Mar 8 2009

Until now, sample analysis of unknown bulk material alloys or unidentified coatings has required certain knowledge of what to expect before accurate quantitative results could be obtained.

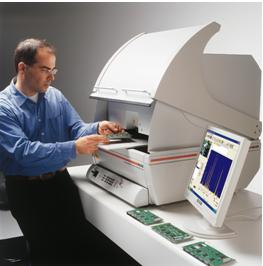

A modern coating thickness and analysis X-ray system

A modern coating thickness and analysis X-ray system

A new X-Ray technique developed by the Helmut Fischer Institute pre-empts this need and has far ranging applications from lead soldering issues affecting the electronics industry and aerospace and military, through to practicalities on the plating shop floor, where plating shop operators can quickly make accurate coating thickness measurements without selecting specific programmes.

The key to this advanced analysis software lie in automatic ‘Class Determination', whereby groups of specific applications are stored in a library and when a sample is presented to the instrument, this library is scanned an the application with the closest fit selected. This saves operator time, negates the need for a skilled operative and removes any possible operator errors.

From the article by Dr. Volker Rossiger Chief Physicist of the Helmut Fischer Institute. To read the full article, visit www.fischer-material-analysis.co.uk