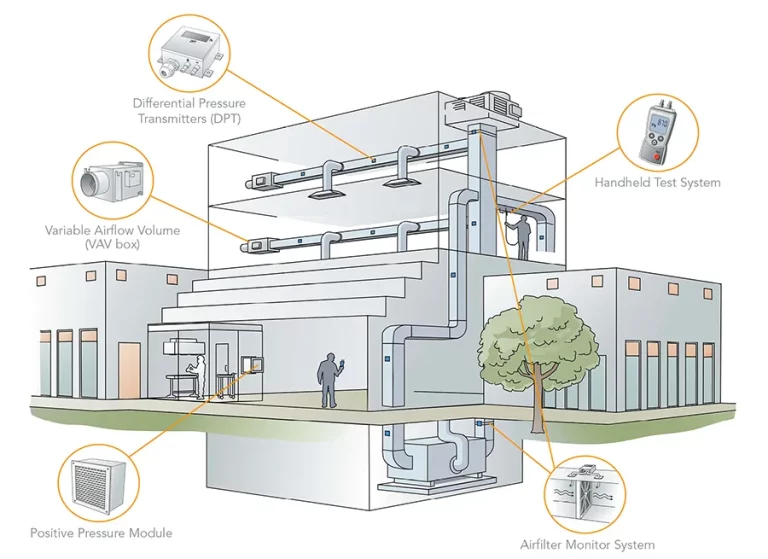

Differential pressure sensors are crucial for preserving energy and guaranteeing that HVAC systems operate to their full potential. Numerous air-handling devices and applications use sensors to measure air pressure. Here is an image of a few of the more popular ones:

Image Credit: Superior Sensor Technology

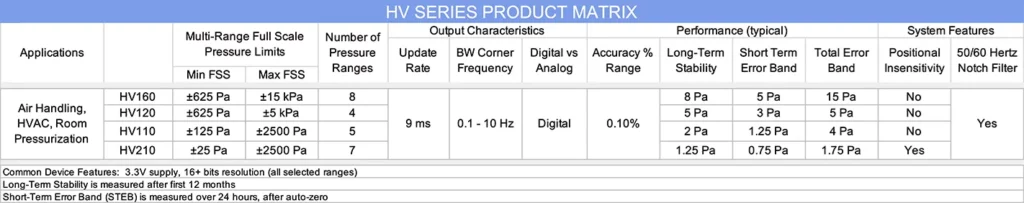

HV Series Differential Pressure Sensors

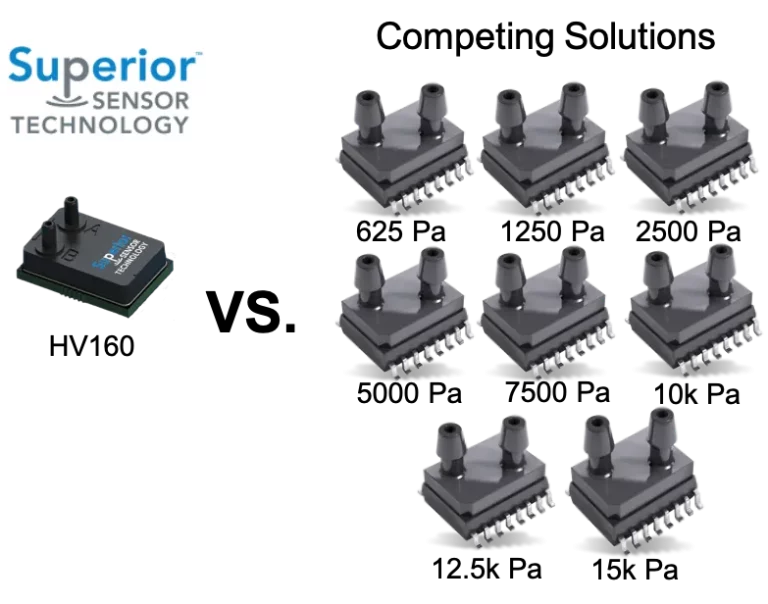

As the HV Series has a broad dynamic range, fewer sensor variants are needed to meet the rigorous functional requirements of the HVAC market. Multiple pressure ranges can be provided in a single package.

