Firwin Corp. has been developing a unique line of insulation products over the last several years in order to meet the strict safety requirements for underground mining.

MineWrap™ Removable Insulation Blankets

MineWrap™ addresses the most important areas of concern related to underground mining:

- Operator burns in confined mine tunnels

- Hard wear conditions of underground mining

- Oil seepage into insulation covers posing probable fire hazard

- Danger of hydraulic oil spills igniting on hot engine surfaces

MineWrap Mark II and Mark III

Increased Fire Safety: Both the Mark II and Mark III are available with a stainless steel foil inner liner. This liner is used for covering the insulation matt in order to prevent oil from a hose burst or an oil leak from reaching the insulation matt material.

MineWrap Mark III

Additional safety and rigidity for demanding underground applications.

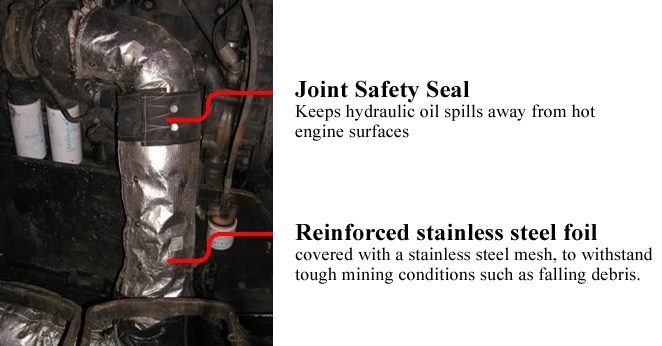

Reinforced Outer Surface: The outer liner is replaced with a reinforced stainless steel foil and mesh by MineWrap™ Mark III. This offers an extra measure of rigidity and also enables the blanket to stand up to the wear and tear of underground mining.

Joint Safety Seal: The Mark III features a Joint Safety Seal for an added measure of safety. Typical engine and exhaust insulation comprise of a number of blanket sections, which are developed in order to overlap one another. Even though these overlaps are designed to fit snugly against one another, there are chances for the oil from a hydraulic hose burst to get in between the blankets and reach hot engine surfaces. The Mark III Joint Safety Seals provide an added measure of fire safety by acting as a barrier to these flammable oils.