Abresist Corporation, a Kalenborn Company, introduces 2 new KERAFLEX wear protection systems, consisting of ALRESIST® high alumina ceramics or KALMETALL®W hard overlay welding plates vulcanized to a steel base. These systems are well suited where high abrasion and impact occur in combination. Maximum operating temperature is 176º F / 80º C.

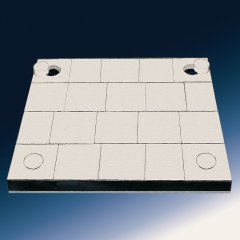

KERAFLEX reduces noise and is especially well suited for use in transfer chutes in belt conveyor systems and impact zones in bunkers and silos. These wear protection systems are produced in standard panels, up to 20” square, with welded studs or countersunk bolting attachments.

KERAFLEX-KRM consists of ALRESIST® high alumina ceramics with a tile thickness of ½” or 1”. The thickness of the rubber is determined by the severity of the impact. KERAFLEX-WRM consists of KALMETALL-W hard overlay welded plates, rubber and steel. KERAFLEX-KR, with 1/8” to 1/2” thick ALRESIST® tile and a rubber backing only, provides for a flexible lining that is glued in place.

Abresist Corporation will be attending the Electric Power show in Booth No. 921 from May 12-14, 2009 in Rosemont, IL.