Efficiently monitor both established and new contaminants across various molecular categories with high sensitivity, precision, and reliability.

Traditional Airborne Molecular Contaminant (AMC) monitoring solutions often require multiple sensors to comprehensively monitor the required range of compounds. TOFWERK Semicon AMC Monitors, however, offer a single-solution approach that enables robust and simultaneous measurement of various AMC categories.

Real-Time Monitoring

Recognize and promptly respond to early-stage contamination events.

Robust Coverage

Simultaneous, ultra-fast measurements of acids, bases, condensables, and volatile organic compounds (VOCs).

Image Credit: TOFWERK

Single-Digit, Part-Per-Trillion LODs

Sensitive detection for the lowest concentrations.

Source: TOFWERK

| AMC |

CAS |

Molecule |

2s LOD (ppbv) |

1 min LOD (ppbv) |

Propylene glycol methyl

ether acetate (PGMEA) |

108-65-6 |

C6H12O3 |

0.0065 |

0.0012 |

| Propylene glycol methyl ether (PGME) |

107-98-2 |

C4H10O2 |

0.052 |

0.0094 |

| Methyl Ethyl Ketone (MEK) |

78-93-3 |

C4H8O |

0.421 |

0.075 |

| Ethyl Acetate (EA) |

141-78-6 |

C4H8O2 |

0.104 |

0.019 |

| Cyclopentane |

287-92-3 |

C5H10 |

0.132 |

0.023 |

| Acetone |

67-64-1 |

C3H6O |

0.002 |

0.0009 |

| Toluene |

108-88-3 |

C7H8 |

0.012 |

0.003 |

| Ammonia |

7664-41-7 |

NH3 |

0.408 |

0.072 |

| Hydrogen fluoride |

7664-39-3 |

HF |

0.011 |

0.0002 |

| Hydrochloric acid |

132228-87-6 |

HCl |

0.526 |

0.095 |

| Nitric acid |

7697-37-2 |

HNO3 |

0.0072 |

0.0013 |

| Chlorine |

7782-50-5 |

Cl2 |

0.001 |

0.0002 |

Comprehensive Contamination Control Throughout the Fab.

FOUP Monitoring

One of the biggest contamination risks in the fab is during the transportation of Front Opening Unified Pods from one process to the next. The sensitivity, speed, and coverage of AMC screening set a limit on FOUP cleanup.

Image Credit: TOFWERK

Facility Monitoring

Semiconductor manufacturing consists of many independent processes. Sensitive AMC monitoring is a critical component of the fab infrastructure, particularly when it comes to catching early-stage contamination events.

Image Credit: TOFWERK

Mobile Analysis

Semicon AMC Monitors are uniquely versatile and designed for easy integration across various fab settings. They enable in-situ mobile measurements for accurate AMC control and effective leak detection, particularly for sticky and reactive substances.

