Quality assurance in materialography starts with an excellent cut. For over 20 years, QATM has been at the forefront of innovative precision cutting machines, setting new standards in materialographic sample preparation.

What sets QATM's cutting machines apart is their focus on precision and quality. The Qcut 200, the successor to the Brilliant 220, represents the latest evolution of this popular model in its 4th generation. The Qcut 200 A stands out in the market due to its unique conceptual design as a large cutting machine in a table format.

Product Advantages

- New modular adaptable turning device

- Automatic cleaning function

- Fully automatic precision axes with backlash-free bearings

- Simplified cut-off wheel change

- A new cooling system with an approximate 25% higher flow rate than comparable machines which reduces the cut-off wheel wear by up to 15%

- New software functions for grinding applications

Precision cutting machine Qcut 200 A - QATM

Video Credit: QATM

Precision Cut-Off Machine Qcut 200 A

Features

The Qcut 200 A is a precision cut-off machine with up to 3 automatic axes for use with cut-off wheels up to 203 mm/8'' in size.

The Qcut 200 A is a compact, precision cut-off machine that provides exceptional flexibility and space utilization. It features up to three automatic axes (X, Y, Z) and offers a variety of cutting functions. Its modular design allows for optimal customization with numerous options and compatible clamping tools.

Intuitive and Simple Operation

The large 7" touch display is ergonomically arranged for easy operation using the user-friendly software. The joystick provides comfortable movement of the automatic axes, enhancing the overall user experience.

Image Credit: QATM

Flow Monitoring

With the optional flow monitoring feature, constant cooling can be maintained during cutting processes, ensuring that sensitive samples are protected during long cutting processes. If a critical threshold value is reached, the cutting process is automatically interrupted.

Image Credit: QATM

Highest Demands of Safety

The machine can only be positioned using the two-hand control when the door is open, thanks to the enabling switch. This safety feature eliminates the risk of crushing for the machine operator.

Image Credit: QATM

Intelligent Component Detection

In addition to the established automatic component detection, the machine is equipped with a new type of exit detection (auto-stop function). This feature automatically detects the start and end points of the cutting process, reducing process times.

Image Credit: QATM

Automatic Cleaning Function

The machine features fully automatic cleaning using spiral nozzles in the cutting chamber. Cleaning can be activated individually and can start automatically after each cut-off if desired. Additionally, for a clear view, cleaning can also be activated during the cut-off operation.

Image Credit: QATM

Extensive Cutting Programs

Depending on the component's geometry, either the travel or chop cut is utilized to minimize the contact area between the component and the cut-off wheel. The step cut functions separate the workpiece layer by layer and optimize the angle of action for a material-friendly cut, making them particularly suitable for solid materials.