With its stable zero point and extremely low noise floor, the HV provides the highest accuracy, longest-lasting stability, and lowest error rates when measuring dry air and non-aggressive gas pressure. Starting with pressure ranges as low as 25 pascals, the exclusive Multi-Range technology allows the HV Series to support up to eight pressure ranges in a single device.

The HV Series is a great option for time-sensitive installation applications, especially because of its short warm-up period of a few minutes.

Source: Superior Sensor Technology

HV Series – Differential Pressure Sensors

Features

- Integrated Notch Filter at 50/6 0Hz

- Dual sensors that are highly integrated with ADC and DSP

- Ranges of selectable pressure are ±0.1 to ±60 in H2O

- Variable bandwidth filter with a range of 0.1 Hz to 10 Hz

- Exceptionally good accuracy ±0.1% of the chosen range

- Stability over the long run ±0.1% of FSS in the first year

- Completely integrated accounting for compensation

- Advanced digital filtering (Optional)

- Closed-loop integration (optional)

- Temperature-regulated between 0 °C and 50 °C

- Provide voltage correction

- Common SPI and I2C interfaces

Image Credit: Superior Sensor Technology

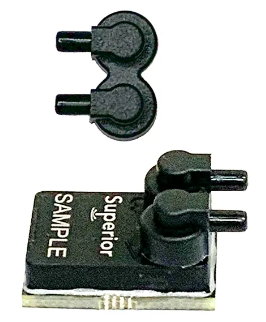

Engineering Design Resources

90° Port Adapters

Product design may require the ports facing the sides rather than the top. For a simple implementation, Superior provides incredibly dependable, premium adapters that fit into the two ports of the pressure sensors. Z-height is not an issue when using these 90° adapters.

90° adapters are available with and without o-rings:

- KP-RAR: without o-rings

- KP-ROR: with o-rings

Adapters are offered in packages of 50 and 1000.

Image Credit: Superior Sensor Technology

Recommended NimbleSense Features for HV Series

Multi-Range Technology

Up to eight distinct pressure ranges (ranging from 25 Pa (0.1" H2O) to 15 kPa (60" H2O) across the HV Series) can be accommodated by a single device. Each range is factory-calibrated and optimized to maintain constant total error band, accuracy, and stability. This reduces the intricacy and difficulties involved in utilizing several sensors. Using a Multi-Range part simplifies the design and manufacturing processes by avoiding the need to find, acquire, and integrate multiple parts.

Pressure adjustments are conveniently controlled with a single software command, and efficiency and ease of use are improved using the same component in all designs. Additionally, Multi-Range offers the convenience and added value of a single inventory item to manufacturing processes. To sum up, design and manufacturing teams recognize multi-range benefits.

Image Credit: Superior Sensor Technology

Benefits of Multi-Range Technology Include:

- Increased economies of scale by buying the same product in bigger quantities

- Adaptability in design allows for pressure range adjustments during the development cycle

- Streamlined product design by substituting one sensor for up to eight separate ones

- Reduced inventory costs for sensors and product obsolescence by up to 8 times

- The capacity to swiftly create product variations at various pressure levels without requiring modifications to the hardware design

- Lower manufacturing costs and complexity as a result of simpler sensor calibration

- Permits producers to create fewer product variations, greatly reducing the need for working capital and inventory

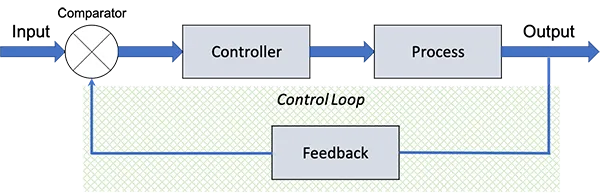

Closed Loop Control

Through pressure management, closed-loop control improves the capacity to set and maintain flow rates by directly regulating motors, valves, and actuators. Superior offers the option to incorporate this functionality into the sensor, enabling more effective flow rate control and flow rate target maintenance.