Image Credit: TOFWERK

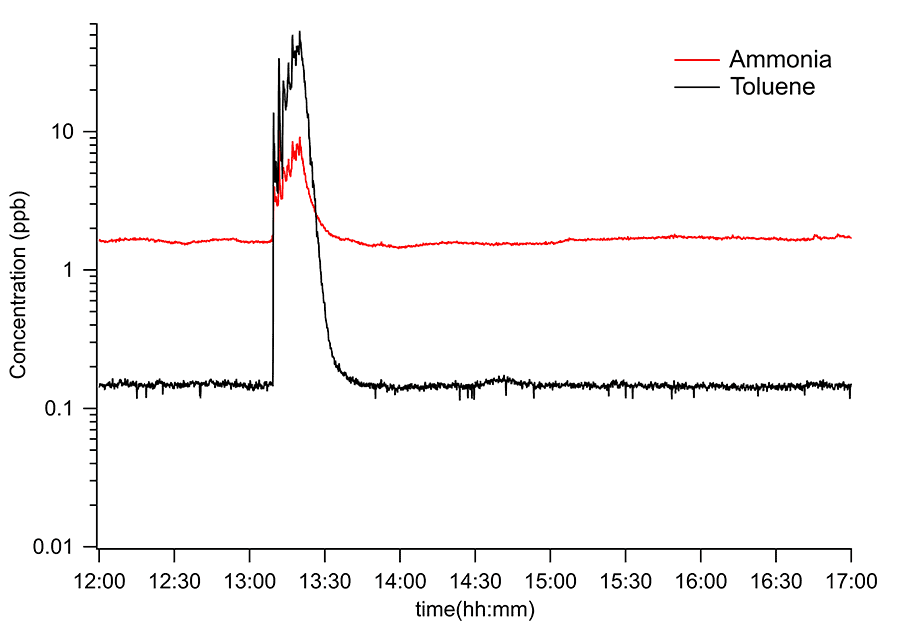

Immediate Hazard Detection

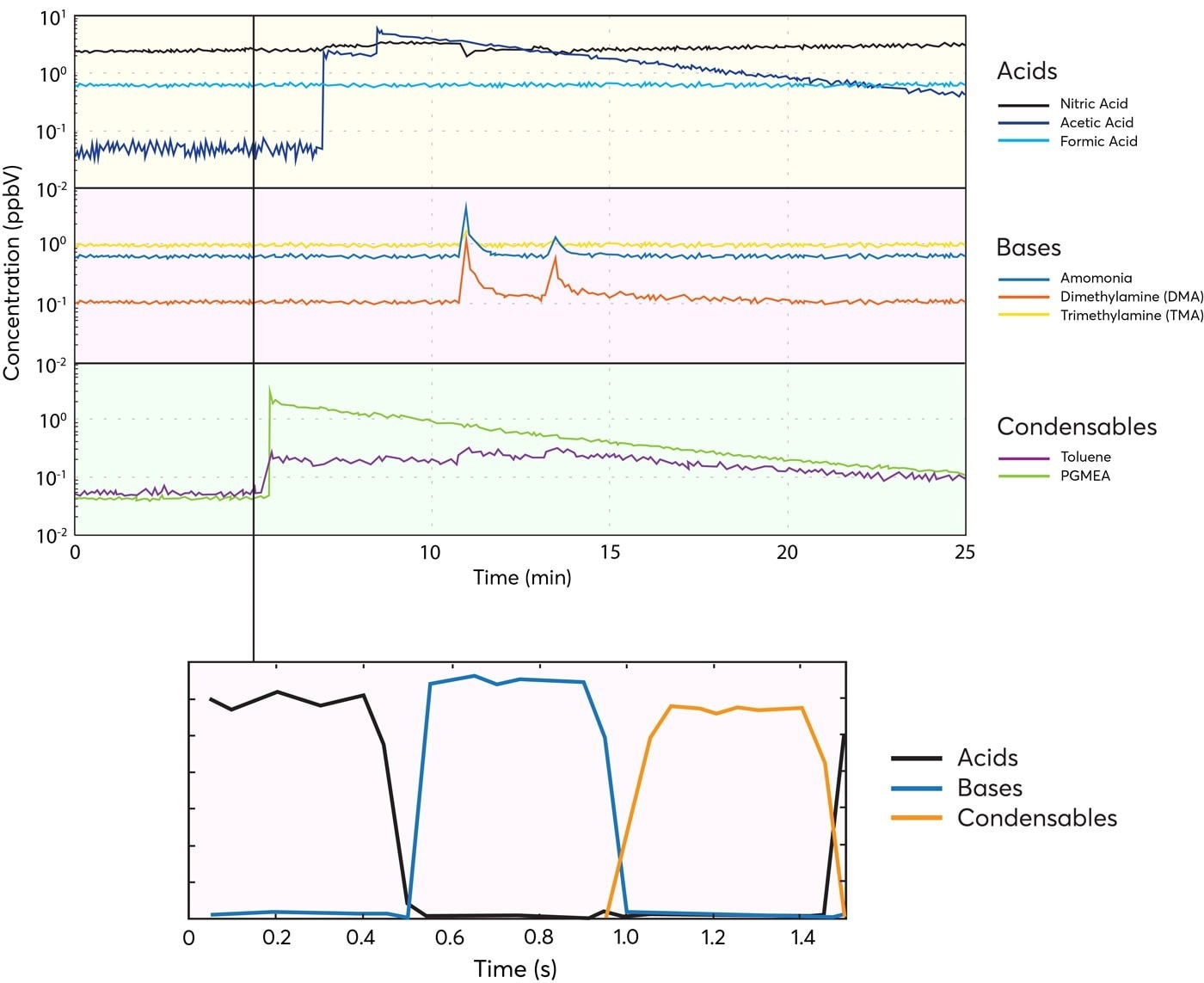

Material Off-Gassing in an ISO 5 Microtechnology Cleanroom

The material underwent a purge with Clean Dry Air (CDA) and was measured directly. Each time series shows simultaneous compound measurements with three different ionization chemistries.

Image Credit: TOFWERK

A toluene and ammonia leak was identified in an ISO 5 fine chemical cleanroom.

Image Credit: TOFWERK

Features

A full toolkit for efficient AMC management.

Real-Time Monitoring

Quickly detect and react to early-stage contamination events.

Fabs host hundreds of processes that can produce unwanted contaminants. When there is a leak or process failure, live and fast AMC reporting helps manufacturers respond quickly to and resolve contamination events.

Part-Per-Trillion Detection Limits

Extremely sensitive, ensuring that no signal is missed.

As the technology node continues to decrease, the impact trace AMCs have on production yield is amplified. Monitoring systems that do not achieve part-per-trillion detection levels are deemed insufficient when it comes to offering effective protection against contamination incidents.

Robust Coverage

Simultaneously measure Acids, Bases, Condensables, and VOCs.

