At the IC MOVPE XV in Lake Tahoe (23-28 May) many outstanding talks dealt with process optimization by means of optical in-situ metrology. One of them was presented by Mr. Veit Hoffmann of the Ferdinand Braun Institute Berlin (FBH).

For the growth control of GaN based laser diodes, the team at FBH uses LayTec's brand new Pyro 400 for direct temperature measurements on the wafer surface and EpiCurve TT to control wafer bowing and pocket temperature.

Temperature

measurements at FBH:

the pocket temperature

measured by Epi-

Curve TT at 950 nm (red

curve); GaN surface

temperature measured

by Pyro 400 (orange curve).

Temperature

measurements at FBH:

the pocket temperature

measured by Epi-

Curve TT at 950 nm (red

curve); GaN surface

temperature measured

by Pyro 400 (orange curve).

Mr. Hoffmann investigated the influence of different substrate materials (sapphire and GaN) and different growth conditions on the wafer bow and the temperature uniformity during growth of the laser's active region.

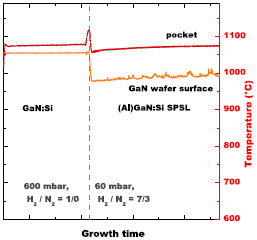

Fig. 1 shows an example of temperature measurements at FBH during AlGaN buffer growth on GaN. After changing the pressure from 600 mbar to 60 mbar and H2 to 70%H2/30%N2, the temperature dropped. The EpiCurve TT, which measures the 950 pyro emission, showed that the pocket temperature (red curve) decreased insignificantly, whereas the GaN surface temperature measured by Pyro 400 dropped by 75 K (orange curve). This difference could not have been detected without Pyro 400.

The study proved that the wafer surface temperature is affected by changes of pressure and gas phase much stronger than the pocket temperature. This is because the modified thermal conductivity and the thermal capacity of the gases at low reactor pressure results in an increased vertical temperature gradient between pocket and ceiling.

Mr. Hoffmann of FBH commented: „With Pyro 400 we obtain valuable information about temperature effects that are not visible to the conventional infrared pyrometers. Today, this is the best method to improve the uniformity of the surface temperature." Using a convex pre-bowed GaN substrate and changing the growth conditions, the active region could be deposited on nearly flat wafers with homogeneous temperature distribution.