One of the most common issues with respect to adhesives in High-tech manufacturing industries involves the outgassing characteristics of adhesives and related encapsulation and sealing compounds. And that’s understandable because a growing number of high-tech industries have discovered that their products and manufacturing processes can be sensitive to outgassed chemical compounds. As a result, there has been a dramatic upswing in the use of adhesives, encapsulants and sealants that have been specially formulated for low outgassing performance.

While it’s true that some standard adhesives do have good outgassing performance “right out of the tube,” today’s most stringent outgassing requirements are best met by products formulated to pass an industry-standard outgassing test known as ASTM E595-07.

The test’s full title is “A Standard Test Method for Total Mass Loss and Collected Volatile Condensable Materials from Outgassing in a Vacuum Environment” (see sidebar).

And engineers working on projects for NASA already know all about it. For years, they have been specifying ASTM E595-compliant adhesives and other materials for use in space systems.

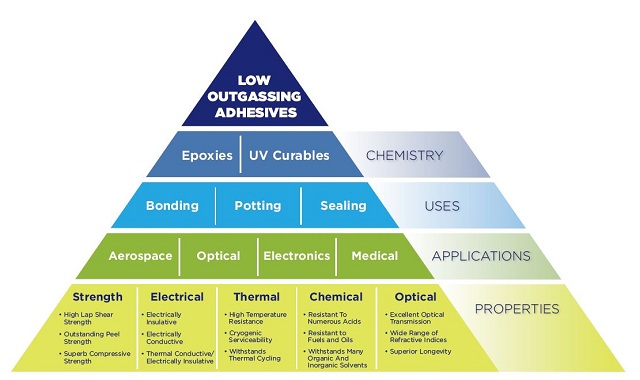

Now that a growing number of engineers with earthbound applications are worrying about outgassing too, Figure 1takes a look at what to expect from low outgassing adhesives, encapsulants and sealants.

Figure 1. Adhesives that have passed the industry-standard outgassing test (ASTM E595) offer a range of physical properties tailored to aerospace, optical and electronic applications.

Measuring Outgassing from Adhesives

The industry-standard test for measuring outgassing in adhesives and other materials is ASTM E595. Developed by NASA to screen low-outgassing materials for use in space, the test determines the volatile content of material samples placed in a heated vacuum chamber.

Samples to be tested are first preconditioned at 50 percent relative humidity for 24 hours and weighed. They then go into the test chamber for another 24 hours with the temperature set at 125 C and the vacuum at a minimum of 5 x 10-5 torr. During that time in the test chamber, volatiles that outgas from the sample escape through a port in the test chamber and condense on a cooled (25 C) collector plate.

The sample and condensate on the collector plate are then weighed to determine the total mass lost (TML) by the sample and the amount of collected volatile condensable materials (CVCM) on the collector plate.

Materials pass or fail the test based on these TML and CVCM measurements. If the CVCM exceeds 0.1 percent, the material fails. The material will also fail if the TML exceeds 1 percent—though the TML may be offset by water vapor regained (WVR) by the sample in a subsequent measurement:

- If CVCM <0.1 percent and TML < 1 percent, the material passes.

- If CVCM <0.1 percent and TML > 1 percent, the material can pass if the TML-WVR <1 percent.

- If CVCM > 0.1 percent or TML-WVR > 1 percent, the material fails.

While you will occasionally run across proprietary outgassing test methods, their results should not be considered credible. ASTM E595 currently represents the only widely accepted industry standard for quantifying the outgassing performance of adhesives. The test does have its limitations. Among them, this 24-hour test doesn’t predict long-term outgassing performance. Nor can it determine what specific outgassing contamination, if any, will occur in real world operating conditions. Despite these limitations, though, the test is a good way to evaluate and compare the outgassing potential of adhesives and other materials.

Master Bond has developed UV-curable adhesives that pass ASTM E595, something these fast-curing adhesives have traditionally not been able to accomplish.

This development brings the assembly speed of UV-curable adhesives to outgassing-sensitive applications.

Masterbond UV-Curable Adhesives designed to pass ASTM E595

Applications for Low Outgassing Adhesives

The first thing to understand about low outgassing products is when to use them (see Figure 2. “Typical Outgassing Applications” for a full list). Other than space systems, the most common applications for low-outgassing products are those that involve optical or electrooptical components, which can be clouded or fogged by outgassed chemical compounds. Outgassing can also affect some sensitive electrical processes—by interfering with electrical continuity. Semiconductor manufacturing processes can be very sensitive to outgassing material systems. And commercial vacuum processes can also suffer from outgassing issues.

If you suspect outgassing could potentially pose a problem in your application, specifying adhesives that comply with the ASTM outgassing standard will make sense as long as one of the compliant grades meets all of your other technical requirements. And the good news here is that low outgassing adhesives don’t typically require any sacrifice in other mechanical or physical properties. What sets low outgassing products apart from their generic counterparts is that the low outgassing grades have passed the rigorous ASTM test—often after months of painstaking formulation work on our part.

The time and expense of all that testing and custom formulation do not have major cost implications for users of low outgassing products. The compelling reason to carefully consider whether you truly need a ASTM E595- compliant grade comes down to freedom of choice, not cost.

Consider that Master Bond has hundreds of adhesives that have not been tested for low outgassing and over 20 adhesives that have. By picking an ASTM E595-compliant grade when you do not need one, you may limit your ability to find the best match between your application requirements and adhesive properties. For this reason, engineers should stick with standard products for bonding, sealing, encapsulation and potting applications that have no known sensitivity to outgassing.

With that caveat in mind, the compliant adhesive products available today do cover a wide range of capabilities for those times when nothing else will do (see Figures 1 & 2 and Table 1).

