Shrinking the size of processor chips implies accommodating millions of transistors in a confined space. Although these chips enable faster computers, they come with a shortcoming of generating multiple hot spots. This article discusses a solution to combat such limitations.

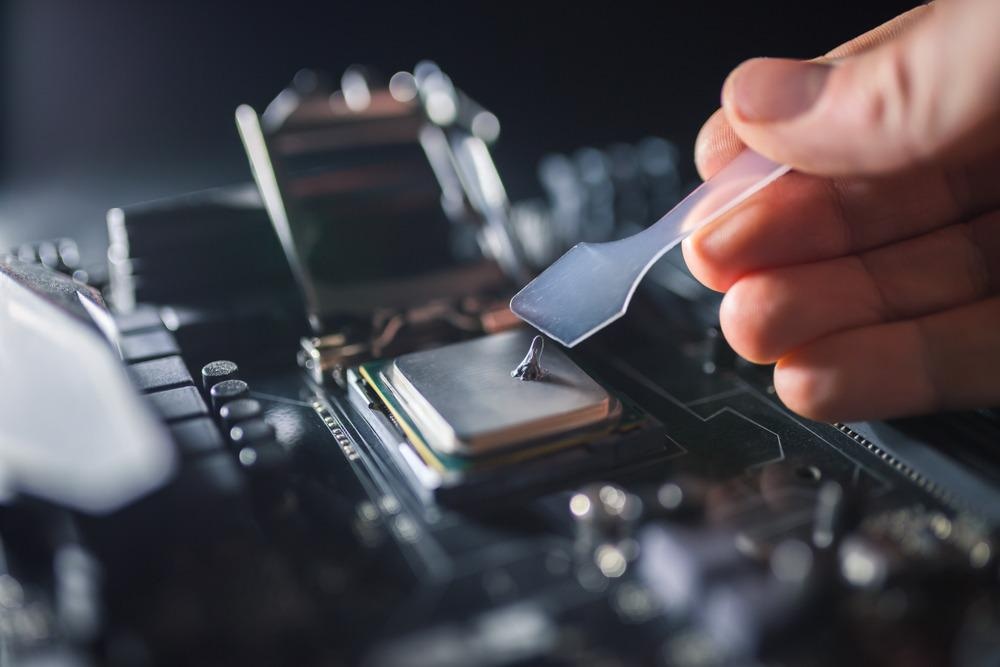

Image Credit: Petr Svoboda/Shutterstock.com

Thermal Interference Material (TIM)

TIM is used in electronic devices that generate heat and raise the device’s temperature. TIM aids in good performance of the devices, low power consumption, and reduces internal damage. An ideal TIM has a low coefficient of thermal expansion (CTE). Additionally, this material should possess a soft texture for easy deformation between the mating surfaces.

What is Thermal Paste?

Thermal paste is a TIM applied between a processor and heat sink to enable heat dissipation. Like other TIMs, thermal paste has high thermal conductivity and low thermal expansion. Its application to the processor chip prior to installing a cooling solution to fill in any air gaps helps in facile heat dissipation.

Need for Thermal Paste in Processors

Developing high-power electronic devices with their simultaneous miniaturization is of critical importance. Consequently, the compactness in computers calls for higher integration of transistors inside processor chips for a computer's faster operation.

However, long-time use of these devices releases excessive heat. If not removed quickly and effectively, this excess heat may decrease the life span of the electronic device. Hence the enhancement of heat dissipation is of critical importance in processor chips.

The metal-based central processing unit (CPU) and its integrated heat spreader (IHS) appear to have a smooth surface to the naked eye yet are filled with micro-sized air gaps. Given that air is an insulator, these air gaps in the CPU and IHS result in heat traps leading to inefficient heat dissipation into heatsinks. On the other hand, the application of a thermal paste realizes the goal of heat dissipation through heat conduction from the processor to the IHS.

Composition of Thermal Paste

Thermal paste, also known as thermal grease, is commonly made of silicone-based polymers. Properties such as low viscosity and high thermal conductivity of sodium-silicate-based thermal paste make it superior to its silicone-based counterpart. Some disadvantages of silicone-based thermal pastes are their sloppiness and difficulty in removal by dissolution.

