A new chemical reactor called spinning disc reactor has been developed by Marco Meeuwse, a researcher at Eindhoven University of Technology (TU/e). The reactor is ideal for fine chemical and pharmaceutical industry applications.

The higher mass transfer rate of the spinning disc reactor enhances the efficiency and safety of chemical manufacturing processes that involve liquids, solids and gases.

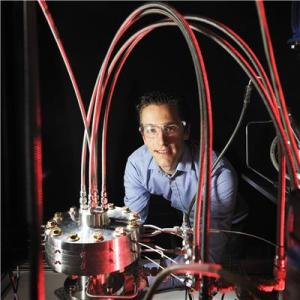

Eindhoven University researcher Marco Meeuwse with one of his test systems for the rotor-stator spinning disc reactor.

Eindhoven University researcher Marco Meeuwse with one of his test systems for the rotor-stator spinning disc reactor.

The earlier work of Dr.ir, John van der Schaaf, assistant professor and co-supervisor of Meeuwse, led to the development of the reactor. The professor believed that when the rotating disc is joined with a close wall, fast turbulence and high shear stress can be created and this could result in high efficiency. Meeuwse was requested to study the feasibility of this theory. After four years of study, the spinning disc reactor became a reality and its performance was found to be better than conventional reactors.

Through the cylinder base, gas is supplied to the spinning disc reactor. The gas bubbles produced inside the reactor are removed by the rotating liquid’s flow. Hence, when the rotational speed is high, the bubbles will be small and the surface area will be large. This results in a greater reaction rate and mass transfer. The outcome has been confirmed by examining the measurements of mass transfer and the images of gas-liquid flow.

In addition, the new chemical reactor is safe to use as it is too small compared to conventional reactors. This is a major benefit in chemical processes that use harmful materials.

The reactor is being further developed at TU/e. A leading equipment producer and other pharmaceutical and chemical companies are involved in the project.