The 960-TX from Columbia has been particularly developed to track vibration produced by commercial and military helicopter engines, transmissions and airfames. The 960-TX consists of three miniature vibration sensors that are mutually perpendicular and embedded into a tough machined housing integrating a single central mounting screw

The 960-TX features combined thick film electronic signal conditioning circuitry which offers temperature compensation, low impedance output drive capability and high sensitivity.

The sensor configuration is suited perfectly to other vibration monitoring applications like structural analysis and aircraft modal, commercial machinery vibration monitoring, and as the key vibration sensor for all prognostic maintenance vibration diagnostic systems.

- Engine, transmission and airframe vibration measurement

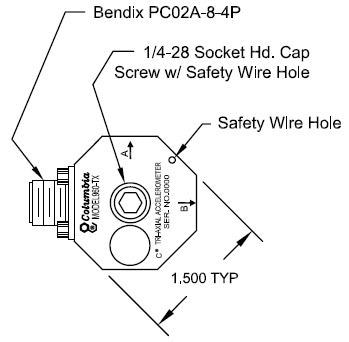

Image Credit: Columbia Research Laboratories

Specifications

Source: Columbia Research Laboratories

| Electrical |

960TX |

| Sensitivity |

10 mV/g Nominal |

| Output Impedance |

<600 Ω |

| Frequency Range @+1dB |

1 to 10,000 Hz (Single Axis)

2 to 2,000 Hz (Mounted A,B,C Axis) |

| Bias Voltage |

8±1.5 VDC |

| Transverse Sensitivity |

5% Maximum |

| Amplitude Linearity |

±1% to 100 g |

| Power Requirements |

2 mA ±5% @ a Reference of 18-30 VDC |

| Spectral Noise @ 2.5 Hz |

-116 dB/√Hz Maximum |

| Broadband |

<0.002 RMS Equivalent (2-25 kHz) |

| Absolute Phase Shift |

<6° @ 2.5 Hz Maximum |

| Relative Phase Shift |

±2° @ 2.5 Hz Maximum |

| Electrical Isolation |

Case Isolated |

| Environmental |

960TX |

| Temperature Range |

-35 to +120 °F (-37 to +48 °C) |

| Vibration Limit |

500 g Max (Sine) |

| Shock Limit |

10,000 g Max |

| Physical |

960TX |

| Finish |

Black Anodize per MIL-A-8625 |

| Size |

1.50" Hex x 0.900" H

(38.1 mm Hex x 22.86 mm H) |

| Weight |

3.17 oz (90 gm) |

| Case Material |

6061 Aluminum |

| Electrical Interface |

PC02A-8-4P |

| Case Mounting |

#1/4-28 Cap Screw |

Accessories Supplied

- Hardwood storage case

- Certificate of calibration traceable to N.I.S.T

- Standard calibration data