Jul 29 2001

Lars Poyansky / Shutterstock

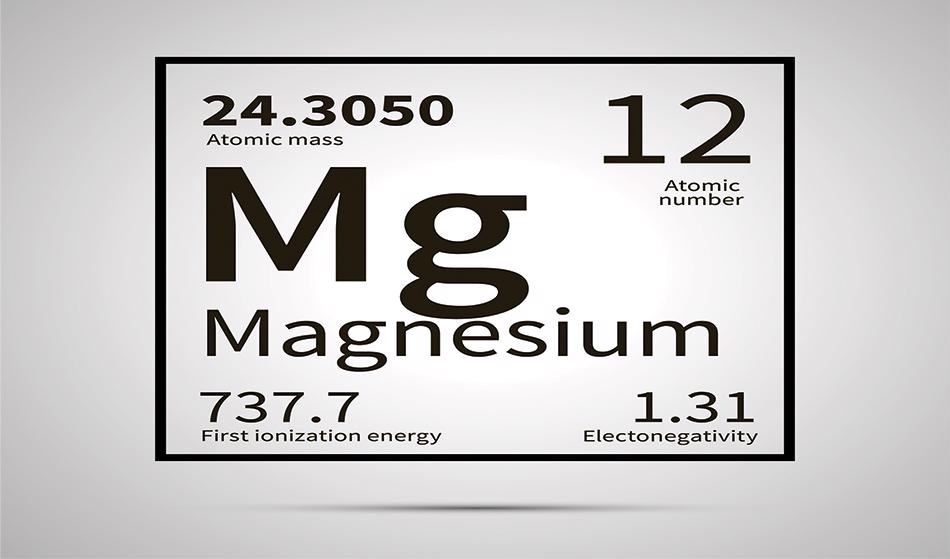

Black was the first person to recognize magnesium (Mg) as an element in 1755. Later, in 1808, Davy isolated this element by evaporating mercury from a magnesium amalgam, which was produced by electrolyzing a mixture of mercuric oxide and moist magnesia. Then in 1831, Bussy successfully prepared a coherent form of magnesium.

Occurrence

Magnesium is an alkaline-earth metal and is the eighth-most abundant element in the Earth’s crust (around 2.5% by weight). It does not occur in an uncombined form.

Magnesium is present in mineral deposits such as dolomite, magnesite (the oxide), chrysolite, serpentine, brucite, talc, meerschaum, magnesia alba (the carbonate), Epsom salts (the sulfate), and most kinds of asbestos. Seawater contains around 0.13% of magnesium—mostly as dissolved chloride—giving it the characteristic bitter taste.

Commercial Production

Magnesium is produced at the commercial scale by electrolyzing molten magnesium chloride (MgCl2), which is processed mainly from seawater, wells, and brines, and through direct reduction of its compounds with appropriate reducing agents (as from calcined dolomite with ferrosilicon).

Key Properties

Physico-Chemical Properties

The major engineering characteristics of magnesium are given below:

- Excellent toughness

- The lightest engineering metal (except for exotic materials like lithium and beryllium) with a density of 1.73 g.cm-3

- It has a moderately high electrical conductivity at around 40% that of copper

- It has a reasonably high thermal conductivity of about 150 W/m.K

- It has a high coefficient of thermal expansion at 25.5x10-6 m/m/°C

- Excellent machinability

- High damping capacity

Environmental Behavior

Magnesium forms a corrosion-hindering film when exposed to clean atmospheres and freshwater, but this film breaks down in the presence of sulfates, chlorides, and other media.

Magnesium is readily attacked by mineral acids, excluding hydrofluoric and chromic acids. However, it is resistant to dilute alkalies, specific alcohols, aromatic and aliphatic hydrocarbons, and dry chlorine, bromine, and fluorine gases. When magnesium is anodized, its corrosion resistance is considerably improved.

Magnesium has a good affinity toward oxygen. When this element is finely divided, it readily ignites when heated in air, and burns with a bright, dazzling white flame. As a result, magnesium should be handled carefully to prevent the risk of serious fires. Water should never be used on burning magnesium or on magnesium fires.

Applications

Magnesium Metal

Metallic magnesium is used in the following applications:

- Cathodic protection of other metals against corrosion.

- Used as an alloying element in lead, zinc, aluminum, and other non-ferrous alloys

- Used as a flashing material in building construction

- Used as a reducing agent for producing pure uranium from its salt

- Used for constructing missiles and airplane alloys used in photoengraving plates, flashlight photography, flares and pyrotechnics (which contain inflammable bombs)

- Ammunition

The alloys of magnesium are used in lightweight applications, sporting goods, auto parts, power tools, aerospace equipment, materials-handling equipment, and fixtures.

Magnesium Compounds

Magnesium and its compounds are used in the following:

- Magnesium methoxide [Mg(OCH3)2] is used to dry alcohol to produce absolute fuels.

- Magnesium nitrate [(Mg(NO3)2.6H2O] is used in pyrotechnics, dry colors, and to produce magnesia.

- Magnesium’s sulfate, chloride, hydroxide, and citrate are utilized in medicines.

- Magnesium fluoride (MgF), or sellaite, with a very low refractive index, is used in lens and instrument windows to prevent reflection.

- Magnesium sulfate (MgSO4.7H2O) is also used in leather tanning, for sizing paper, as a filler in cotton cloths, as a mordant in dyeing and printing textiles, as a laxative, and also in fireproof and water-resistant magnesia cement.

Magnesium carbonate (MgCO3) is also used in insulating coverings for furnaces and steam pipes, in boiler compounds, in the manufacture of oxychloride cement, and as a filler for paper and rubbers.