Feb 9 2011

Duro-Last® Roofing, Inc. is adding a new fleeceback roofing system to its product offerings.

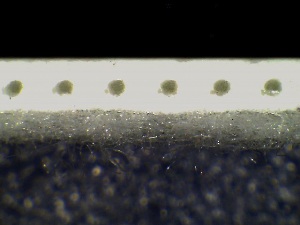

The Duro-Last Fleeceback™ System combines Duro-Last’s proven thermoplastic membrane and high-quality, five-and-a-half ounce fleece material that’s bound to the underside of the membrane during manufacturing.

Cross Section of Duro-Last Fleeceback System

Cross Section of Duro-Last Fleeceback System

The fleece offers enhanced adhesion characteristics between the membrane and the substrate underneath. In addition to standard fully-adhered installations, the Duro-Last Fleeceback System can be used for direct-to-deck applications, non-nailable-deck applications, and projects where a specific aesthetic look is desired.

For some applications, it can also act as a separation barrier, which may reduce project material costs and speed up installations that otherwise would require an additional separator sheet. The Duro-Last Fleeceback System can be applied using Duro-Last’s water-based WBII adhesive or a new two-part bead-applied Fleeceback adhesive. Duro-Last is one of the few manufacturers in the roofing industry to offer the Fleeceback adhesive. According to Steve Ruth, Duro-Last’s Vice President of Sales and Marketing, the Duro-Last Fleeceback System provides another option for contractors, architects, and building owners who need an adhered roof installation.

“This product is ideal for several situations, such as where the installation requires a smooth, finished appearance, or where the membrane needs to be applied to concrete, lightweight concrete, or gypsum decks. Some areas, particularly the southern United States and Gulf Coast, are fast-growing markets for fleece installations.”

The Duro-Last Fleeceback membrane is available in 50- and 60-mil thicknesses, and will be sold to contractors in full rolls only: 50-mil – 5 feet x 100 feet and 10 feet X 100 feet: 60-mil – 5 feet x 80 feet and 10 feet x 80 feet.