Induction Technology Corporation (ITC), a provider of novel products and services to the induction melting industry, and Ambrell, which has more than two decades of induction heating experience, have partnered to offer highly efficient induction melting systems depending on the quantity of materials to be melted. This article covers the various ITC melting systems featuring Ambrell induction power supplies.

Melting temperatures and density for common metals are listed in table 1.

Table 1. Melt temperatures and density for common metals.

| Metal |

Melt Temp °F |

lbs./cu. in. |

| Steel |

2516 |

.283 |

| Aluminum |

1220 |

.100 |

| Copper |

1981 |

.320 |

| Gold |

1945 |

.697 |

| Silver |

1760 |

.379 |

| Platinum |

3221 |

.775 |

| Nickel |

2646 |

.321 |

| Zinc |

786 |

.258 |

Melt system selection guide (table 2) provides an idea to customers to select the appropriate system based on their material and melt rate.

Table 2. Melt System Selection Guide.

| Furnace Capacity in lbs./hr. |

Typical Furnace size for steel lbs. |

Max Power kW |

Nominal Operating Frequency kHz |

Melt System |

| Steel |

Aluminum |

Brass |

Copper |

Gold |

Silver |

| 6 |

6 |

11 |

9 |

30 |

17 |

Up to 15 oz. |

2 |

220 |

2.4kW Micro Melt System |

| 30 |

30 |

56 |

48 |

150 |

85 |

Up to 30 lb. |

10 |

220 |

10kW Mini Melt System |

| 45 |

45 |

84 |

72 |

225 |

128 |

Up to 30 lb. |

15 |

60 |

15kW Metal Melting System |

| 150 |

150 |

280 |

240 |

750 |

427 |

100 |

50 |

10 |

50kW Metal Melting System |

| 375 |

375 |

700 |

600 |

1875 |

1068 |

300 |

125 |

3 |

125kW Melting System |

| 950 |

950 |

1800 |

1520 |

4750 |

2707 |

1000 |

250 |

1 or 3 |

250kW Melting System |

| 2000 |

2000 |

3800 |

3200 |

10,000 |

5700 |

2000 |

500 |

1 or 3 |

500kW Melting System |

| 3000 |

3000 |

5120 |

4800 |

15,000 |

8550 |

3000 |

800 |

1 |

800kW Melting System |

The furnace size mentioned in the above chart is the characteristic size for melting steel and may vary for melting other materials.

Bench Top Melting Systems

High Efficiency 2.4kW Micro Melt Bench Top Melting System

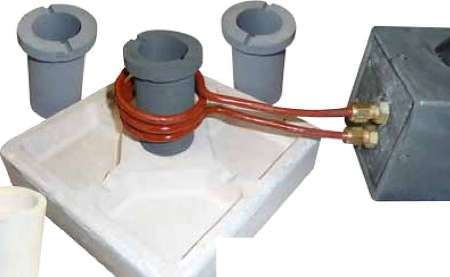

The Micro Melt system is supplied with a spill container, coil for a 4.4 cubic inch crucible, lifting tongs and high temperature insulation.

The Micro Melt bench top melting system is suitable for melting gold or silver scrap, grindings, sweepings, and filings and can melt 15 oz. of gold within 10 min. The versatile melting system features an EASYHEAT 2.4 kW induction heating power supply from Ambrell, a spill container, high temperature insulation and lifting tongs. It can be used with ceramic, silicon carbide or graphite crucibles. ITC helps customers to select the appropriate crucibles for their melting application.

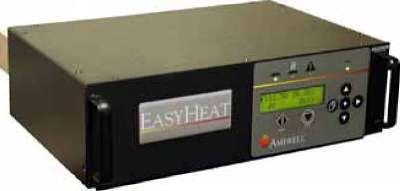

EASYHEAT is a high efficiency solid-state induction heating system that offers a compact, reliable and user-friendly solution for benchtop melting.

EASYHEAT 2.4kW induction power supply.

EASYHEAT 10kW induction power supply.

The EASYHEAT 2.4kW runs from 220 VAC single-phase electrical service and needs a clean water supply at a rate of one gallon per minute for cooling, while EASYHEAT 10kW runs from either a 480 VAC three-phase or a 220 VAC three-phase 220 VAC three-phase a clean water supply at a rate of 1.5 gallons per minute. Both EASYHEATs employ MOSFETS for inverting the power from the 60 Hz AC line and constantly tune over a frequency range between 150 and 400 kHz for increasing heating efficiency.

