The Thermo Scientific™ ARL™ SMS-3300 is a comprehensive answer to laboratory workflow automation, meticulously crafted to elevate productivity within process control laboratories across mining, cement, and metals industries. With its adept handling of multiple spectrometer automation, it presents users with expanded horizons, catering to those seeking comprehensive and seamless automation solutions.

Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

An Evolution of Existing Automation Solutions

Since the early 1990s, Thermo Scientific has continuously refined its robotic spectrometers, drawing insights from customer feedback and real-world experiences. With over 1000 systems deployed globally across the metals, cement, and mining sectors, Thermo Scientific maintains a sterling reputation for reliability and performance, reflecting its unwavering commitment to excellence.

Building on this achievement, the ARL SMS-3300 system demonstrates:

- The commitment to prioritize holistic workflow solutions over merely the physical footprint of individual laboratory equipment.

- Leveraging diverse competencies and products, including larger and more powerful robots, to deliver cutting-edge automation solutions at the forefront of technology.

- The goal is to provide customers “in-the-field” simply upgradeable systems that can go from single to dual instruments with the least effort and expense and the least environmental impact

Single Source – One Partner, One Competence, One Responsibility

Thermo Scientific is at the forefront of innovation in designing and manufacturing X-Ray fluorescence (XRF) and optical emission spectrometers (OES) integrated with cutting-edge automation systems.

The expertise extends to complete systems provided as turnkey packages, including sample preparation, rather than limited to a single automation or analytical approach.

Exceptional Performance at Affordable Cost

Single Instrument Configuration: ARL SMS-3300 Single

This is particularly beneficial for customers anticipating future growth in their analytical needs. The ARL SMS-3300 Single can be easily upgraded in the field to the ARL SMS-3300 Dual system.

Double OES Configuration: ARL SMS-3300 Dual

This scenario is common in laboratories used by primary metal producers, where the permanent availability of two instruments ensures continuous analytical services and swift response times, especially when handling multiple urgent samples simultaneously.

High Sample Throughput and Analysis Dependability

This capability allows for managing substantial sample workloads in metal applications. The ARL SMS-3300 system offers a cost-effective alternative to the expense of two wholly duplicated and separate automated lines, each equipped with its own robot. It streamlines sample handling by consolidating all samples to a single introduction point and optionally providing magazine storage for up to 32 production samples to facilitate introduction.

Combined XRF and OES Analysis

For high-alloy and stainless steel, aluminum, copper, brass, and bronze applications, the ARL 9900 XRF spectrometer provides high-concentration alloy elements, while the ARL iSpark metals analyzer provides trace and light elements.

Very Short Response Times

The ARL SMS-3300 robot quickly moves samples between system components.

Increased Uptime and Speed

Eliminating time-consuming and complex electromechanical transfer systems significantly boosts the speed of delivering findings, enhancing manufacturing turnover. This speed is more significant than productivity improvements related to labor savings.

Latest Industrial Robotics Technology with Intelligent ARL SMS Software

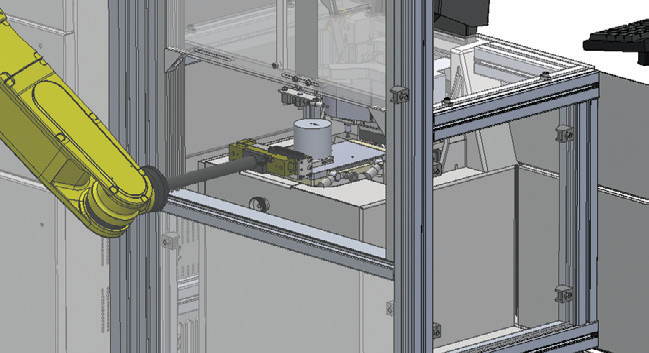

The ARL SMS-3300 system seamlessly operates two spectrometers and one preparation machine simultaneously, leveraging SMS software enhanced with intelligence. It incorporates a FANUC robot, recognized as the leading provider of industrial robots worldwide.

The ARL SMS-3300 system employs a medium pedestal standing industrial robot with a 1320 mm arm length, a gripper, and six moving axes. Its larger work volume facilitates the installation of two spectrometers side by side.

Despite requiring minimal floor space for the entire system, short distances between components ensure rapid operation without sacrificing accessibility for service and maintenance. This setup also enhances flexibility in positioning and interfacing the sample preparation machine.

The ARL SMS-3300 heavy-duty robot boasts an impressive maximum payload of 7 kg, ideal for automating twin spectrometers. This payload capacity is well-suited for typical production sample weights, reduces stress and wear, enhances reliability, and extends lifespan. Thanks to the utilization of high-precision, brushless AC-Servo motors, and internal cabling, the ARL SMS-3300 robot demands minimal maintenance.

