Medical ventilators are advanced mechanical systems that assist patients who cannot breathe independently by moving breathable air in and out of their lungs. These days, air pressure and flow parameters are closely managed by electronically controlled embedded processing systems to suit the needs of specific patients.

These systems are regarded as vital because they have the potential to seriously injure patients in the event of a malfunction. Because of this, the design of these mechanical ventilators is meticulous to guarantee that single points of failure do not harm patients.

The ventilation sector produces the most reliable items on the market, with suitable features and reasonable prices. It has been demonstrated that identifying and replacing sensors before they fail improves system dependability and reduces the frequency of system alarms, thus saving lives.

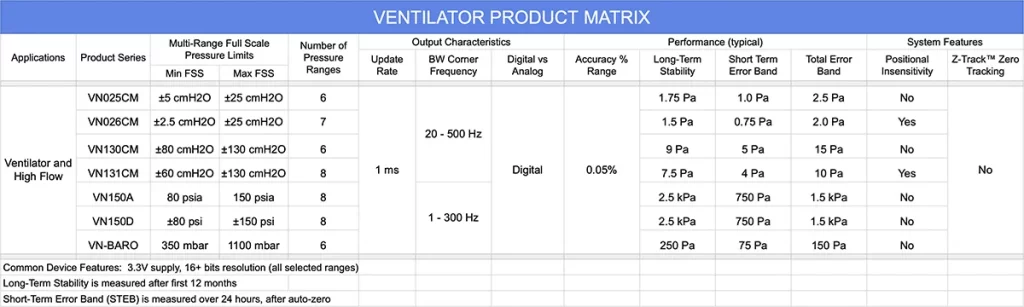

VN Series Family of Pressure Sensors

The VN Series offers a complete range of pressure sensors for high-flow oxygen devices and ventilators. The product family includes sensors for detecting inlet (wall and tank), flow, inspiratory, expiratory, and barometer pressures.

Using Multi-RangeTM technology, the series produces the broadest dynamic range in the industry without extra calibration or fine-tuning.

- Since the sensor oversamples at 12 kHz and has inbuilt bandwidth filters to produce a clean >1 kHz data rate, the ventilator does not need to oversample sensor outputs.

- Maximum precision and performance because of the very low noise floor of the architecture.

- Pure oxygen (O2) compatible.

- The VN Series is a pressure-sensing sub-system, not just a pressure sensor, thanks to its 3-mode pressure switch and optional advanced digital filtering customization.

Source: Superior Sensor Technology

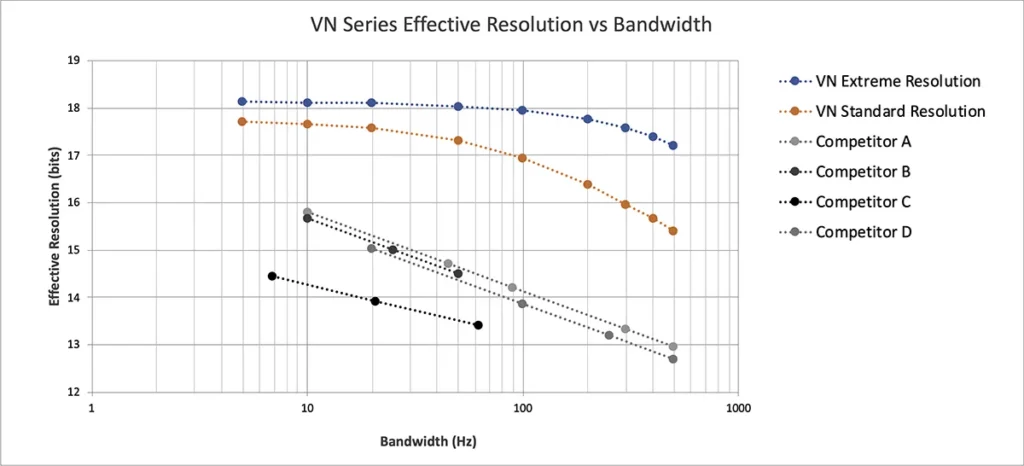

New Extreme Resolution Sensors

Superior Sensor Technology is pushing the limits of resolution with the release of the VN Series. It provides two extreme-resolution sensors with an effective resolution of about 18 bits at high bandwidth, and the product family offers an output resolution of 24 bits. This is much higher than any other pressure sensor, and the difference is noticeable in vital high-speed applications such as ventilators.

The chart below displays the measured effective resolution of the VN extreme and standard resolution components, together with various high-volume parts from rival manufacturers. The VN portions accommodate a greater bandwidth, and the effective resolution gap widens as the application's bandwidth (speed) requirements increase.

The graph illustrates that the extreme-resolution VN sensors have a 16-fold lower noise floor at 200 Hz bandwidth than the top-performing competing parts. The noise floor gap increases by at least a factor of 17 at 500 Hz. The VN Series sensors have a wider dynamic range than rival components.