High Efficiency 10kW Mini Melt Bench Top Melting System

ITC’s handheld furnace for use with the EASYHEAT 10kW. The furnace uses inner and outer crucibles and is used for melting platinum. Shown with optional attachment for a covering gas such as Argon.

The Mini Melt system is a suitable system for melting platinum, silver, gold, ferrous and non-ferrous metals. The versatile, compact and reliable system is compatible with ceramic, silicon carbide, and clay graphite crucibles.

The furnace shown has a graphite crucible for melting gold, silver or non ferrous metals.

High Efficiency 15kW Metal Melting System

The Metal Melting system features a simple nose tilt-and-pour mechanism which utilizes an 80-100 psi air/hydraulic assist for easy pouring. The Compact Power Cube Nose Tilt furnace with a capacity range of between 5 and 30 lbs comprises of a specially designed heavy duty, high-conductivity coil. It is suitable for small melting applications of steel and precious metals utilizing silicon carbide, graphite, clay and ceramic crucibles.

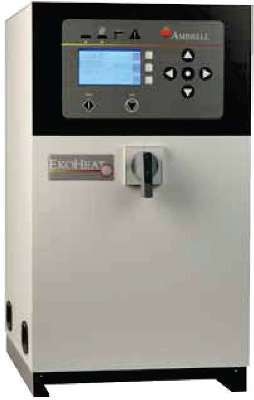

The EKOHEAT 15kW induction heating system utilizes IGBTs for power conversion from the 60Hz AC line and continuously tunes over a frequency range between 50 to 150 kHz for increasing the melting efficiency. The EKOHEAT 15kW runs from a 480 VAC three-phase line and needs water cooling.

EKOHEAT 15kW induction power supply.

High Efficiency 50kW Metal Melting System

100 lb. Power Cube Furnace with hydraulic tilt.

The ITC Power Cube furnace is made of cast refractory top and bottom blocks and cast aluminum side plates, making it durable. It uses high conductivity thick-walled copper coils for improved efficiency. It is offered in 50, 100 or 150 lbs sizes with the 50kW induction power supply based on the metal load to be melted. For tilting, it can be equipped with an overhead hoist or hydraulic tilt cylinders.

The EKOHEAT 50kW bench top induction power supply is offered in models covering 1.5-150 kHz frequency range for a variety of melting configurations that deal with different melting requirements. The EKOHEAT runs from a 360 to 520VAC 50 or 60 Hz three-phase line and needs water cooling.

EKOHEAT 50kW induction power supply.

High Efficiency 125kW and 250kW Melting Systems

Power Cube Furnace shown is the 500 lb. capacity model. ITC builds furnaces sized to fit the customers melting application. Power Cube Furnaces are manufactured with capacities between 50 and 3000 lbs.

The 300 lb. capacity ITC Power Cube is a unique furnace designed for steel melting applications at the 125 kW power level. It is constructed of cast refractory top and bottom blocks and cast aluminum side plates, making it durable. It uses high conductivity thick-walled copper coils for optimal efficiency. It can be equipped with an overhead hoist or hydraulic cylinders for tilting.

The EKOHEAT 125 and 250kW two-bay induction power supplies are offered in models operating at either 1 or 3 kHz based on the metal load being melted. One bay houses the power supply, while the second bay accommodates optional furnace switches and resonating capacitors. EKOHEAT 125 and 250kW run from a 360 to 520VAC 50 or 60Hz three-phase line and need water cooling.

High Efficiency 500kW and 800kW Melting Systems

Power Cube Furnace shown is the 3000 lb. capacity model showing the deck that provides a platform for matching the customers melt deck.

The 2000 lb capacity ITC Power Cube Furnace is a typical furnace designed for steel melting applications at the 500kW power level. The EKOHEAT 500kW and 800kW induction power supplies are offered in models working at either 1 or 3 kHz based on the metal load being melted and the stirring action required. Two bays house the power supply, while the third bay accommodates optional furnace switches and resonating capacitors. EKOHEAT 500 and 800kW run from a 360 to 520V 50 or 60Hz AC three-phase line and need water supply.

Summary

Ambrell will raise a request to ITC to propose an ideal furnace depending on the melting requirement of customers. The company will provide power supply to fulfill melting rates and budget of customers. ITC also helps customers by providing suitable cooling systems for their melting installation.

This information has been sourced, reviewed and adapted from materials provided by Ambrell Induction Heating Solutions.

For more information on this source, please visit Ambrell Induction Heating Solutions.