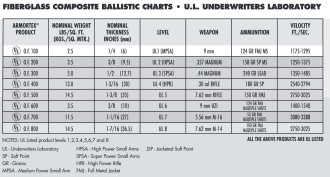

The bullet-resistant fiberglass panels available from Armortex® offer complete reliability in high-performance ballistics applications. The panels have been designed to resist very high impact forces in accordance with Underwriters Laboratories (UL) 752 standards 1 to 8.

Armortex’s customers determine the measure of safety they need, and the company offers bullet-resistant fiberglass panels to suit their special requirements.

All the bullet-resistant fiberglass panels from Armortex are manufactured in-house, using a roving ballistic-grade fiberglass. Thermoset resin is mechanically injected into this cloth, which is pressed into flat rigid sheets with the help of a hydraulic hot press.

Through this process, Amortex optimizes the ballistic performance of its fiberglass panels, by means of accurate de-lamination and reliable projectile retention.

Bullet-Resistant Fiberglass Panels from Armortex

Armortex® prides itself on developing physical security solutions with a customer-centric mindset. All the bullet-resistant fiberglass panels from the company are UL-compliant and are used by the U.S. Marshal Service and the General Services Administration, as well as various other government agencies.

Key Statistics

- Ballistic level (UL) of 1 to 8

- Width of 3 or 4 feet

- Length of 8, 9, or 10 feet

- Nominal thickness of ¼, ⅜, ½, 1 3/16, 1⅜, ⅜, 1 1/16, or 1 7/16 inches

- Nominal weight of 2.5 to 14.5 pound per square foot

- Edge—Square

- Application—Interior unless coated with polyurea for exterior applications

- Primary material—Composite fiberglass

Image Credit: Armortex

Image Credit: Armortex