Image Credit: QATM

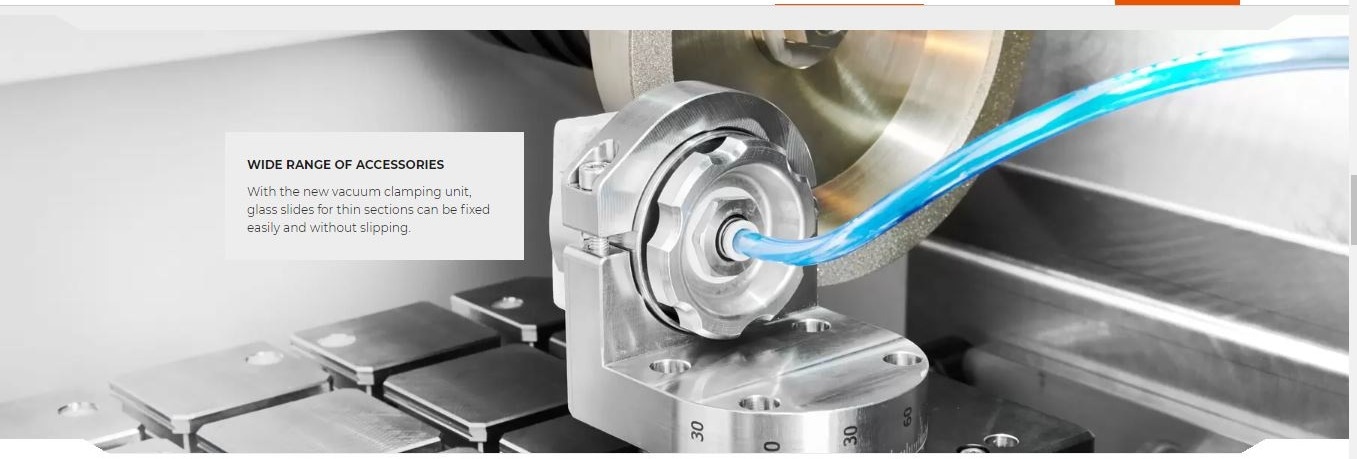

Wide Range of Accessories

The new vacuum clamping unit allows for easy and slip-free fixation of glass slides for thin sections.

Image Credit: QATM

Precision Cut-Off Machine Qcut 200 A

Cutting Without Restrictions

Image Credit: QATM

1. Cutting Chamber Flushing

- The cutting chamber is cleaned automatically

2. Large Machine Table

- The axes can be positioned without backlash

- Easy grooves are provided for simple mounting of QATM clamping devices

- T-slots of 8 mm allow for the use of individual clamping devices

- The maximum dimensions for workpieces are 300 mm width by 210 mm height

3. Ergonomic Control Panel

- Large 7" TFT touch display

- Joystick for manual operation

4. Line Laser

- For exact component part positioning before cutting

- Included as standard

5. Accessories

- The clamping possibility can be individually expanded with a turning device or additional clamping devices