AMCs are composed of a variety of molecular classes. Conventional technologies are unable to measure all relevant categories and often require a suite of instrumentation to provide adequate coverage. Semicon AMC Solutions, on the other hand, can provide comprehensive, real-time coverage for the molecular classes that pose a critical risk to semiconductor manufacturing processes.

Flexible Configurations

A solution for every application.

Semicon AMC Monitors can be specifically tailored to meet any application requirements, whether it is for monitoring fabrication process chemical leaks, assessing Front Opening Unified Pods (FOUPs) for quality control, or performing mobile facility analyses.

Customizable Target Lists

Evolves with your interests.

Monitor all critical AMCs and then continuously expand the scope to include additional ones as needed.

Retrospective Data Review

Thorough data inventory for future proof analysis.

Access to historical mass spectrum measurements is readily available. Review past incidents as new AMCs become of interest.

Specifications and Limits of Detection

TOFWERK Semicon AMC monitors are available in two versions that can be used separately or in tandem. Accessories are available for use in a variety of AMC monitoring applications.

ABC Configuration

The optimal solution for simultaneous monitoring of Acids, Bases, Condensables, and certain VOCs is provided by TOFWERK's patented fast polarity switching and Aim Reactor technology. This allows for the concurrent reporting of each compound class in the millisecond timescale, with minimal fragmentation.

