H.C. Starck Soutions' range supports the LED market with products essential to the success of the sapphire crystal-growing industry’s high-temperature furnaces. There is significant growth in the production of these customized, high-temperature vacuum or argon atmosphere furnaces for growing sapphire crystals used in the manufacture of LEDs. These furnaces have exceptional and challenging hot zone designs for melting alumina in crucibles for precise, extremely controlled crystal growth.

Whether by EFG, KY, CZ, or HEM-like (CHES, GTAT, and VHGF), H.C. Starck Soutions has the expertise in these various sapphire crystal growth techniques and supplies engineered product solutions for all technology systems.

The hot zones in sapphire growing furnaces use H.C. Starck Solutions' tungsten and molybdenum products for furnace parts and fixtures. These high-temperature materials are characterized by their low coefficient of thermal expansion, high thermal and electrical conductivity, and outstanding strength and stability at temperatures over 2,000 °C.

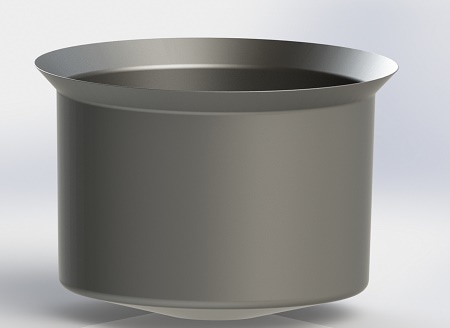

Customized furnace components and fixtures for high-temperature furnaces are exclusively designed and supplied by H.C. Starck Soutions. Machined and fabricated products from tungsten and molybdenum sheet, plate, and foil include:

- Heating element materials

- Seed holders

- Heat shields

- Other support components