Originally treated as a waste product by the oil refining industry, wax is now broadly used in manufacturing because of its specific mechanical and physical properties (flexibility, friction index, hardness coefficient, melting point, etc.). The oil refining industry has reacted by producing a wide range of wax with special characteristics (petrolatum, slack, crude paraffin, recrystallised paraffin, blend, etc.). The oil content is an important parameter in the composition of wax since it affects its physical properties. Therefore there is a strong interest in being able to measure it on a routine basis.

Method

The official oil in wax method (American Society for Testing and Materials (ASTM) D721-06, IP158/69 (01)) involves dissolving the oil in methyl ethyl ketone, then precipitating the wax at low temperature (-35 °C). The technique is slow (the process takes about 2 hours) and requires technical skills and the use of hazardous solvents. In comparison, benchtop nuclear magnetic resonance (NMR) offers rapid, user-friendly, safe and reliable analysis in response to the increasing demand for Quality Control (QC) in routine operation. The Oil in Wax NMR method is a ratio method so the sample does not need to be weighed. Generally, the Oil in Wax NMR method can exploit two different hardware configurations to optimize for two ranges of oil content dependent on the sample and/or user requirements:

- 2% and above: rapid measurement using a standard MQC with 10-mm diameter samples and sample pre-conditioning at low temperature (usually –5 °C).

- 0.1% to 2% oil: low detection limit measurement using an MQC with 10-mm diameter samples and equipped with a low-maintenance, fluid-cooled temperature-regulated probe (usually –5 °C or less).

Experience shows that different types of wax may have different physical, and consequently NMR, properties which may need to be calibrated separately.

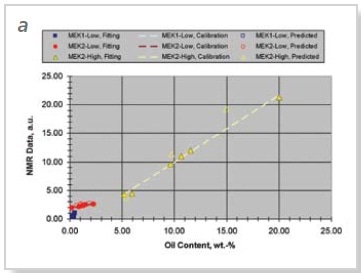

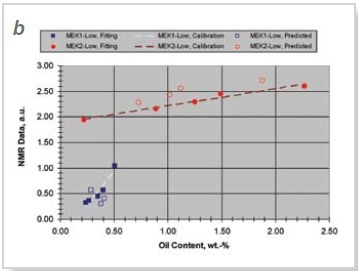

For example, figure 1 shows the results for a set of waxes which were separated into three different calibrations depending on the oil content and wax type. The MultiQuant software is versatile. Calibrations can be optimized after the reference samples have been measured and do not have to be measured again to produce different calibrations. It is good practice to recalibrate the instrument regularly, especially if new wax products need to be measured.

Figure 1. Graphs showing calibration data for (a) all, and (b) low oil content wax samples. Solid symbols represent data points accounted in calibrations and used for fitting; open symbols correspond to data points excluded from fitting to improve standard deviations and correlation coefficients of the calibration procedure; dashed lines are the calibration curves.

Advantages of Benchtop NMR

The benefits of benchtop NMR are:

- NMR is a very stable technique over the long-term and therefore needs minimal re-calibration operations.

- Minimal sample preparation is required.

- No solvent extraction is required.

- The NMR technique is non-destructive, so the repeatability of measurements is extremely convenient.

- Sample measurement time is short (typically 1-2 minutes).

Calibration and Results

The NMR technique requires calibration of the signal against the oil content (%) from an appropriate reference method, e.g. solvent extraction technique (e.g. ASTM D721-06). Ideally each calibration requires a minimum of six samples that span the concentration range of interest.

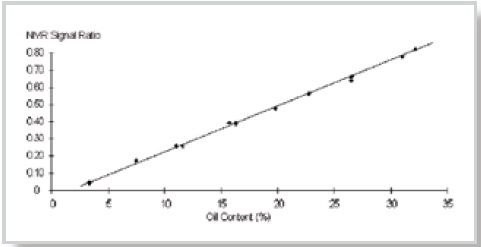

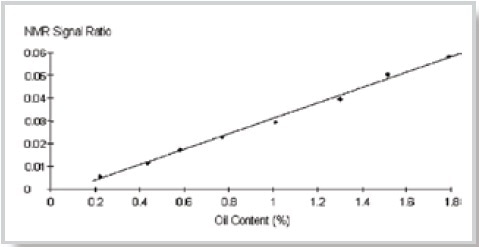

Figure 2 shows the linearity and the precision of the NMR calibration curve for petrolatum in the oil range 10-40% as determined by the official ASTM method. Figure 3 shows the precision and linearity of the calibration curve for hard wax at low detection limits, showing that measurements can be achieved below 1% oil (low detection limit method).

Figure 2. NMR signal ratio versus oil content in petrolatum. Analysis time ~ 20 s. Mid-range measurement precision (95% confidence) ~ 0.1%. Calibration error ~ 0.1%.

Figure 3. NMR signal ratio versus oil content in hard wax (low detection limit method only). Analysis time ~ 2 min. Mid-range measurement precision (95% confidence) ~ 0.05%. Calibration error ~ 0.07%.

Recommended Instrument Configuration

The MQC-23 (0.55 Tesla), either controlled by its own Microsoft Windows operative system or by a stand-alone PC, for oil contents 2% and above includes the following features:

- A standard 10-mm diameter (2 ml) hydrogen probe.

- The method requires a refrigerated water bath and aluminium block with holes for sample conditioning at low temperature (usually –5 °C) or for oil contents 0.1% to 2%. (Note: a supply of dry air is also required for a temperature regulated probe operating below ambient temperature to prevent condensation which will cause errors in the results).

The Oil in Wax package also comprises:

- MultiQuant software including RI Calibration, RI Analysis, and the EasyCal ‘Oil in Wax’ application.

- 10-mm diameter glass tubes.

- Installation manual.

- Method sheet.

Benefits of the MQC-23

The instrument offers multiple advantages over other instruments on the market:

- High signal sensitivity.

- Small benchtop footprint.

- “Specific Oil in Wax” applications software.

- Minimal sample preparation.

- Low maintenance.

This information has been sourced, reviewed and adapted from materials provided by Oxford Instruments Magnetic Resonance.

For more information on this source, please visit Oxford Instruments Magnetic Resonance.