ABC LODs (pptv 1 minute) for representative compounds. Source: TOFWERK

| Substance |

Formula |

LOD (pptv 1 min) |

| Hydrofluoric acid |

HF |

10 |

| Nitric acid |

HNO₃ |

5 |

| Acetic acid |

HCOOH |

10 |

| Ammonia |

NH₃ |

10 |

| Dimethylamine (DMA) |

(CH₃)₂NH |

5 |

| Propylene glycol methyl ether acetate (PGMEA) |

C6H12O3 |

5 |

| Toluene |

C7H8 |

5 |

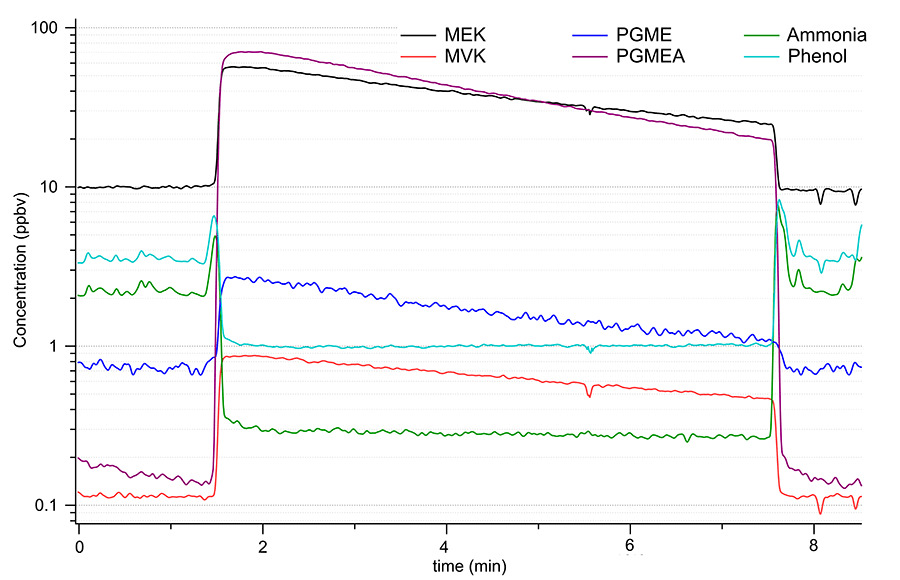

VOC Configuration

TOFWERK's VOC configuration provides comprehensive monitoring for Volatile Organic Compounds. Compared to the ABC Configuration, the VOC configuration provides more robust measurements of VOCs using PTR mass spectrometry with pptV limits of detection.

VOC LODs (pptv 1 minute) for representative compounds. Source: TOFWERK

| Substance |

Formula |

LOD (pptv 1 min) |

| Benzene |

C6H6 |

6.1 |

| Isopropyl alcohol (IPA) |

C3H8O |

9.6 |

| Propylene glycol methyl ether acetate (PGMEA) |

C6H12O3 |

13.1 |

| Ethyl acetate (EA) |

C4H8O2 |

11.4 |

| Propylene glycol methyl ether (PGME) |

C4H10O2 |

13 |

| Cyclopentane |

C5H10 |

10 |

System Specifications

Source: TOFWERK

| . |

. |

| Library |

User Defined |

| Concentration Range |

ppqv-100 ppbv |

| Resolution |

>1000 M/ΔM |

| Limits of Detection |

1-50 pptv |

| Analysis Cycle |

40 kHz |

| Mode Switching |

5 Hz |

| Operating Temperature |

10-40 °C |

| Operating Humidity |

<90% |

| Certification |

CE |

Limits of Detection

Source: TOFWERK

| AMC |

CAS |

Molecule |

2s LOD (ppbv) |

1 min LOD (ppbv) |

Propylene glycol methyl

ether acetate (PGMEA) |

108-65-6 |

C6H12O3 |

0.0065 |

0.0012 |

| Propylene glycol methyl ether (PGME) |

107-98-2 |

C4H10O2 |

0.052 |

0.0094 |

| Methyl Ethyl Ketone (MEK) |

78-93-3 |

C4H8O |

0.421 |

0.075 |

| Ethyl Acetate (EA) |

141-78-6 |

C4H8O2 |

0.104 |

0.019 |

| Cyclopentane |

287-92-3 |

C5H10 |

0.132 |

0.023 |

| Acetone |

67-64-1 |

C3H6O |

0.002 |

0.0009 |

| Toluene |

108-88-3 |

C7H8 |

0.012 |

0.003 |

| Ammonia |

7664-41-7 |

NH3 |

0.408 |

0.072 |

| Hydrogen fluoride |

7664-39-3 |

HF |

0.011 |

0.0002 |

| Hydrochloric acid |

132228-87-6 |

HCl |

0.526 |

0.095 |

| Nitric acid |

7697-37-2 |

HNO3 |

0.0072 |

0.0013 |

| Chlorine |

7782-50-5 |

Cl2 |

0.001 |

0.0002 |