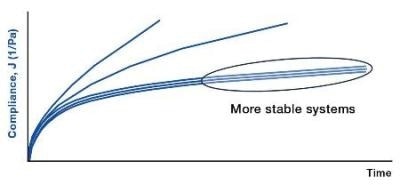

Creep Test

A creep test allows a materials resistance to flow under small constant forces, such as gravity, to be determined. Using a creep test to apply a small force, is a very sensitive measure of how the material will resist the force of gravity; the smaller the resultant movement (strain) the less likely it is to be unstable.

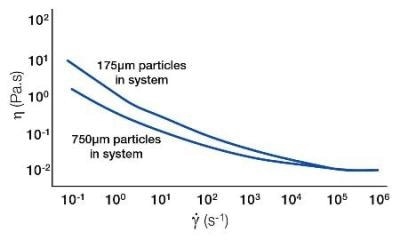

Low Shear Viscosity and Particle-Particle Interactions

Low shear viscosity (such as zero shear) is affected by particle to particle interactions. Therefore, to increase the number of particle-particle interactions you simply need to increase the number of particles in a system. This can be easily achieved by making the particles smaller, so for the same given mass of particles there will be more particles.

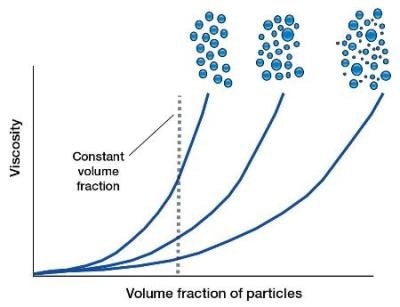

Low Shear Viscosity and Particle Size Distribution

If it not possible to change the average particle size in the system, a change in particle size distribution can also affect the low shear viscosity, and therefore the stability. Particles which have a wide span / distribution (large polydisperity) tend to pack better than a system of particles with a narrow distribution. This basically means that for a wide distribution, particles have more free space to move around, which therefore means it is easier for the sample to flow, i.e. has a lower viscosity. So, tightening up the particle distribution (i.e. reducing the polydispersity) can increase the stability of a system.

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical.

For more information on this source, please visit Malvern Panalytical.