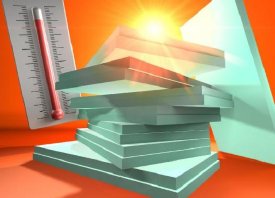

BASF has now extended its range of extruded polystyrene rigid foam panels (XPS) with an innovative product. The new insulation material is called Styrodur HT (HT = high temperature). Its key feature is a heat distortion temperature of up to 105° Celsius (application limit temperature).

This makes the foam suitable for all applications exposed to high temperatures and requiring the proven properties of Styrodur C: high compressive strength, low water absorption, resistance to rot and outstanding insulation performance. Like all of BASF's Styrodur C panels, the insulation panels can be recognized by their green color. Conventional XPS can be used at a temperature of up to 75°C.

Styrodur HT stays dimensionally stable even with high ambient temperatures and with high solar radiation. BASF offers the new insulation material at nominal compressive strengths of 300 and 600 kPa. Styrodur HT is particularly suitable for inverted flat roofs subject to heavy loads, for insulating hot water tanks (including those in contact with the ground), for various insulation applications in solar technology and for all special insulation applications with hot water which are exposed to pressure and moisture. Thus, the service life of these applications is considerably increased.

Insulation material Styrodur C

The pressure-resistant, water-repellent, and rot-proof Styrodur C has been protecting houses from heat, cold and moisture for over 40 years, increasing the life of buildings, enhancing their value and improving the room climate. The various Styrodur C grades, which all contain only air as cell gas, differ mainly in their compressive strength.