Master Bond offers ASTM E595 products for structural bonding, potting, encapsulation and sealing. Also available are E595-certified electrically and thermally conductive products as well as medical and cryogenic adhesives. Recently, Master Bond introduced a UV-curable adhesive, one of the first in the industry to pass the standard ASTM E595 test.

- Disk drive assemblies

- Voice coil motors

- MEMs devices

- High-vacuum applications

- Solar arrays and panels

- Fiber optic assemblies

- LEDs

- Optical telescopes

- Reflectors

- Respirators

- Space systems

- Spectrometers

- Optics used in aircraft and space applications

- Lens mounts and prisms

- Wavelength-division multiplexing (WDM) applications

|

- Medical filter applications

- High-power voltage supplies

- Optoelectronic assemblies

- Piezo devices

- Clean room applications

- Satellite assemblies

- Electronics underfill applications

- Laser applications

- Mirrors (including mirrors for telescopes)

- Bonding voice coil to

- suspension arm

- Broadband and high-frequency RF power applications

- Avalanche photodiodes (APDs)

|

Figure 2. Typical Applications for Low-Outgassing Adhesives

Outgassing Tendencies

When looking for low-outgassing products, keep in mind that not all adhesives start on a level playing field when it comes to passing ASTM E595. Some adhesives, such as two-part epoxies, can be specially formulated to achieve outgassing levels well below what ASTM E595 requires.

Other types of adhesive chemistries have traditionally not been able to pass ASTM 3595. UV-curable adhesives once fell into this category, which kept these fast-curing adhesives out of some otherwise suitable applications.

Only recently have Master Bond’s chemists been able to “crack the code” of UV-curables that do pass the test.

The adhesives that outgas most severely are those that cure through the action of solvents or moisture. These would include a variety of pressure-sensitive and contact adhesives as well as cyanoacrylates. These types of adhesives are not the best choice in applications that have a known sensitivity to outgassing.

It’s worth noting that even within a given family of adhesives, the outgassing potential of the individual adhesive grades can vary substantially. This variance results from the optimization of each grade’s physical and mechanical properties through modifications to the underlying adhesive chemistry. To take one common example, the more flexible grades within the epoxy family tend to be

more prone to outgassing—possibly because they have a lower crosslink density than their more rigid counterparts.

At the end of the day, adhesives are best looked at as individuals rather than families when evaluating outgassing performance. And the only way to know for certain whether a specific adhesive meets the low outgassing criteria spelled out in ASTM E595 is to test it.

Popular Low Outgassing Adhesives

Master Bond offers a wide variety of certified low-outgassing adhesives. Some of the most popular grades are described here:

| EP29LPSP |

Low viscosity, cryogenically serviceable epoxy with excellent physical properties for bonding or potting. Withstands cryogenic shocks. Superior electrical insulation

properties. Optically clear. |

| EP21TCHT-1 |

Thermally conductive, two-component epoxy with paste consistency. Cryogenically serviceable. High temperature resistant for bonding and sealing. Cures at room temperature. Service temperature range 4K to 400°F. |

| EP37-3FLFAO |

Thermally conductive, lower viscosity, easy to use epoxy system that cures flexible. Resistant to vibration, impact and shock. For potting and bonding. Cryogenically serviceable. |

| EP30-2 |

Superior physical properties, excellent optical transmission characteristics,

outstanding chemical resistance profile. Low viscosity enables easy application.

Service temperature range 4K to 300°F. |

| SUPREME 10HT |

One part, no-mix system requiring oven curing at 250° to 300°F with extraordinary

physical properties. High peel and tensile shear strength. Cryogenically serviceable.

Resistant to vibration, thermal shock and impact. |

| UV10TKLO-2 |

One component UV curable adhesive/sealant. Exceptionally fast curing. Excellent clarity and light transmission properties. Service temperature range -60°F to 300°F. Easy application. |

| EP21TDC-2AO |

Highly flexibilized thermally conductive two-component epoxy system. High shear and peel strength. Superior electrical insulation and heat dissipation properties. Cures at room temperature. Ideal for bonding dissimilar substrates. Resistant to thermal cycling. |

| SUPREME 10HTS |

High purity silver conductive epoxy adhesive/sealant. Service temperature range from 4K to 400°F. One part, no mix system. Resists vibration, shock and thermal cycling. 100% reactive. High peel and shear strength properties. |

| SUPREME 10AOHT-LO |

Resists up to 400°F. High thermal conductivity and excellent electrical insulation properties. Cryogenically serviceable. One-component, no-mix system. Resists exposure to many chemicals and thermal cycling. Cures at elevated temperatures. Low ionics. |

Table 1. Masterbond Low Outgassing Adhesives Properties and Applications

Cure for Outgassing

When selecting adhesives for low-outgassing applications, engineers often don’t pay much attention to cure schedules. That’s understandable since so many modern adhesive formulations do indeed cure well at room temperature, developing better than adequate mechanical and physical properties for their intended use. Yet the addition of a heat cycle will optimize a host of desirable physical properties—low outgassing among them. With adhesives, in other words, it’s often the case that a room temperature cure is good, but a heat cure is better.

In low-outgassing applications, heat can even be essential. Heat tends to improve the crosslink density, which in turn limits outgassing. Master Bond has seen cases where individual adhesives did not pass ASTM E595 when cured at room temperature but passed after a heat cycle. For that reason, Master Bond recommends the addition of a heat cycle for applications where outgassing performance is critical. A typical cure schedule would be room temperature overnight, followed by 2–5 hours at 60-80 °C.

.jpg)

This information has been sourced, reviewed and adapted from materials provided by Master Bond Inc.

For more information on this source, please visit Master Bond Inc.