ATHENA is the latest atomic layer deposition (ALD) tool from Forge Nano, developed mainly for coating 3D and high surface area objects. ATHENA is the most versatile, economical, and user-friendly commercial ALD objects research tool.

Forge Nano’s ATHENA has been designed for:

- Research and development—Multiple chemistries on numerous objects for various research projects

- Objects coating—Particularly for 3D and highly porous objects

- Low particle environments—Clean hood integration option to facilitate particle-sensitive applications

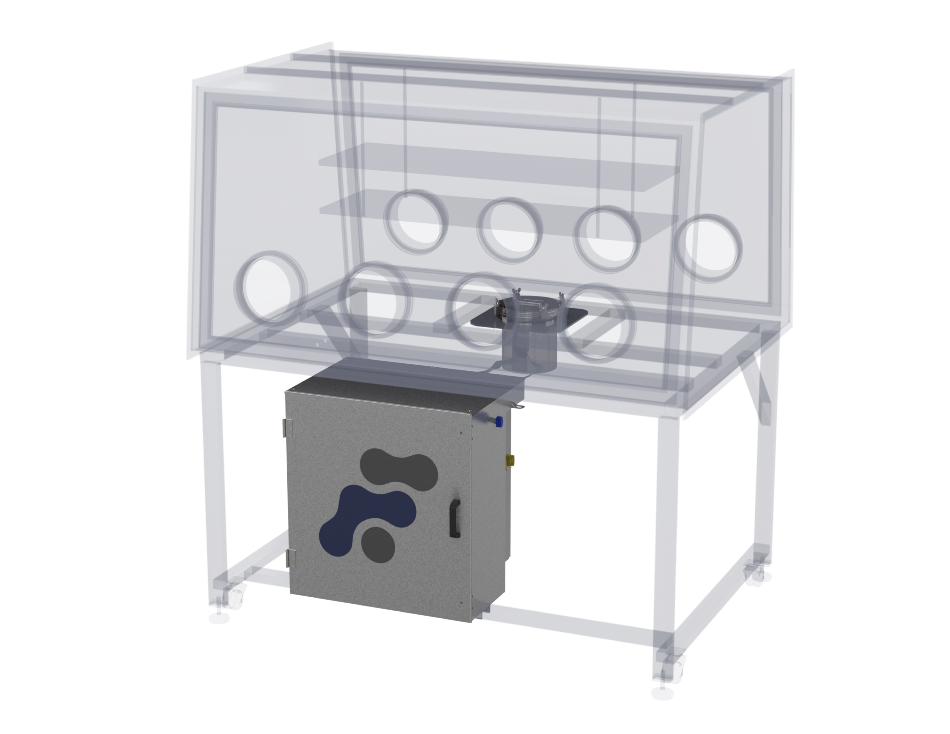

- Air-sensitive material—Optional glovebox integration enables inert handling of materials

The innovative design of ATHENA offers the reliability and versatility that research projects need. The tool has the ability to evenly coat objects of different sizes and shapes, and inside pores. Users can achieve results in no time.

Forge Nano’s custom tooling enables users to coat many objects at the same time, maximizing the system space and reducing coating time by multiplexing substrates.

Technical Specifications

The ATHENA series of systems are all provided with:

- Ergonomic doors for easy access to manifold components, precursor bottles, heating, and other components

- Automated dosing system for minimum chemical waste and ultimate uniformity

- User-friendly, recipe-based control software for quick execution of experiments

Optional Glovebox Integration

Forge Nano has collaborated with MBRAUN to deliver the latest in air-sensitive ALD technology. Forge Nano’s integrated glovebox systems enable users to work free of CO2, O2, and moisture, allowing them to concentrate more on creating new materials.