H.C. Starck Soutions offers value-added product solutions for various difficult applications like annealing of medical and aerospace products to essential specifications, heat treatment of large aerospace components in vacuum furnaces, and brazing of high production components in controlled-atmosphere furnaces.

H.C. Starck Soutions Products for Heat Treating and Furnace Markets

H.C. Starck Soutions produces products made of tungsten, tantalum, molybdenum, and alloys like TZM and lanthanum oxide dispersion strengthened (ODS) molybdenum for application in the heat treating and furnace markets. These materials exhibit optimal mechanical durability, low coefficient of thermal expansion, unmatched stability and strength, and high thermal and electrical conductivity at higher temperatures of 2000 °C.

H.C. Starck Soutions provides product solutions for all high-temperature furnace applications, including brazing, annealing, sintering and vacuum heat treating, in a variety of industries such as automotive, defense, aerospace, and medical. H.C. Starck Soutions provides the following product solutions:

- Heating element materials

- Tantalum hot zones and furnace hardware

- Vacuum furnace materials

- Molybdenum and tungsten mill products

- Heat shields

- Hot zone replacement parts

- Furnace parts

High-Temperature Furnace Applications

H.C. Starck Soutions manufactures molybdenum and tungsten materials for application in high-temperature argon and vacuum atmosphere furnaces. It provides services such as pre-characterization of materials, for example, evaluating material performance after being subject to high-temperature annealing.

Lab Testing Furnaces

- High-temperature capabilities in reduced, vacuum, and inert atmospheres

- Chemical reactions furnaces (vacuum, air, or other atmospheres)

- Controlled-atmosphere furnace applications

Medical - Orthopedic and joint replacements

Furnace - Heating elements and heat shields

Aerospace - Rocket nozzles

Energy - Carbide drilling equipment

Sapphire crystal growth furnaces include distinctively designed hot zones for holding crucibles, which melt alumina for high-quality substrates applied for producing LEDs.

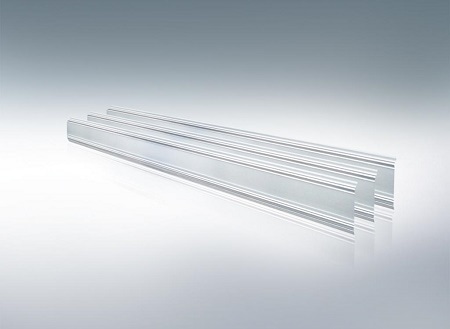

Molybdenum Furnace Parts

H.C. Starck Soutions uses two main consolidation methods for producing different molybdenum and molybdenum alloy mill products. These techniques include powder metallurgy (PM) and vacuum arc-casting (AC). Product availability from both these established processes provides users a variety of options in choosing a material to meet their specific application needs. Mill products available from either of these processes include forging billets, rod, bar, plate, foil, and sheet.