Given the same size of machine, the co-rotating twin-screw extruders of the ZSK MEGAcompounder and ZSK MEGAcompounder PLUS series have an output capacity many times greater than that of their forerunners. The decisive factors for the increase in output are the optimized screw geometry (Do : Di = 1.55, where 'Do' is the outer diameter and 'Di' the inner diameter of the screw), the increase in available torque at the screw shafts (specific torque Md / a³ = 13,6 Nm/cm3, where 'a' is the centre-to-centre distance between the screws) and the resulting possible increase in screw speed to 1,200 r.p.m. and over.

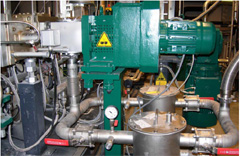

The ZS-EG 70 twin-screw side venting unit, shown here mounted on a ZSK

MEGAcompounder PLUS, is distinguished by its high venting capacity and reliability in

operation; it can simply be swung to one side for maintenance and cleaning purposes.

Photo: Coperion, Stuttgart/Germany.

The ZS-EG 70 twin-screw side venting unit, shown here mounted on a ZSK

MEGAcompounder PLUS, is distinguished by its high venting capacity and reliability in

operation; it can simply be swung to one side for maintenance and cleaning purposes.

Photo: Coperion, Stuttgart/Germany.

By reason of its enormous processing competence and expertise – as Dr. Peter Heidemeyer explained at the Coperion Open House in Stuttgart/Germany in January 2009 – Coperion is able to combine this performance increase with other innovative measures in order to achieve high outputs in a great many different processes while at the same time maintaining, or even increasing, reliability in operation. Moreover, Coperion ensures, not least through its wellcoordinated material and process technology, that machine wear is reduced to a minimum and product quality is optimized in spite of the extremely high energies that have to be converted mechanically.

Innovative solutions for feeding and venting zones

Among the most important innovative measures are the improvements in the feeding zone and the installation of a twin-screw side venting unit. In processes with feed limitations, e.g. when processing products of low bulk density and hence high air and moisture content, the feed capacity can be considerably increased with the aid of so-called Feed Enhancement Technology (FET). With this technology, the feeding zone is provided with a porous, gaspermeable wall, to the exterior of which a vacuum is applied, enabling the feeding zone to take in a much larger volume of material and hence also contributing to an improvement in the melting process in the downstream section of the extruder, as the volume of gas entrained by the material into this section is considerably reduced. The geometry of the screw in the feeding zone has also been optimized. Especially when processing products with such feed limitations as those described above, and without waiving any reliability of operation whatsoever, these two measures together can double or triple the volume of material fed into the extruder! FET can be used not only on the twin-screw extruder itself but also, and with the same feedenhancing effect, on the ZS-B twin-screw side-feeder systems. Thus it is possible to feed lowdensity products into the compounding extruder downstream of the feeding zone and at a high rate of feed. Typical FET applications are, for example, the production of highly talc-filled or chalk-filled compounds, the filling of polypropylene with microscopic hollow glass beads, the compounding of wood-polymer composites (WPC) or the production of masterbatch.

The new ZS-EG twin-screw side venting unit fully matches the high capacity of the MEGAcompounder PLUS. Its twin screws hold back the melt in the compounding extruder and enable the gas to vent in the opposite direction to their conveying direction. The unit's high venting capacity is made possible by its deep-flighted screws, while the relatively low speed of the vented gas ensures that hardly any product residues are entrained out of the extruder by the gas. Any residual product that does find its way out of the extruder is separated from the gas stream before it can enter the vacuum pump. Thanks to its side mounting position, the ZS-EG is user-friendly; it can be swung to one side for full and easy access to its interior. Its typical applications are, for example, the production of glass fibre reinforced or highly filled compounds, wood-polymer composites (WPC) or thermoplastic elastomers (TPE).

The importance of materials for wear resistance

The available materials for the barrel and the screw elements differ considerably not only in terms of abrasion and corrosion resistance but also in respect of cost. Naturally, an optimum choice of materials is not possible without precise knowledge of the intended application. Using the HIP process (Hot Isostatic Pressing), for example, the barrel can be rendered abrasion and corrosion resistant by providing its basic ductile/malleable steel body with a wear-resistant coating having a hardness of 60 to 65 HRC. In the case of screw elements, particularly good results can be obtained with a protective layer produced with the aid of CVD technology (chemical vapour deposition) on a highly wear-resistant powered-metallurgical sintered steel.

Aids to making product development fast and transparent

A newly introduced quick-release coupling for small compounders (ZSK 18 to 34) permits very fast screw change. It shortens the cleaning times, for example, when changing over from one product or colour to another, thus enabling the user to make better use of available capacity.

The coupling has male and female connectors – similar to those of a garden hose coupling – and is very easy to use.

Complementing the above-described new developments are newly introduced aids for the development of new plastic products.

- Sampling plate for speeding up product development: The plate enables the user to take a specimen from the extruder barrel in less than 10 seconds, even if the extruder barrel is only partially filled. It is available for use with ZSKs with screw diameters ranging from 18 to 92 mm.

- See-through barrel plug quite literally makes product development transparent. It permits the user to observe the process in the extruder barrel. It will withstand temperatures of up to 250 °C, has a large observation window and can be used on ZSK sizes up to 40/43.