The electromechanical servo testing actuators are flexible and considered to be ideal for tensile and compression applications. They can be combined into testing devices with different configurations. Application areas range from materials and component testing to the testing of finished end products. These actuators also enable testing in stages of production (for instance, assembling/joining, force fitting and assembly) and are perfect for long-stroke cyclic fatigue strength tests.

Significant Advantages and Features

Description

- Zwick electromechanical servo testing actuators are available in six versions: 1, 2, 5, 10, 20 and 30 kN

- High test speeds up to 30 m/min promise high efficiency

- Operating modes—force control and position control—can be switched effortlessly

- Accessory cards and interfaces are available for effortless integration in production lines

- A wide range of standard modules such as test fixtures, testing software, load cells and testControl standard electronics is available for different testing situations

Advantages and Features

- Flexible usage:

- Flexible programming of test sequences because of versatile interfaces

- Ideally used for clean room areas

- Variable mounting through front or rear flange or via trunion mount

- Measurement and control electronics testControl II in separate casing and therewith optional positionable (Optional in IP54 casing)

- Easy to install and maintain:

- Long lifetime and low maintenance costs

- Installation possible without additional infrastructure (for example, pneumatic connections or hydraulic pumps)

- Wide variety of standard modules:

- Operation through standard PC and testXpert® II software

- Effortless mounting of Zwick load cells and tooling

- Proven digital drive technology controlled by Zwick standard electronics

Applications for Electromechanical Servo Testing Actuators

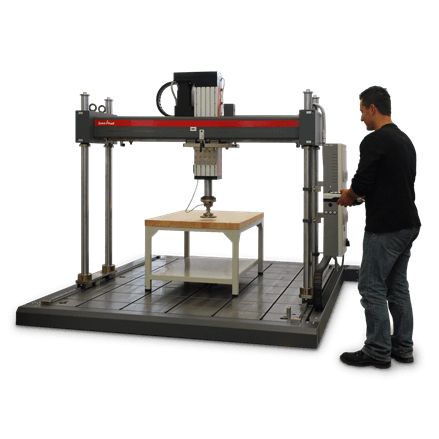

Portal Solutions with Electromechanical Servo Testing Actuators

Testing situations involving huge components such as furniture, wall panels, car seats and vehicle bodywork parts need flexible, large test devices. The portal design of the load frame offers an extensive range of adjustment options and convenient operation. The portals have a modular construction allowing them to be configured effortlessly for testing requirements. The T-slotted basic platform, portal and electromechanical servo testing actuator are all available in different shapes and sizes.

Zwick electromechanical servo testing actuators are available in six versions: 1, 2, 5, 10, 20 and 30 kN and 5 kN or 30 kN portals are selected as appropriate. For the T-slotted base platform, different standard sizes are available besides the availability of special sizes on request. The position of the testing actuator in the X, Y, and Z axes can be manually adjusted or altered through an electric motor.

Different safety cabins are available in agreement with overall size. In most cases, robust, stiff construction allows high measurement accuracy levels without additional measuring transducers.