Its absolute encoder technology establishes the mechanical origin permanently upon initial startup, ensuring precision throughout its operational lifetime.

ARL SMS-3300 with single or dual OES instrument configuration. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

ARL iSpark AutoStand. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

An Automation Product Designed with Users in Mind

Simplicity of Operation

The ARL SMS-3300 automation software operates on the same platform as the OXSAS analytical software for OES and XRF spectrometers. This standardized software environment simplifies the use of fully automated OES and XRF spectrometers. Furthermore, a single SMS system monitoring screen provides comprehensive sample tracking and automation capabilities.

Flexible Instrument Integration and Comprehensive Analysis Modes

Employing two equivalent spectrometers enables simultaneous sample analysis, optimizing throughput and minimizing response times. Samples can be prepared by a machine and analyzed by either spectrometer, ensuring round-the-clock availability.

Sequential processing is used with twin XRF and OES systems to measure the same sample. Each spectrometer can be utilized offline for testing and developing analytical methods. The SMS software automatically controls the operator and robot’s instrument accesses; an easy software command allows equipment to be switched between automated and manual modes.

Full Compliance with Security Regulations

The appropriate CE compliance standards were followed in the ARL SMS-3300 safety enclosure design. The system complies with electromagnetic rules and guidelines and robotics applications.

A separate control box pauses robot action and unlocks access doors for manual intervention within the system. Automatic operations can be easily resumed without restarting the system.

Easy Service and Maintenance

The instruments and preparation machines can be swiftly detached without interrupting the automatic system operation. Furthermore, the spectrometers can be relocated to a designated park position for service or manual operation, eliminating the need to halt the SMS system or disconnect spectrometer supplies. Resuming automated operation and repositioning the spectrometer into the SMS requires just a few minutes.

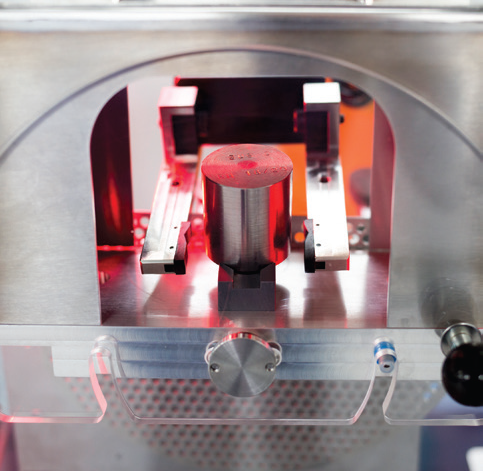

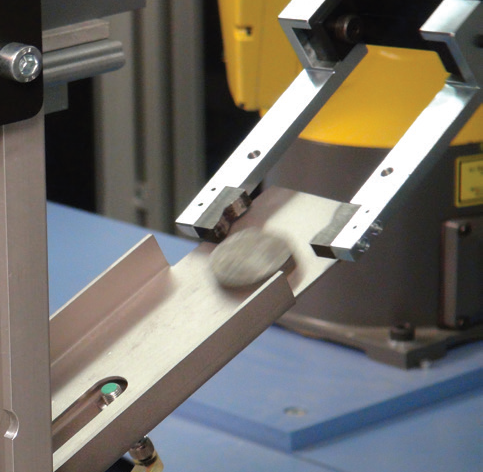

ARL iSpark robot access for automatic analysis. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

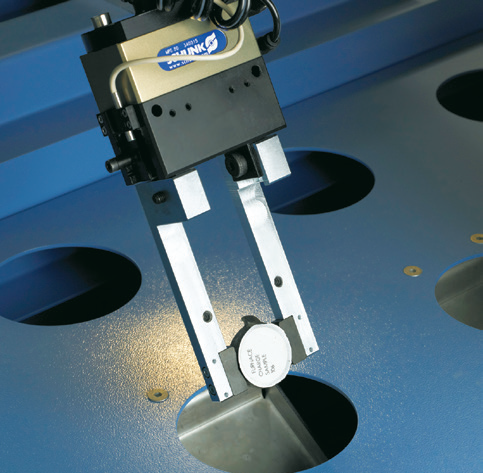

ARL iSpark access for manual analysis. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

SCT Samples Magazine. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

Material Analysis is the Job, Quality the Strength, and Automation the Commitment

The ARL SMS-3300 System Features as Standard

- Support for conditioning samples for cleaning the OES stand

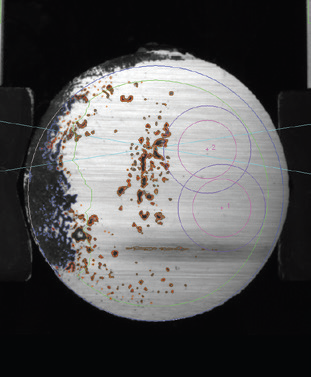

- To prevent surface bias over time, the robot rotates standards before re-preparation

- Filing of selected samples on a chute (e.g. bad samples)

- Sample sorting and filing in 8 boxes

- An inverting device turns standards and samples upside down during or after preparation.

