LECO's Glow Discharge Spectrometer (GDS) provides state-of-the-art technology intended specifically for routine elemental determination in the majority of conductive ferrous and nonferrous materials. The GDS900 boasts improved performance, stability, accuracy, and precision in steel, iron (including as-cast), aluminum, copper, zinc, nickel, cobalt, tungsten, and titanium materials, while including our user-friendly Cornerstone brand software to help streamline analysis.

LECO’s exclusive software with touch-screen interface allows access to analysis control, method settings, diagnostics, reporting, and more in a highly ordered, instinctive, immersive setting. Our grouping of sample data into sets and replicates streamlines data output and automatically computes relevant statistics.

Optional nitrogen recirculation can lower nitrogen consumption by more than 1200% annually, reduce cost-per-analysis by almost 58%, and improve overall system stability and increase uptime

Feature Highlights

Glow Discharge Source Advantages

- Simple, linear calibrations compared to other sources

- Controlled excitation away from the sample surface

- Reduced reference material consumption

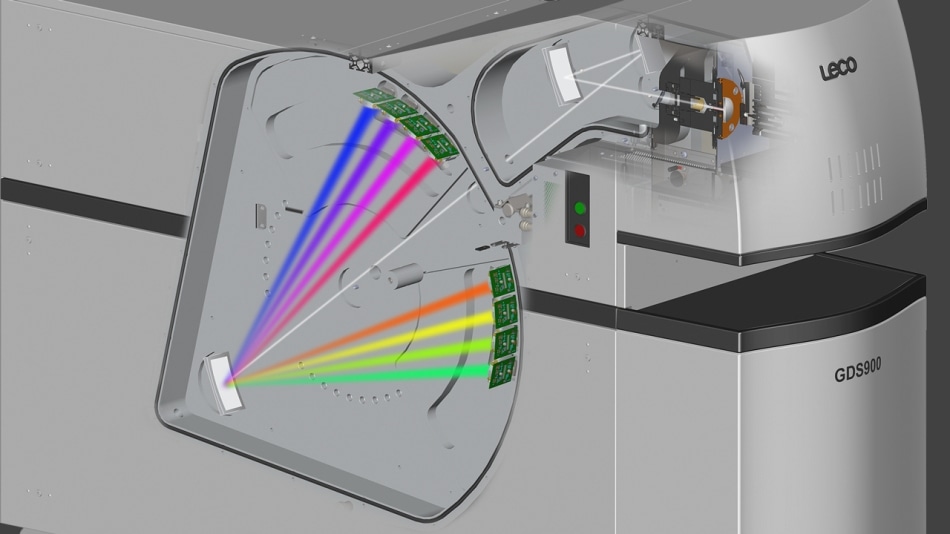

Detection System Advantages

- The integral sensitivity, dynamic range and linearity of CCD detectors combined with the GD source ensures steadiness, flexibility, and performance for all bulk elemental applications

- Full wavelength coverage from 160 nm to 460 nm

- 50 pm (0.050 nm) resolution to distinguish even the most complex features of bulk spectra

System Level User Advantages

- Easy to operate, maintain, and service

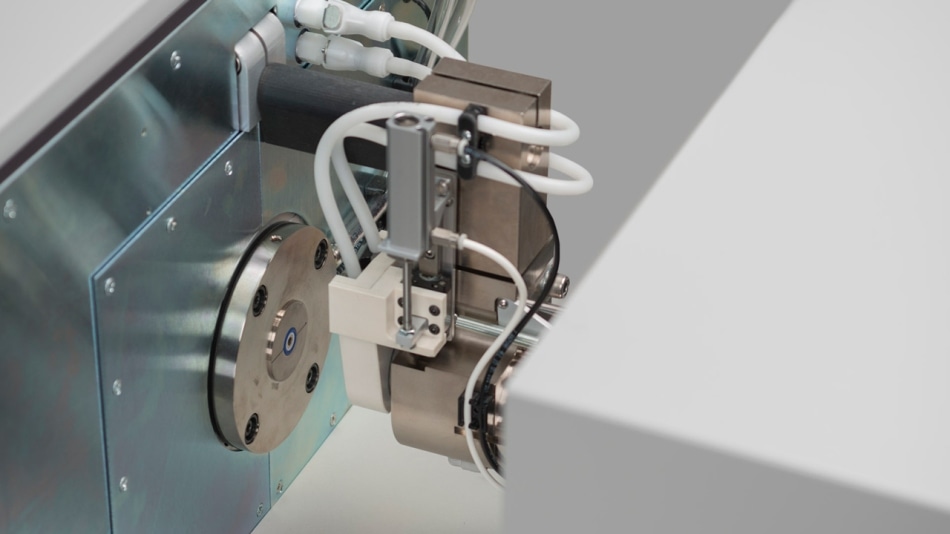

- Automatic cleaning between samples saves time, minimizes matrix effects for greater precision

- Open lamp design and ambidextrous controls allow both right and left-hand operation