On the other hand, polyethylene glycol-based fluidic pastes containing thermally conductive particles can efficiently fill the gaps in the materials in contact. Thus, it is common to use materials with a high thermal conductivity as fillers in thermal pastes. The thermal conductivity of thermal paste increases with filler content to a certain extent, beyond which the conductivity decreases due to an increase in viscosity.

Using carbon nanotubes (CNTs) as a TIM in electronic devices has gained considerable attention recently due to its anisotropic high thermal conductivity of individual nanotubes. Moreover, theoretical calculations revealed that the thermal conductivity for single- and multi-wall carbon nanotubes were 6000 Wm-1K-1 and 3000 Wm-1K-1, respectively. A homogenous mixture of CNTs with various polymer types serves as TIMs.

Recent Studies on Nanomaterials-Based Thermal Paste

In a recent study published in the International Journal of Engineering Science Invention, the authors used TIM in the form of thermal paste to determine thermal contact resistance. They used copper nanoparticles as thermally conductive filler material in tricosane paraffin wax and commercially available carbon nanotube paste as base fluid. The results showed that copper nanoparticles mixed with CNT at 20 wt.% showed a low thermal contact resistance of 0.27 ° C/W.

In another study reported in the International Conference on Manufacturing Technologies, the authors prepared thermal grease by mixing copper nano-powder in silicone oil by the electric line explosion method. The results showed that the thermal conductance increased with the addition of copper nano-powder up to 15vol.%, beyond which the thermal conductance showed a decreasing trend due to high viscosity.

Another study published in the journal Nanomaterials used a reduced graphene oxide-hexagonal boron nitride (RGO-hBN) as filler in the silicone-based thermal grease. They reported that RGO-hBN/silicone thermal grease with lower viscosity exhibited higher thermal conductivity and lower thermal resistance. Its thermal management capability was better than hBN/silicone thermal grease with the same filler content.

Conclusion

A major challenge in designing processor chips is managing the heat influx through its dissipation into heat sinks. Moreover, it is necessary to fill the air gaps on the metal surfaces in contact to avoid heat traps. To this end, a thermal paste containing thermally conductive materials as fillers in a polymer base fills these air gaps and has good thermal conductance to dissipate the heat quickly and effectively from the processor to the heat sink.

More from AZoM: The Use of NDT in Archaeological Analysis

References and Further Reading

Mai PT, Bui TA, Van Tran H, Van Pham T, Nguyen DN, Phan MN, Bui TH. Application of Graphene Silicone Grease in heat dissipation for the Intel Core i5 Processor. JOIV: International Journal on Informatics Visualization, Volume 3, 2019, Pages 222-226. http://joiv.org/index.php/joiv/article/view/260

Maheshwari SU, Pillai BC, Govindan K, Raja M, Raja A, Pravin MB, Kumar SV. Development of Low Resistance Thermal Interface Material TIM Using Nanomaterials. 2017, Pages 39-46. http://www.ijesi.org/papers/ICAFM-2017/Volume-1/6.%2039-46.pdf

Hashim NH, Anithambigai P, Mutharasu D. Thermal characterization of high-power LED with ceramic particles filled thermal paste for effective heat dissipation. Microelectronics Reliability. 2015, Volume 55, Issue 2, Pages 383-388. https://www.sciencedirect.com/science/article/pii/S002627141400451X?via%3Dihub

Kang, H, Kim, H, Park, S, Yang, J, and Huh, S. A Study on the Thermal Properties of Thermal Grease with Copper Nanopowders. In IOP Conference Series: Materials Science and Engineering, 2020, Volume 842. https://www.researchgate.net/publication/342214716_A_Study_on_the_Thermal_Properties_of_Thermal_Grease_with_Copper_Nanopowders

Liang W., Ge X., Ge J., Li T., Zhao T., Chen X., and Liu R. Three-dimensional heterostructured reduced graphene oxide-hexagonal boron nitride-stacking material for silicone thermal grease with enhanced thermally conductive properties. Nanomaterials. 2019, Volume 9, Issue 7, 938. https://pubmed.ncbi.nlm.nih.gov/31261720/

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.