- The manual introduction job involves introducing/removing standards from the system and introducing production samples.

- The safety enclosure has computer-controlled operator access doors and a control box.

- Color lamps display the condition of the system and instruments

- Thorough instrument monitoring protocols to guarantee that the spectrometers consistently produce high-quality findings, preventing waste and rework in production

- Prompt identification of sample presence

- Waiting positions are used to temporarily store prepared samples before analysis to enhance throughput.

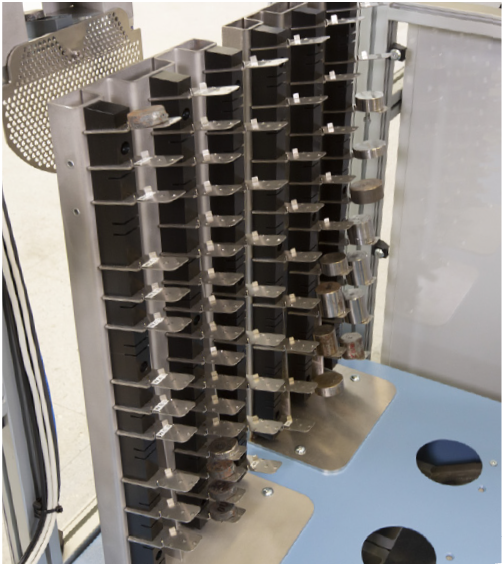

- A large magazine can hold up to 153 setting-up, control samples, and type standards and can be shared between two spectrometers or devoted to one instrument. Magazine sections can be used to temporarily store incoming samples.

Fixed magazine for standards. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

Manual introduction position. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

Production or SCT Sample filing in a box. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

Production or SCT Sample filing on a chute. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

Scalable Solution to Meet Specific Needs

Easy In-Field Upgradability from Single to Dual Instrument Automatic System

A full range of options, which include:

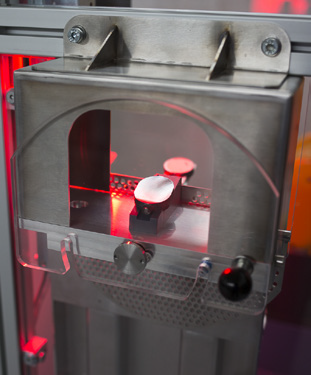

- A vision system evaluates the surface quality of prepared samples and rejects them without further investigation. Selecting optimal spark positions for challenging samples using OES

- Sample batches and collections to make it easier to register and process recurring series of samples (such as samples from electrolytic baths with aluminum)

- Remote control of the automated ARL OES and XRF spectrometers

- Extra digital signals beyond the ones included in the standard allow alarms to be communicated to external visual or acoustic devices.

- Automatically re-prepare samples that cannot be examined

- Production samples are filed chronologically on three chutes in addition to the one supplied as standard

- Sample radioactivity detection (RMS)

- Local or remote manual sample introduction door

- Handling and cooling of hot samples (Max. 850 °C) using air and/or water media

- With SMS Scheduler, control, and standardization, sample analysis can be done automatically at predefined times and intervals

- Integrated bar-code reader for automatic sample registration, reducing the possibility of mistake mistakes while manually inputting sample data before analysis and enabling quicker sample identification

- The sample introduction magazine can handle up to 32 manufacturing samples based on priority.

- Selecting a suitable sample preparation machine is crucial for producing high-quality, reproducible analysis surfaces.

- Support for oxides used in metal manufacturing, including mineral ores, sinters, baths, slags, and blast furnace slags

- Up to 5 production sample shapes

- Sample registration via terminal or network

- Registration with sample identifying parameters captured on a network disk

- Label manufacturing samples on the analytical surface or back

- Dot-peen printer to mark “soft” samples

Vision system. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

Manual sample introduction door. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

Spark position evaluation with vision system. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

Labeling system. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

SMS Cooling. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis

Temporary storage of incoming samples. Image Credit: Thermo Fisher Scientific - Elemental and Phase Analysis