Image Credit: Superior Sensor Technology

Loop delays in electronic circuits can be significantly reduced by up to 100 times using Superior's integrated closed-loop control design. Additionally, this solution eliminates the need to create an intricate, external control loop system, resulting in more dependable, efficient, and affordable products.

It is impossible to exaggerate the advantages of integrated closed-loop control, particularly in the context of medical respiratory devices like CPAP, HVAC systems, unmanned aerial vehicles, and air quality measurement products.

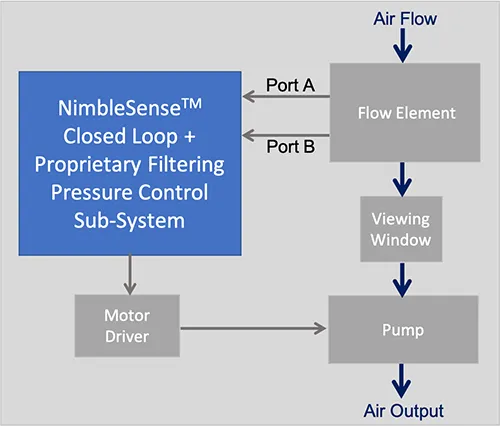

The given image shows a block layout showing the installation of an excellent closed-loop control system for an air quality application.

Image Credit: Superior Sensor Technology

Keeping the airflow through the viewing window constant and predetermined is crucial for accurate air quality measurement. The differential pressure across the venturi is a clear indicator of the flow entering the viewing window. The differential pressure sensor automatically modifies the pump drive, up or down, to maintain the targeted differential pressure and an even airflow into the viewing window by setting a target pressure level across the venturi.

Combining the company’s unique noise filtering technology with the NimbleSense closed-loop circuit successfully reduced the loop delay by over 100 times.

Benefits of the Integrated Closed-Loop Control include:

- Reduce loop delays significantly to increase the product’s accuracy and responsiveness. Eliminate discrete parts to increase the product’s dependability.

- Cut down on the total cost of the system.

- Cut down on system heat and power.

- Reduce complexity in the product design and expedite time to market

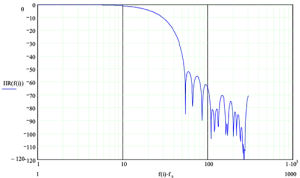

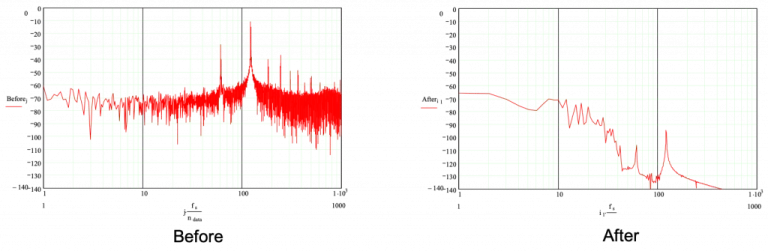

Advanced Digital Filtering

The state-of-the-art digital filter from Superior is a multi-order filter that uses sophisticated filtering techniques at the front end of the sub-system to eliminate critical noise before it reaches the pressure-sensing sub-system. Blowers, fans, and other dry air/gas sources cause this noise. This is achieved by removing sensor-induced mechanical noise before it becomes an error signal that could impair system performance overall, using NimbleSense's advanced filtering capability.

By substituting a competing component in customer deployments, the sensor has produced a more than 10-fold reduction in sensor-induced noise, significantly increasing the SNR of the sensor output. This improvement is even more notable in systems operating at extremely low pressure.

This feature significantly improves noise reduction and eliminates the need to design an external filtering system, resulting in more effective, dependable, and affordable products. It does this by incorporating both standard and optional digital filters.