Other Applications

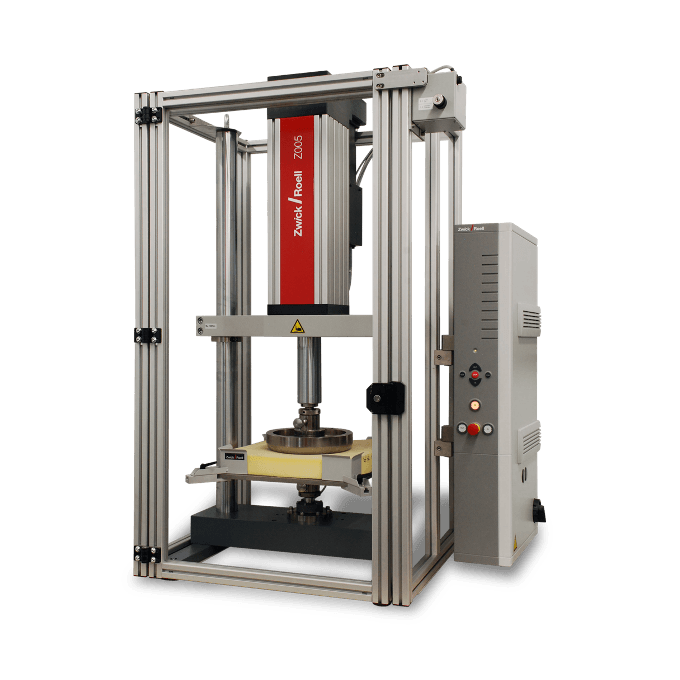

Test Bench for Fatigue Testing of Foams

The test bench for fatigue testing enables indention hardness, material fatigue and compression stress values of flexible foam materials.

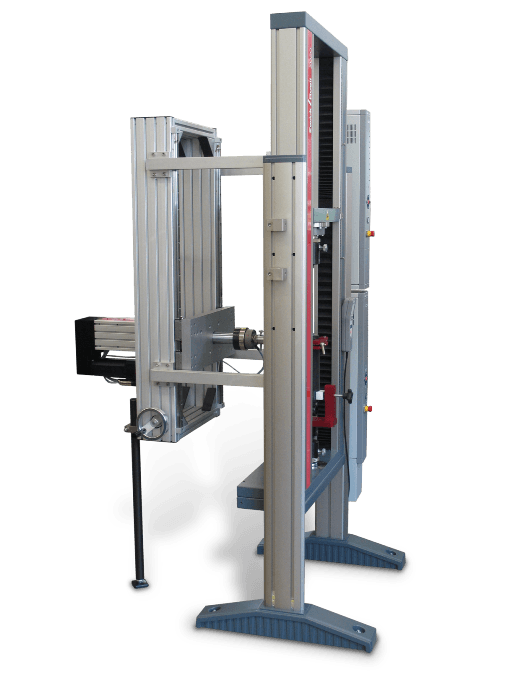

Horizontal Test Axis

Mounting the electromechanical servo testing actuator on a table top testing machine allows side loading of shock absorbers. It is possible to adjust the test height of the actuator.

Integration in a test frame

For compression and tensile applications, the electromechanical servo testing actuator can be integrated with test fixtures in different ways.

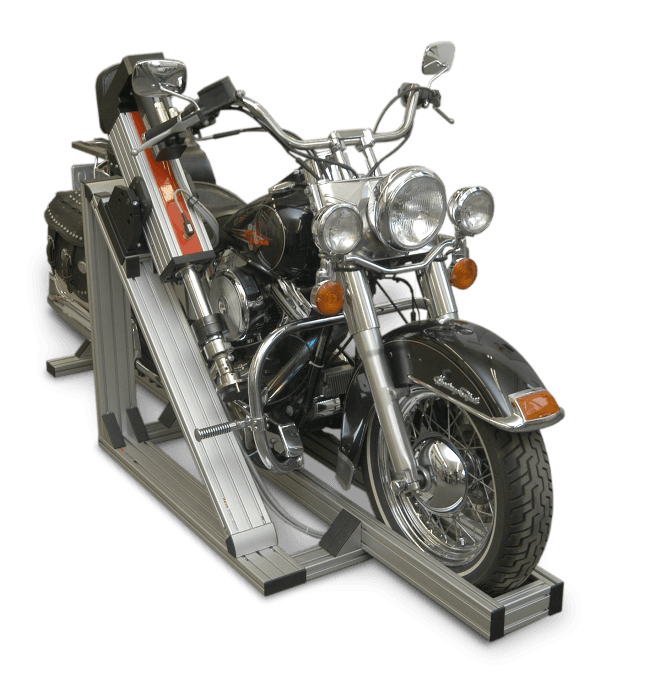

Variable mounting options

The electromechanical servo testing actuator can be used in a variety of ways.