Jul 30 2009

Crystal Technology Inc. (CTI), market leader in the growth and production of lithium niobate wafers and 100 percent subsidiary of EPCOS, has launched PPLN (periodically poled lithium niobate) chips for the generation of green laser light from a conventional semiconductor laser source. Thanks to CTI's high technological competence ranging from crystal growth to mass production, EPCOS is the only company able to manufacture PPLN chips in the quantities required for high-volume green laser applications.

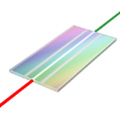

While compact semiconductor laser sources for red and blue light are already available, there are none that are capable of directly emitting green light. With the new PPLN chips it is now possible to convert the near infrared wavelength of a single-mode laser at 1060 nm to a green laser at 530 nm.

First commercial design of miniature projectors for full-color high-resolution images enabled

Thus, the new chips, which measure as little as 1 x 0.5 x 1 mm³, enable for the first time the commercial design of ultra-compact projectors capable of displaying a full-color high-resolution image. The PPLN chips can be used in applications such as miniature projectors in mobile phones, notebook computers or other compact mobile devices, head-up displays in vehicles, micro-displays in headsets, or displays in retail stores.

Using the process of periodical poling CTI inverts the polarization of the lithium niobate wafer into a series of alternating crystal domains that measure approximately 3.5 µm throughout the wafer thickness of 0.5 mm. The PPLN material is doped with magnesium oxide in order to make the material capable of withstanding high light intensities. MgO:PPLN chips are available both with and without dielectric anti-reflection coating.

The product range of the new PPLN chips from EPCOS comprises three lengths, 1 mm, 3 mm and 10 mm, to support both short and long pulsed sources at various power levels. Custom designs are also available.