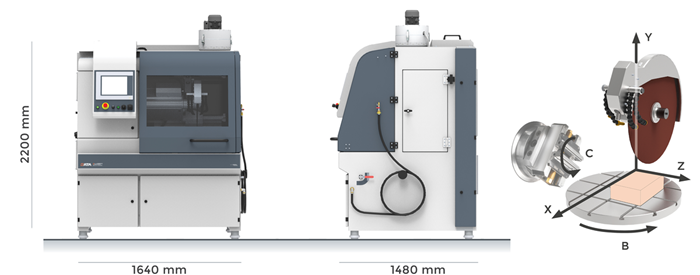

The Qcut 600 BOT is a fully automatic cutting robot with a maximum of 5 axes for the use of cutting discs with a size of up to 610 mm / 24 inches.

The Qcut 600 BOT cutting robot offers new possibilities with its five axes (X, Y, Z, B, C) and a generously sized machine table (Ø 600 mm), opening up new application opportunities. It features automatic travel (X-axis) and cross-cut (Y-axis) speeds of up to 80 mm/second due to its highly dynamic drives.

The rotary table (B-axis) has a swiveling range of 360° and can be extended with an additional rotary axis (C-axis) with a swiveling range of 360°, providing a combined swiveling range of 200° (B-axis) and 360° (C-axis).

During the chop cut, the cut-off wheel guard moves in parallel to increase the cutting capacity of the cut-off wheel. The large sliding and side door, with a safety lock when the cutting disc moves, ensures optimal access to the large machine table.

The machine body of the Qcut 600 BOT is made of robust steel construction and integrates recirculation cooling and automatic central lubrication. Additionally, it can be equipped with a belt filter unit as an alternative to the recirculating cooling unit.

Image Credit: QATM

Product Advantages

- The Qcut 600 BOT offers the highest degree of automation with dynamic cut-off wheel measurement and automatic adjustment of cutting parameters.

- It features visual menu guidance for easy programming.

- Can cut any number of components with different cut-offs in a single process.

- Complex cutting sequences are simplified thanks to the rotation of the machine table, eliminating the need for time-consuming reclamping of workpieces (patented).

- The machine is expandable with an additional rotary axis that can be adapted modularly.

- Offering unlimited clamping possibilities with individually tailored solutions.

- Additionally, the Qcut 600 BOT provides generous access to the cutting chamber.

Image Credit: QATM

Features

Intuitive and Easy Operation

The teach-in function facilitates user-friendly programming of cutting positions by approaching individual positions. The multi-position process (MPP) enables simultaneous positioning and automatic start-up of different components on the clamping table, eliminating the need for time-consuming reclamping.

Image Credit: QATM

Automatic Cut-Off Wheel Measurement

The dynamic cut-off wheel measurement ensures reproducible cutting results with consistent quality. By automatically monitoring the current cut-off wheel diameter, the cutting parameters are adjusted after each cut. This adjustment ensures that the cutting speed and cutting depth remain constant, maintaining consistent and precise cutting performance.

Image Credit: QATM

Cutting Optimization

To optimize cutting quality, the machine automatically detects local material singularities, such as hardened areas, and regulates the feed rate based on the cutting force. Additionally, when starting a new cut, the component is automatically detected and approached at a reduced speed, ensuring a soft start-up control.

Image Credit: QATM

Remote Maintenance

QATM offers direct fault diagnosis and online support, which can be accessed via a VPN connection using an existing broadband internet connection.

Image Credit: QATM

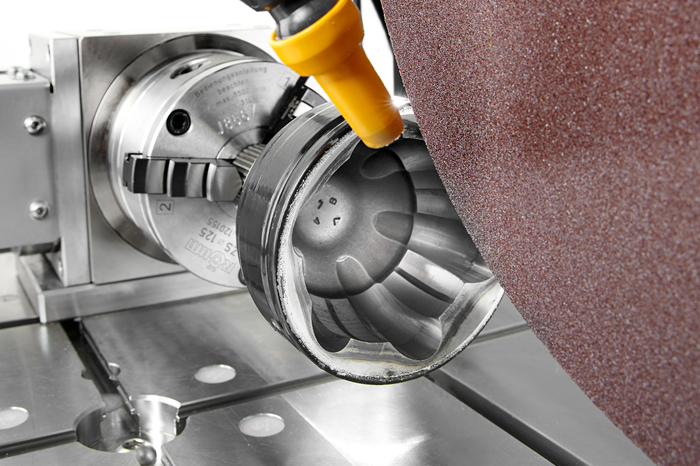

Additional Rotary Axis

Unlimited Clamping Possibilities

The modular C-axis on the table enables precise positioning of complex components, opening up new possibilities in machining. The patented solution of combined rotary axes eliminates the need for time-consuming reclamping and the use of additional clamping tools.

Image Credit: QATM

Cutting Robot Qcut 600 Bot

Cutting Without Restrictions

Image Credit: QATM

- Ergonomic Control Panel

- Large 12.1 inch TFT touch display

- Two joysticks for manual operation

- The sliding display enables clear working

- Optional Axis of Rotation C-axis

- The Qcut 600 BOT offers a maximum rotation range of 360°

- The rotary axis is modularly removable, allowing for easy customization and adaptation

- Clamping possibilities can be individually extended with a lathe chuck or other clamping devices

- Robust Machine Body

- The Qcut 600 BOT is equipped with integrated recirculating cooling and automatic central lubrication

- Large Machine Table

- Axes can be precisely positioned and fixed vibration-free in the cutting process

- Diameter: 600 mm

- Load capacity: 150 kg

- Travel: X/Z-axis: 550 mm

- Side Door

- Swivel door for free access to the cutting chamber

- Change of cutting disc via side door possible

- Automatic Cut-Off Wheel Measurement

- The Qcut 600 BOT offers dynamic adjustment of cutting parameters for optimal results

- Ideal utilization of the cutting space due to innovative transverse infeed via the swivel arm

- Rotational axis

B-axis

- Rotation range 360°

- Rotation range with combined C-axis 200°

- Positioning accuracy: ±0.1°

Free Accessibility

For Large Workpieces

The Qcut 600 BOT features a wide sliding door, allowing large components to be easily placed using a forklift or crane, simplifying loading and unloading operations.

Image Credit: QATM

Cutting Robot Qcut 600 Bot

Technical Data

Machine configurable with 4 (X/Y/Z/B) or 5 axes (X/Y/Z/B/C). Image Credit: QATM

Source: QATM

| . |

. |

| Cutting wheel |

up to ø 610 mm / 24" |

| Max. way of cutting wheel into sample |

244 mm (cutting wheel ø 610 mm) |

| Wheel flange size |

ø 32 / 40 mm |

| X-axis automatic |

550 mm |

| Y-axis automatic |

360 mm |

| Z-axis automatic |

550 mm |

| Precision Z-axis |

0,1 mm |

| B-Axis |

4 axes: 360°

5 axes: 200° |

| C-Axis |

4 axes: -

5 axes: 360° |

| Table |

ø 600 mm, stainless |

| T-slot |

12 mm |

| Speed |

variable 1000 - 2400 rpm |

| Drive power (main drive) |

15 kW, S1 |

| Connection power |

30 kVA |

| W x H x D |

1640 x 2200 x 1480 mm |

| Weight |

approx. 1600 kg (depends on equipment) |