The new Mixer Mill MM 500 Vario from RETSCH is a multi-purpose bench-top unit that offers complete performance with maximum flexibility for the sample preparation process.

This instrument can be employed for wet, dry and cryogenic grinding of small sample amounts with high throughput. The MM 500 Vario can be fitted with screw-top grinding jars from 1.5 to 50 mL. The materials available include stainless steel, hardened steel, agate, tungsten carbide, zirconium oxide and PTFE.

The MM 500 Vario can be fitted with various adapters for single-use vials from 0.2 to 5 mL for biological applications like the homogenization of tissues, plant materials or for cell disruption through bead beating.

Mixer Mill MM 500 Vario #RETSCH #mixermill #laboratoryinstruments

Product Video. Video Credit: RETSCH GmbH

Performance and Design

- Possible to grind sizes down to 5 μm

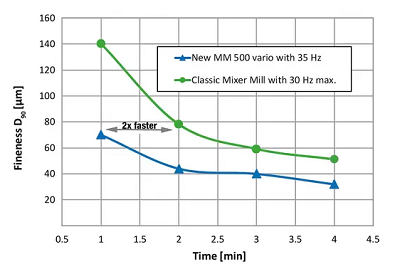

- Twice as fast as mills with only 30 Hz

- Robust pulverization with up to 35 Hz

- Ergonomic design with touch display

Flexibility

- Appropriate for wet, dry or cryogenic grinding

- 12 SOPs and four program cycles with a maximum of 99 repeats enables routine applications

- Also appropriate for quick (<2 min) and long-term grinding (up to 99 hours)

- Grinding jars of different sizes and materials; adapters for single-use vials

Image Credit: RETSCH GmbH

Solutions for Biological Applications and Cell Disruption

Mixer mills are broadly employed for homogenizing biological samples like liver, tissue, muscle, plants, corn or sputum. Bead beating mixer mills are the perfect solution for cell disruption. The MM 500 Vario harbors adapters for various single-use vials like 0.2 mL/1.5 mL/2 mL/5 mL.

Around 5–10 tubes can be introduced per adapter based on the tube and the type of adapter. This results in the maximum vial capacity per batch as follows:

- 50 x 1.5 or 2 mL (or 60 x 0.2 mL)

- 20 x 5 mL

Typical grinding/homogenizing processes of biological materials require no more than 2 minutes. Cell disruption with better reproducibility and efficacy can be achieved in 20 seconds to 5 minutes, based on the cell type. Cryogenic grinding in single-use vials is also a better means to pulverize tough or temperature-sensitive samples.

Solutions for biological applications and cell disruption. Image Credit: RETSCH GmbH

Maximizing Throughput

- In combination, the throughput of the MM 500 Vario is six times greater compared to a conventional mixer mill

- The maximum frequency of 35 Hz decreases grinding time to 50% when compared to mixer mills with only 30 Hz

- Has six grinding stations in place of two, as in classic mixer mills, assuring high throughput

Grinding of basalt in the MM 500 Vario results in better fineness compared to classic Mixer Mills thanks to the increased frequency of 35 Hz instead of 30 Hz (50 mL jar + 12 x 12 mm grinding balls). Image Credit: RETSCH GmbH

Accessories for the MM 500 Vario

Grinding Jars in Six Different Materials

Grinding jars of the earlier MM 400 model are suitable for the MM 500 Vario, even though they are comparatively smaller. The nominal volume ranges from 1.5 to 50 mL and materials available are stainless steel, hardened steel, tungsten carbide, agate, zirconium oxide and PTFE, assuring contamination-free sample preparation.

Image Credit: RETSCH GmbH

Adapters for Single-Use Vials

The adapters for 0.5/1.5/2/5 mL single-use vials of the MM 400 model, which is smaller, can be also used in the MM 500 Vario.

Image Credit: RETSCH GmbH

Typical Sample Materials

Mixer mills from RETSCH are true all-rounders. They homogenize, for instance, soil, waste, coated tablets, chemical products, drugs, ores, tissue, grain, hair, glass, ceramics, bones, alloys, plastics, oilseeds, plants, minerals, sewage sludge, textiles, pills, wool, etc.

Concrete. Image Credit: RETSCH GmbH

Wood. Image Credit: RETSCH GmbH

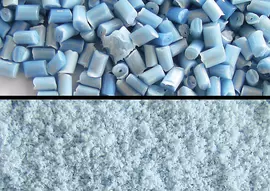

Plastic granulates. Image Credit: RETSCH GmbH

Hair. Image Credit: RETSCH GmbH

Functional Principle

The grinding jars of the Mixer Mill MM 500 Vario carry out radial oscillations in a horizontal position. The inertia of the grinding balls puts forth high energy on the sample material at the rounded ends of the grinding jars and pulverizes it.

The movement of the grinding jars along with the movement of the balls brings about the intensive mixing of the sample. The degree of mixing can be enhanced by employing numerous smaller balls.

videoanimation mixer mill function 480x360

Video Credit: RETSCH GmbH