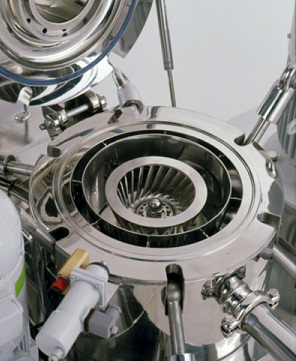

The Mikro ACM air classifier mill, operating in the medium to fine size reduction range, delivers precise particle size due to variable-speed integral air classifier, and attains the smallest amount of ultra fines with a steep particle size distribution. It has been continuously improved and adapted to suit wide range of products, even in processing difficult-to-handle materials.

The Mikro ACM operates on the impact grinding principle. It uses high rotor speeds with a striking edge velocity of up to 120m/s. By striking material particles on the grinding track, fixed liner, or rotating grinding surfaces such as pins or hammers, particle sizes can be reduced. The air classifier mill uses variable classifier speed to precisely control the particle size, cut point, and distribution.

Key Features

The key features of the Mikro ACM air classifier mill are:

- Classifying and grinding in one unit

- Easy to clean and maintain

- Variable speed integral air classifier

- Steep particle size distribution

- Compactly designed to save space

Applications

The applications of the Mikro ACM are in:

- Coatings

- Chemicals

- Minerals

- Confectioneries

- Cosmetics

- Foodstuffs

- Plastics

Specifications

The specifications of the Mikro ACM air classifier mill are:

- Many different sizes available, ranging from 2kW Lab R&D version up to 600kW

- Two special designs include ACM EC (easy clean) with CIP capability and ACM SB (split body), wherein both body sections are allowed to swing open by opening the mill cover, thus providing easy access to internals without any hindrance

- Special designs are available as standard to handle explosion risk products