Sophisticated digital filtering is adjusted to perfection for every application, guaranteeing that noise from mixed sampling is well below the noise floor. By eliminating the mechanical noise, the system's overall performance is optimized.

Here is an illustration of a 4th-order FIR filter created especially to remove pump noise above 50 Hz or a noise level equal to the signal under observation. The graphs display the results of Superior's sophisticated digital filter.

Image Credit: Superior Sensor Technology

Benefits of the Advanced Digital Filtering Technology Include:

- Significantly decreased system noise levels—by a factor of ten or more—which is crucial in applications with extremely low pressure. An improvement of 100× to 1000× is not unusual for noisy systems.

- Before noise from fans and blowers reaches the pressure-sensing sub-system, eliminate their source.

- Make product design simpler by using an integrated strategy.

- Reduce time to market by avoiding the need to create an external filtering system's design.

50/60 Hz Notch Filter

Superior’s pressure sensors possess an exceptionally low noise floor, enabling the detection of power line interference during measurements. On the other hand, this noise is effectively eliminated by the integrated 50 Hz/60 Hz notch filter. Users can continue to benefit from utilizing a pressure sensor with an extremely low noise floor without any outside interference. Furthermore, the interference brought about by these frequencies prevents the user's application from entering using the notch filter's smooth integration into the sensor module. Engineers spare the trouble of designing and implementing an external notch filter because the notch filter is already integrated into the sensor module.

Benefits of the Integrated 50/60 Hz Notch Filter include:

- Prevent noise from entering the sensing element by removing it from the power grid and AC devices.

- Make product design simpler by using an integrated strategy.

- Reduce time to market by eliminating the need to create and/or deploy an external notch filter.

- Reduced system costs overall because an external notch filter is no longer necessary.

Pressure Switch

When a predetermined pressure threshold or set point is reached, a mechanical or electronic device known as a pressure switch is triggered. These failsafe response parts give the system instructions on what to do if a predetermined pressure threshold is reached.

Types of pressure switches

Fixed Pressure Switches

As the name suggests, fixed pressure switches have pressure thresholds that the pressure switch manufacturer predetermined and cannot be changed. The pressure switch is delivered to the device manufacturer already configured, so it cannot be changed. Fixed pressure switches are frequently found in various medical devices, including ventilators.

Variable Pressure Switches

The threshold value of variable pressure switches can be set dynamically in the field or by the device manufacturer. If the device manufacturer controls it, they choose specific resistor pairs that regulate the voltage input that establishes the threshold during product construction. The threshold value cannot be altered after the product is built.

When the threshold can be set in the field, it is usually adjusted via software or a mechanical knob/switch. The pressure switch is typically not used as a safety measure in this situation. An excellent illustration of this is with air filters, where the threshold value must be changed based on the system implementation to consider any head loss in the flow stream.

Whether the measured pressure is above or below a predetermined threshold causes Superior's pressure switch to change states. This can give additional straightforward on/off system feedback and serve as a quick response failsafe feature for overpressure situations. The Superior Sensor pressure switch, in contrast to other, more widely used pressure switches, has three modes—one fixed and two variable—for determining the threshold pressure:

Fixed mode: Superior Sensor Technology establishes the threshold and gives the device manufacturer the configured, "ready for use" sensor (which includes an integrated pressure switch).

Variable mode 1: The device manufacturer can configure and set the appropriate thresholds at the time of product manufacturing.

Variable mode 2: Software allows for the field programming of pressure thresholds, allowing the pressure switch to be "tuned" based on the specific use case after the product is manufactured.

Benefits of Superior’s Integrated Pressure Switch include:

- Flexibility in three different operating modes

- Reduced system costs because there is no longer a need for an external pressure switch

- Reduced total PCB footprint

- Reduce the number of external components in the product to increase its dependability.

- Cut down on system heat and power.

- Reduce complexity in product design

- Expedite time to market