One of the more reliable techniques for determining how much gold, silver, and other Platinum Group Metals are present in different materials (such as ores and slurries) is fire assay analysis. It is appropriate for the most rigorous analytical purposes, from exploration to metal accounting, and from recycling to mining.

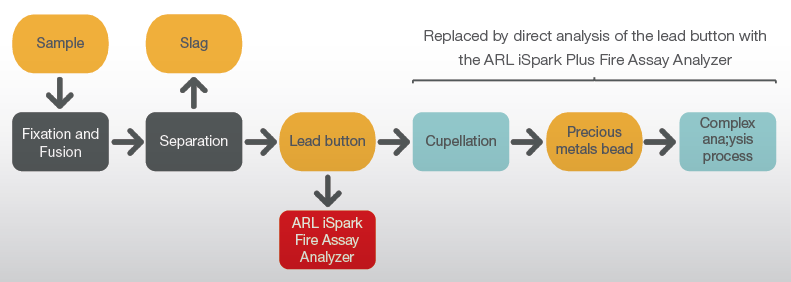

The steps involved in a traditional fire assay analysis are as follows

- Fusion and fluxing

- Slag separation from the lead button

- Cupellation—forming the precious metal bead

- Complex analysis procedure

While offering precise findings at extremely low precious metal concentrations, conventional fire assay analysis has significant disadvantages, such as expense, time, and risk for both the environment and the operator.

These limitations are reduced when cupellation and subsequent analysis are replaced by the direct determination of the precious metal contents in the lead button using the ARL iSpark Plus Fire Assay Analyzer.

ARL iSpark Plus Fire Assay Analyzer. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

ARL iSpark Plus Fire Assay Analyzer

With a focus on fire assay lead button analysis, Thermo Scientific TM ARLTM iSpark Plus Fire Assay Analyzer is a spark optical emission spectrometer with exceptional performance.

As a result of its 1 m focal length optics with photomultiplier tubes and cutting-edge technology, it has the limits of detection necessary for the optimal quantification of the trace level contents of platinum, gold, and silver trace elements in lead buttons.

Traditional Fire Assay Analysis and Alternative with ARL Ispark Plus Fire Assay Analyzer

Image Credit: Thermo Scientific - Chemical Analysis - Production Process and Analytics

Traditional Fire Assay Process

The steps involved in a typical fire assay analysis are as follows:

- Fluxing and Fusion: The sample is pulverized, combined with lead oxide and flux, then heated to approximately 1100 °C in a crucible. The lead oxide is reduced to liquid lead and quantitatively absorbs the precious metals.

- Separation: A mold is filled with the molten mixture. While the slag hardens on the surface, the lead descends to the bottom of the mold and solidifies into a lead button. The slag is extracted with great care.

- Cupellation: A lead button is placed into a crucible (the cupel), and heated to approximately 1000 °C. When lead comes into touch with air, it oxidizes and becomes absorbed by the cupel, leaving behind a precious metal bead.

- Analysis Process: After dissolving the precious metal bead in aqua regia, the contents of the precious metal are measured using gravimetric or instrumental techniques, most often AAS, ICP-AES, and ICP-MS.

The Alternative with ARL iSpark Plus Fire Assay Analyzer

Using the ARL iSpark Plus Fire Assay Analyzer, a straightforward analysis of the lead button takes the place of cupellation and complicated analysis procedures.

Benefits

Every concentration of precious metal accessible in a minute

- No risk to the environment from the disposal of lead-contaminated cups

- Lower risks for operators exposed to heat and toxic substances, dust, and fumes

- Only one analytical instrument, meaning low investment and operating costs

- Seamless automation of the analysis with ARL SMS (Sample Manipulation Systems)