Jul 23 2001

Alexander A. Nedviga / Shutterstock

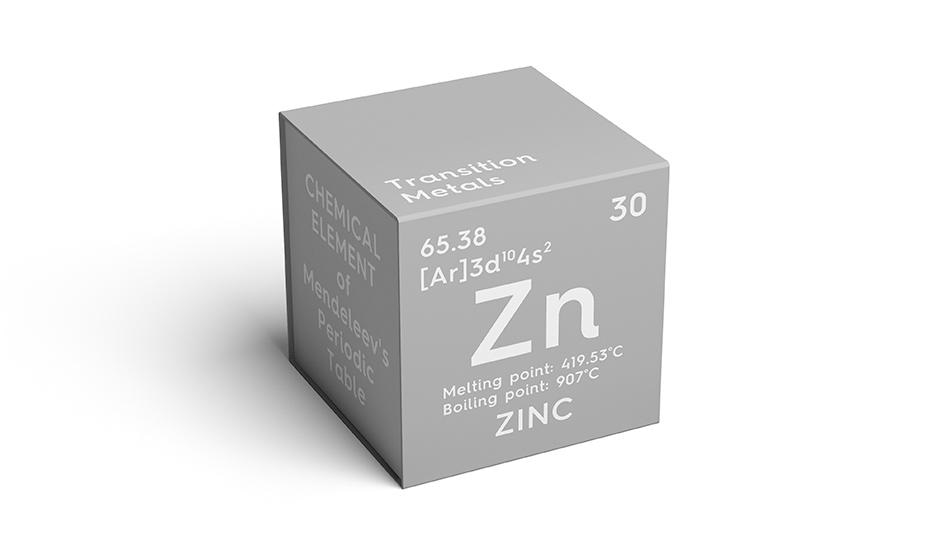

Metallic zinc was produced in India by reducing calamine with organic substances like wool, in the 13th century A.D., Marggraf rediscovered zinc in 1746 and showed that metallic zinc could also be synthesized by reducing calamine with charcoal.

Occurrence

Calamine (silicate), sphalerite or blende (ZnS), franklinite (zinc, iron oxide, manganese), and smithsonite (ZnCO3) are the primary ores of zinc. Zinc can be synthesized by roasting its ores to form zinc oxide, and then reducing the oxide with carbon or coal. The metal is subsequently distilled.

Five stable isotopes of zinc occur naturally, and 16 unstable isotopes are also recognized, half of which is zinc 64. In natural zinc, 4% of the stable isotope zinc 67 is present.

Zinc is a blue-white, shiny metal. At normal temperatures, it is brittle, but at temperatures of 100 °C to 150 °C, it is malleable. It is a moderate conductor of electricity and ignites in air, emitting intense red heat along with white fumes of the oxide.

When zinc is exposed to air, a film of carbonate forms on its surface, making it highly resistant to corrosion.

Applications

Zinc is used for the following:

- Plating and galvanizing

- Making nickel silver, brass, and bronze

- Die castings

- Electronics

- Electric batteries

- Alloyed sheets for gutters, flashings, and stamped and formed parts

Due to the 99.99% purity of cathodic zinc, it is used on hulls of ships/ocean-going vessels or fixed to underground pipelines to minimize electrolytic corrosion.

Zinc powder is used as a reducing agent and catalyst, in paints, and in pyrotechnics. Moreover, it is used as a secondary dispersing agent and to enhance flexing in rubbers, as well as to produce sherardized steel.

Zinc alloys are used in applications like auto and appliance parts, die-castings for decorative parts, novelties, locks, hardware, and toys.