Scientists at the Rutgers School of Engineering have discovered a new class of highly robust metal alloys that could prove ideal for producing compact and highly responsive switches, sensors and springs.

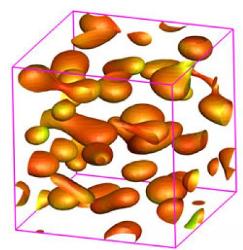

Decomposed two-phase nanostructured alloys

Decomposed two-phase nanostructured alloys

A professor of Materials Science and Engineering in the Rutgers School of Engineering, Armen Khachaturyan and postdoctoral scientist, Weifeng Rao are analyzing the new metal alloys. According to them, the alloys can be utilized in powerful loudspeakers, ultra-sensitive microphones, springier blood vessel stents and parts that enhance the performance of clean-burning diesel and gasoline engines, security systems and medical imaging devices.

The materials that the researchers are analyzing are scientifically called as ‘decomposed two-phase nanostructured alloys’. The alloys are produced by cooling metals that were treated to high temperatures so that one crystal structure of the nano-sized particles is entrenched into another kind of structure. The structure thus produced allows the metal to deform when stress is applied and regain shape when the stress is removed. This unique property called as ‘non-hysteresis’ makes the nanostructured alloys better than conventional metals in the production of magnetorestrictive and piezoelectric parts.

Conventional metals need energy input to regain their initial shapes, while the new metal alloys eliminate this requirement and thus enhance energy efficiency. The new materials may demonstrate larger or smaller shape modifications and yield force depending on a variety of magnetic, electrical and mechanical input and material processing.