Image Credit: Superior Sensor Technology

VN Series – Advanced Pressure Sensors for Ventilators

Image Credit: Superior Sensor Technology

Family of Sensors for Ventilators and High Flow Oxygen Devices

Image Credit: Superior Sensor Technology

Devices with two checks are better suited for that application versus those with one check

Features

- Sensors for flow, intake, expiratory, and barometric pressure

- Highly integrated sensor that includes DSP and ADC

- The maximum output data rate is 1.09 kHz with 24-bit resolution (for each range chosen)

- Pure O2 compatible

- Each device has up to eight selectable pressure ranges.

- Superb Zero Stability

- A Bandwidth Filter with Selectable Range of 1.0 Hz to 500 Hz

- Less than 0.15% FSS for the total error band

- Exceptionally High Precision ±0.05% of Selected Range

- Stability throughout the Long Run ±0.10% FSS

- Flow sensors with high and extreme resolution are available.

- Protective silicone gel is included with inlet and barometric sensors.

- Compensation for Temperature: 0 °C to 50 °C

- Compensation Math Completely Integrated Standard I2C and SPI Interface

Engineering Design Resources

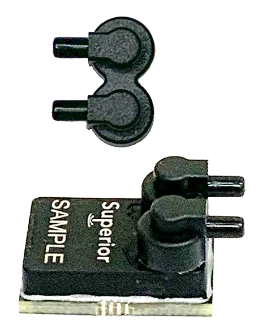

90° Port Adapters

The product design may require that the ports face the sides rather than the top. For simple installation, Superior provides incredibly dependable, premium adapters that fit into the two ports of the pressure sensors. Z-height is not an issue when using these 90° adapters.

There are 90° adapters with and without o-rings available:

- KP-RAR: o-ring-free

- KP-ROR: featuring o-rings

There are packages of 50 and 1000 adapters available.

Image Credit: Superior Sensor Technology

Recommended NimbleSense Features for VN Series

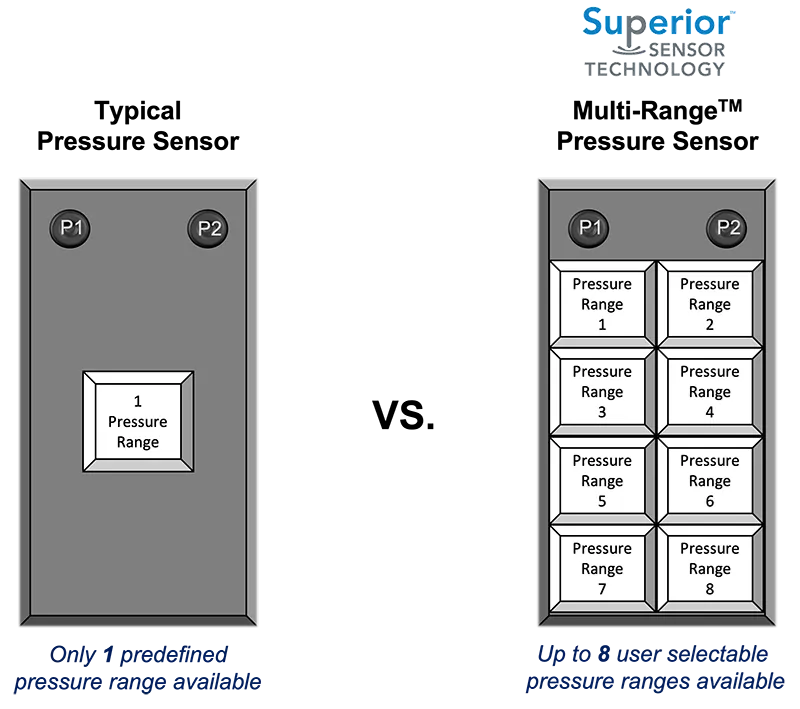

Multi-Range Technology

A single device can accommodate up to eight distinct pressure ranges; each range is factory-calibrated and tailored to maintain a constant total error band, accuracy, and stability. This reduces the intricacy and difficulties involved in utilizing several sensors.

Using a multi-range part simplifies the design and production processes by avoiding the need to find, acquire, and integrate many parts.

Pressure adjustments are readily controlled with a single software command, and efficiency and ease of use are improved using the same component in all designs. Multi-range offers manufacturing processes the simplicity and additional value of a single inventory item. Design and manufacturing teams recognize the benefits of multi-range technology.

Benefits of Multi-Range Technology Include:

- The pressure range can be adjusted with design freedom throughout the development cycle.

- Streamlined product design by replacing up to eight separate sensors with a single sensor

- The capacity to swiftly create product variations at various pressure points without modifying the hardware architecture

- Larger purchases of the same commodity to achieve more significant economies of scale

- Streamlined sensor calibration results in lower manufacturing costs and complexity.

- Reduction of sensor inventory expenses and product obsolescence by up to 8 times

- Let producers create fewer product variations, drastically reducing the working capital and inventory needed.

Image Credit: Superior Sensor Technology

Advanced Digital Filtering

Superior's state-of-the-art digital filter is multi-order and uses sophisticated filtering techniques at the front end of the subsystem to eliminate crucial noise before it reaches the pressure-sensing subsystem.