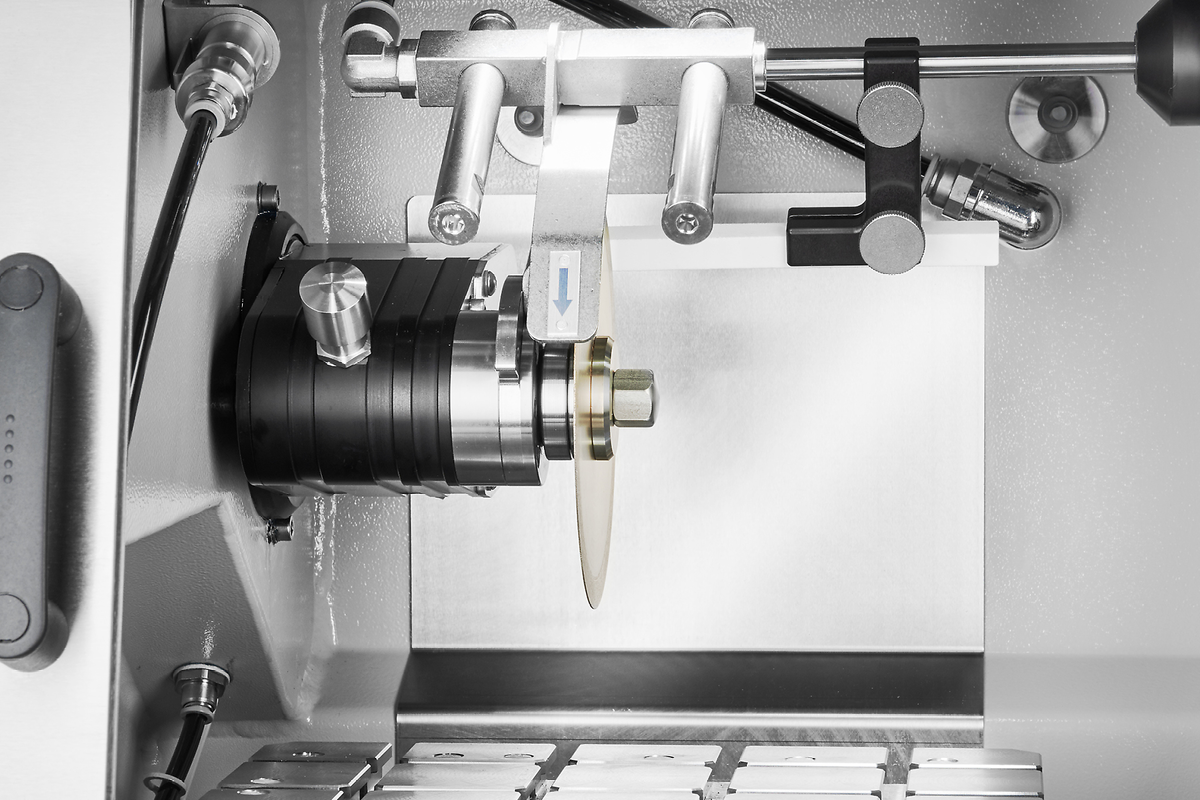

6. Cut-Off Wheel Lock

- Simplified cut-off wheel change via locking function

- With an integrated lubrication option

7. Dressing Device

- For sharpening diamond cutting and grinding wheels

- Can be operated manually from the outside

Accessories

Clamping Tools

A wide range of clamping tools are available with the Qcut 200 A. With the Easy clamping system, these tools can be easily and securely fastened to the table with just one screw, eliminating the need for tedious fixing in the T-slots of the table. The Easy clamping system is an innovative addition that greatly simplifies everyday work.

Easy-clamping base S with rotary function + easy adaption (vertical). Image Credit: QATM

Easy-clamping base S with Qtool 40 S. Image Credit: QATM

Qtool 40. Image Credit: QATM

Precision Cut-Off Machine Qcut 200 A

Technical Data

Image Credit: QATM

Source: QATM

| . |

. |

| Cut-off wheel |

up to Ø 203 mm / 8" |

| Max. cutting capacity |

75 mm (cut-off wheel Ø 200 mm) |

| Wheel flange size |

Ø 12,7 mm |

| X-axis |

210 mm (manual / automatic) |

| Y-axis |

80 mm (automatic) |

| Z-axis (option) |

80 mm (automatic) |

| Precision Z-axis |

0,005 mm |

| min. cross feed (Z-axis) |

0,001 mm |

| Table without Z-axis (WxD) |

300 x 210 mm |

| Table with Z-axis (WxD) |

280 x 210 mm |

| T-slot |

8 mm |

| Speed |

300 - 5000 rpm |

| Drive power (main drive) |

0,75 kW, S1 |

| Connection power |

2,2 kVA |

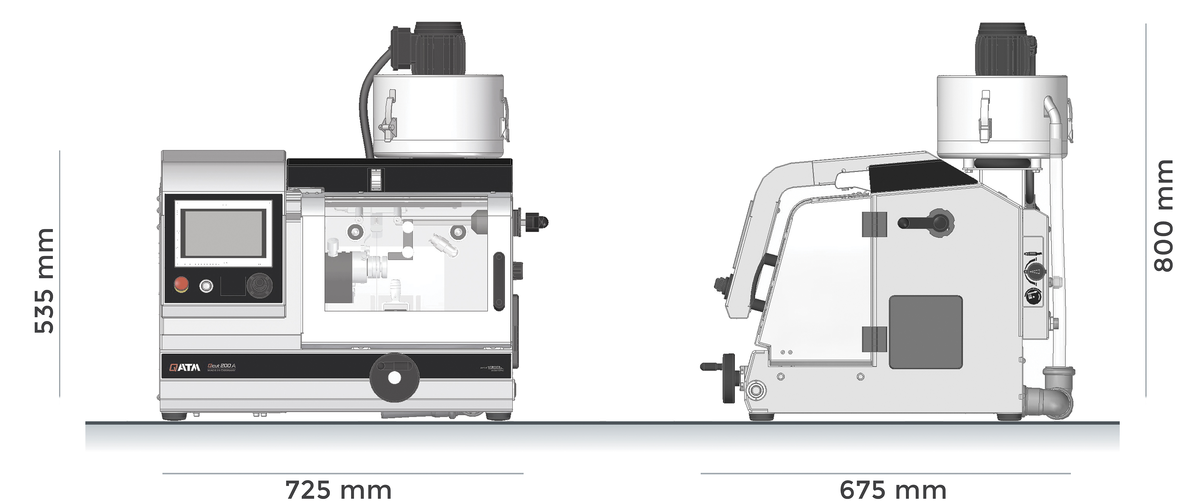

| W x H x D |

725 x 535 x 675 mm |

| Weight |

~ 82 kg |