Dec 13 2007

Two core technologies developed at the Department of Energy's Pacific Northwest National Laboratory - a fuel desulfurization system and a fuel reforming system - were instrumental in the demonstration of an electric power system operating on JP-8, a fuel commonly used in military operations.

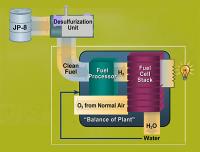

The process of converting JP-8 into hydrogen for use in the on-board fuel cell.

The process of converting JP-8 into hydrogen for use in the on-board fuel cell.

Portable fuel cell power units are quieter, more efficient and have lower emissions than standard diesel generators, but are challenged when used with JP-8 fuel because of its sulfur content. The fuel desulfurization and reforming systems developed at PNNL reduce the sulfur content of JP-8 and generate a hydrogen stream compatible with an integrated fuel cell.

"Running a noisy, hot generator in a war zone is inefficient and can give away your position," said Dale King, project manager at PNNL. "Not running it can leave you without power for communications and other critical systems."

Although currently under development for military use, the desulfurization and reforming technologies can be used with different liquid fuels to provide portable power almost anywhere that small size and high performance are important. Researchers at PNNL are also extending the desulfurization technology for use with diesel fuel.

The fuel cell-centric auxiliary power unit is modular and can be reconfigured for a wide range of uses. Researchers envision the technology being used to supply auxiliary power and heat for long-haul commercial trucks, which would replace the need to run less efficient internal combustion engines while the vehicle is stopped. Battelle, which operates PNNL for DOE, operated a prototype system demonstrating these technologies during the three-day 2007 Fuel Cell Seminar this fall. During the demonstration, an integrated 5-kilowatt electric power system successfully powered area lights and a commercial refrigerator.

A unique catalytic hydrodesulfurization process developed by PNNL removes sulfur from the JP-8 fuel using syngas as the co-reactant in place of hydrogen. Gas phase operation of the process allows for a significant increase in throughput and decrease in operating pressure compared with conventional technology. The process doesn't require consumables or periodic regeneration. The system was developed with funding from the U.S. Army Tank Automotive Research, Development and Engineering Center.

Fuel cells combine hydrogen and oxygen to produce electrical energy with water and heat as by-products. The process is clean, quiet and highly efficient - potentially up to three times more efficient than internal combustion engines. Envisioned benefits include reduced emissions, increased reliability, multi-fuel capability, durability and ease of maintenance.