Better flexibility and varied manufacturing capabilities for both hard and soft machining are two of the main benefits offered by EMAG’s new VL 4 vertical turning machine design. The design of the machine also allows for the easy interlinking of several machines, allowing the line automation to be tailored to fit the customers’ needs. The better flexibility that this vertical lathe allows in the machining of a broad range of chucked components makes it a great option for many diverse manufacturing functions, in several different industries.

Vertical Lathes with a Modular Design for Efficient Production

The VL 4’s modular concept makes it all possible: the vertical turning machine can be fitted to match a range of applications. It is compact in design yet robust and features a combined automation solution with the pick-up spindle. The machine base out of the polymer concrete MINERALIT® guarantees vibration-resistant machining, a prolonged tool life, and exceptional machining quality. The main spindle is mounted on the front compound slide and performs the dynamic movements required in X- and Z-axis with an optional Y-axis.

Technical Data

| Chuck diameter, max. |

mm

in |

260

10 |

| Workpiece diameter, max. |

mm

in |

200

8 |

| Workpiece length, max. |

mm

in |

200

8 |

| X-axis travel |

mm

in |

740

29 |

| Z-axis travel |

mm

in |

400

15.5 |

| Y-axis travel (optional) |

mm

in |

± 30

± 1 |

| Main spindle: Power rating at 40 % / 100 % duty cycle |

kW

hp |

25 / 18

33.5 / 24 |

| Main spindle: Torque at 40 % / 100 % duty cycle |

Nm

ft-lb |

280 / 202

206.5 / 149 |

| Main spindle: Speed, max. |

1/min

rpm |

4,500

4,500 |

| Turret tool stations, Qty |

|

12 |

| Rapid-traverse rate X / Y / Z |

m/min |

60 / 15 / 30 |

| Speed driven tools |

1/min

rpm |

6,000

6,000 |

| Torque driven tools, 30% / 100% |

Nm

ft-lb |

27 / 15

20 / 11 |

Advantages

- Self-loading machine with a pick-up spindle and combined conveyor belt

- Tool turret with 12 tool positions (also for driven tools) and extremely short indexing times

- MINERALIT® polymer concrete machine base guarantees high stability and exceptional vibration damping

- The machines can be fitted with a Y-axis in the turret to allow for the machining of intricate geometries

- Vertical machining offers ideal downward chip flow conditions

- All service units are freely accessible and thus easy to reach

Workpieces / Technologies

Workpieces

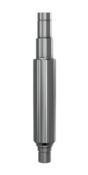

Rotor shaft (electric motor)

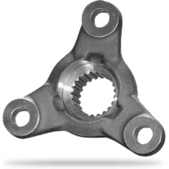

Triple-sector clutch

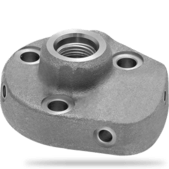

Distributor flange

Flange

Technologies

Induction hardening

Vertical turning

Vertical Turning Machine for Chucked Components – VL 4