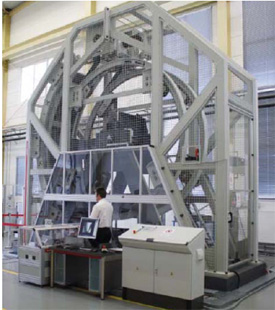

The success story of Zwick pendulum impact testers continues in 2010. The China Petroleum Materials Corporation in Xi'an has placed an order with Zwick for what will be the largest pendulum impact tester ever built. With a height of more than 6.5 meters and total weight of more than 90 tonnes (pendulum including base), it will be used for testing pipe materials for pipelines according to ASTM standard E436 and API standard RP5L3.

Zwick is setting a new benchmark with the largest pendulum impact tester in the world - the pendulum hammer alone is 2.1 meters long and weighs two tonnes. Technical support and flexibility in implementation were decisive factors in the design and development of this unique project.

Pendulum impact tester HIT 50kP for impact tests up to 50,000 Joule

Pendulum impact tester HIT 50kP for impact tests up to 50,000 Joule

The enormous size of this pendulum impact tester created particular challenges for safety technology. For example, an intelligent retainer protects the user from the swinging pendulum, and a hydraulic brake ensures that it stops completely and safely returns to its starting position after the test. Furthermore, safety dictates that material samples can only be placed in the machine outside of the testing room. The specimens are placed in the pendulum automatically and the pendulum can then be activated from any angle required.

Tests can be carried out in temperatures as low as -70°C (-94°F).