Blowers, fans, and other dry air/gas sources create this noise by removing sensor-induced mechanical noise before it generates an error signal that could impair system performance, thanks to NimbleSense's sophisticated filtering capacity.

Superior’s sensor has delivered a more than 10-fold decrease in sensor-induced noise, significantly increasing the SNR of the sensor output by substituting a competitive component in customer installations. This improvement is much more notable in systems operating at extremely low pressure.

This feature provides superior noise reduction and removes the need to develop an external filtering system, resulting in more effective, dependable, and affordable products. It does this by incorporating both standard and optional digital filters.

The sophisticated digital filtering is adjusted to perfection for every application, guaranteeing that noise from mixed sampling is well below the noise level. By eliminating mechanical noise, the system's overall performance is optimized.

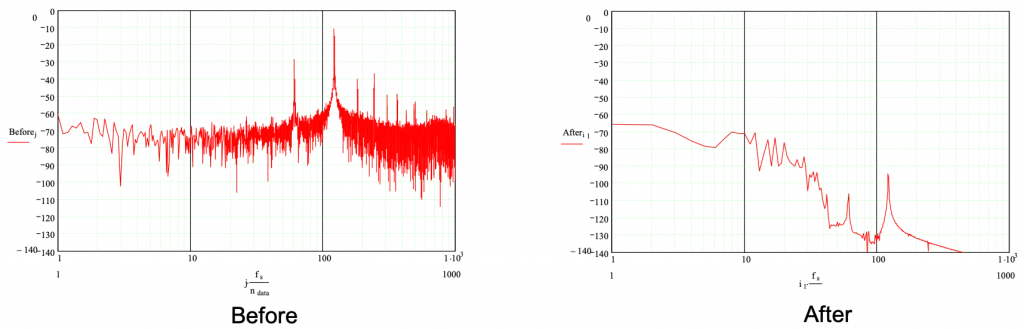

Here is an illustration of a 4th-order FIR filter created to remove pump noise above 50 Hz or a noise level equal to the signal under observation. The graphs display the results of Superior's sophisticated digital filter.

Benefits of the Advanced Digital Filtering Technology Include:

- Significantly decreased system noise levels by ten or more, crucial in applications with extremely low pressure.

- An enhancement of 100× to 1000× is not unusual for noisy systems.

- Before noise from fans and blowers reaches the pressure-sensing sub-system, eliminate its source.

- Make product design simpler by using an integrated strategy.

- Reduce time to market by avoiding the need to create an external filtering system's design.

Image Credit: Superior Sensor Technology

Pressure Switch

A mechanical or electronic mechanism known as a pressure switch is triggered when a predetermined pressure threshold or set point is achieved. If this threshold is reached, these failsafe reaction parts give the system instructions on what to do.

Types of Pressure Switches

Fixed Pressure Switches

As the name suggests, fixed pressure switches have pressure thresholds that are predetermined by the pressure switch manufacturer and cannot be changed. The pressure switch is delivered to the device manufacturer and is already configured; thus, it cannot be changed. Fixed pressure switches are frequently found in various medical devices, including ventilators.

Variable Pressure Switches

The threshold value of variable pressure switches can be set dynamically in the field or by the device manufacturer. If the device manufacturer controls it, they choose specific resistor pairs that regulate the voltage input and establish the threshold during product construction. The threshold value cannot be altered after the product is built.

If the threshold may be adjusted in the field, a mechanical knob or switch, or software is usually used to do so. The pressure switch is typically not used as a safety measure in this situation.

An excellent illustration of this is with air filters, where the threshold value must be changed based on the system implementation to account for any head loss in the flow stream.

Whether the measured pressure is above or below a predetermined threshold causes Superior's pressure switch to change states. This can be utilized to provide additional straightforward on/off system feedback and serve as a quick response failsafe function for overpressure situations.

- Fixed mode: The Superior Sensor pressure switch, on the other hand, has three options for determining threshold pressure, one fixed and the other two variable.

- Variable mode 1: The threshold is determined by Superior Sensor Technology, which also gives the device maker the configured, "ready for use" sensor with an integrated pressure switch.

- Variable mode 1: The device manufacturer can configure and specify the appropriate thresholds when the product is being manufactured.

The software allows the field programming of pressure thresholds, allowing the pressure switch to be "tuned" based on the specific use case after the device is manufactured.

Benefits of Superior’s Integrated Pressure Switch Include:

- Flexibility in three different operating modes

- Reduced system costs because there is no longer a requirement for an external pressure switch

- Reduced total PCB footprint

- Reduce the number of external components in the product to increase its dependability.

- Cut down on system heat and power

- Reduce complexity in the product design and expedite time to market

Self Aware

Ventilators are in such great demand that they must keep operating continuously. It is imperative to fix errors before they cause system alarms. Superior's exclusive Self Aware technology, when used in close partnership with partners, provides a capability that guarantees maximum uptime and total reliability.

Error-level variations are tracked using self-aware sensor technology. The technology decreases false positives in terms of error notifications and removes a single point of failure service disruption by being a component of a redundant system. Self aware can reduce pressure sensor-related alarm rates by up to 1000x.