Efficient storage technologies that are developed for electrical energy play a vital role in the advancement of electromobility.

Such technologies will aid in reducing emissions and enable efficient use of renewable energy since they are employed in smart grids. With recent developments, Li-ion batteries can offer high energy and power densities and hence prove suitable for these applications.

Performance of Li-ion Batteries

Factors like battery power and capacity, energy density, charge and discharge rates as well as the lifespan are used to determine the performance of an Li-ion battery. The functionality illustrated in figure 1 is based on the change of active materials as a result of diffusion processes.

Therefore, the materials’ microstructural parameters tend to affect the performance of the battery next to physical properties such as thermal capacity and expansion, diffusion coefficient, volume change or resistance, or geometrical aspects like the thickness of the electrodes or design and parts of the cell.

Figure 1. Schematic setup of an Li-ion battery. The functional principle is based on diffusion of Li-ions through the separator between the two active materials of cathode and anode.

When it comes to the microstructure of the battery material, the surface area, size and shape of the grains, as well as the volume fraction of phases are considered to be essential parameters. Hence, microstructure characterization of Li-ion batteries is important so as to gain a better understanding about the performance of batteries. Such characterization makes it viable to study the relationship between battery performance and cell design. With the help of quantitative microstructure data, physical models can be developed. Moreover, the visualization of microscopic phenomena as a result of aging history is extremely crucial for reliable analysis. This helps in preventing serious accidents set off by short circuit failures.

Correlative Light and Electron Microscopy

Correlative Light and Electron Microscopy (CLEM) offers a suitable solution for this application as it integrates the optical characteristics of light microscopy (LM) with the structural analysis of the scanning electron microscope (SEM). Light microscopy provides a quick overview of morphology, damaging effects and optical appearance of phases, while scanning electron microscope images provide information about shape, size and chemical composition of particles within the same region. Hence, CLEM is necessary for detailed characterization of battery materials.

Preparation and Imaging of Sample

A standard Li-ion consumer cell was aged for 50 days at 65°C with 4.2 V constant voltage. Then, it was discharged and unlocked in a glove box under argon atmosphere. After removing the electrolyte, the sample was entrenched in epoxy resin and prepared according to materialographic sample preparation protocols. Consequently, the resulting sample was a polished cross-section of the battery. The sample was then mounted into the "Specimen Holder CorrMic Mat Universal A", which is specifically designed for CLEM.

The sample holder can be utilized both in light microscope and scanning electron microscope so that the sample remains fixed onto the holder during the entire imaging process. The sample’s LM imaging was carried out in an Axio Imager.Z2, which is a compound light microscope designed by Carl Zeiss for materials analysis. In addition, an AxioCam HR camera and 20x and 50x objectives were utilized for imaging.

With this assembly, brightfield images in the reflected light mode were acquired with and without polarization contrast. Regions of interest for additional examination were defined in the LM images using the Shuttle & Find software module.

Next, the sample was shifted to a SUPRA 40 VP FE-SEM, which is controlled by the Shuttle & Find software. Following the semi-automatic calibration of the sample-holder and successive fine calibration, the regions of interest in the LM images were relocated within a fraction of seconds at an accuracy of less than 5 Pm. In addition, SEM imaging was performed at 15 kV with the 4 quadrant angular selective backscattered electron detector.

Results

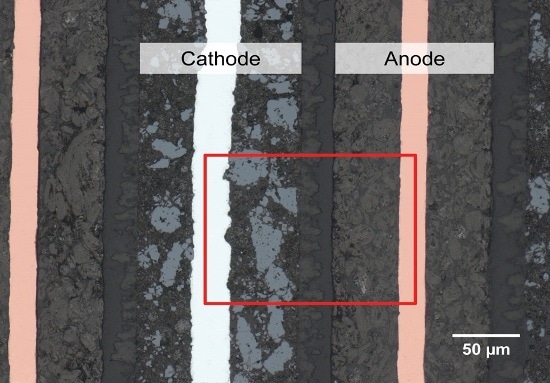

Figure 2. Brightfield LM overview within the layer structure of an aged Li-ion battery

The above figure shows a brightfield LM image of the layer structure inside an aged Li-ion battery. Anode and cathode are layered in alternate fashion, each with a separator in the middle. The anode includes a copper collector with graphite, while the cathode has an aluminum collector covered by lithium metal oxide material. Aging effects can be noted within the separator, wherein a layer grows from the cathode into the separator.

A region of interest, which is indicated by red rectangle in figure 2, is selected that includes an entire unit cell of the battery with aging effects in the separator. The selected region of interest is shown in the below figure.

Figure 3. CLEM of the ROI indicated in Fig. 2 with different contrasts of brightfield (a) and polarized light (b) in LM as well as BSE signal (c) and EDS mapping (d) in SEM

In polarized LM, graphite’s different phase orientations within the anode can be seen, while in the BSE image the grain structures within the cathode material can be observed. This difference allows the division of cathode by utilizing image analysis, so that size and distribution of the grain can be measured. Also, the EDS mapping completes the correlative imaging and offers precise qualitative data on the chemical elements. Lithium cannot be detected in EDS because of physical limitations. However, the roundly shap

ed grains are composed of LiNixCoyO2, while the sharply edged grains inside the cathode active material contained LiMn2O4.

Conclusion

The Shuttle & Find interface allows structural and compositional analysis of aged Li-ion batteries in a fast, accurate and reliable way. The solution also allows new possibilities, particularly for quantitative image data analysis from the same region of interest in different types of microscopes.

This information has been sourced, reviewed and adapted from materials provided by Carl Zeiss Microscopy GmbH.

For more information on this source, please visit Carl Zeiss Microscopy GmbH.