Congratulation to Rony Moreno the winner of Taylor Hobson's World Record competition. Rony completed the measurement of 5 precision bearings, in tolerance including loading and setup in 77.77 seconds.

Rony Moreno finished top of the leader board with a staggering 77.77 seconds a time well worth the ipod competition prize, Rony like other competitors had a brief product overview before his attempt. 5 others registered times of less than 100 seconds.

Rony commented: "I was impressed with the accuracy, especially considering the instrument was on an exhibition booth" And "The instrument is very fast and easy to use with its touch screen interface".

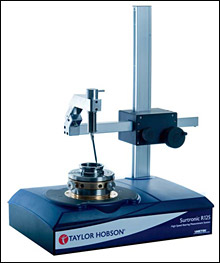

Surtronic R-series

A range of roundness products robust enough for shop floor but accurate enough for any inspection room.

Working closely with manufacturers across a wide range of industries including precision bearings, automotive and aerospace engineering Taylor Hobson have focused on the key attributes that are most important for quality control in today's precision industries

The new Surtronic R100/R105 of instruments offer a flexible solution for all your roundness and form requirements with a variety of systems and application specific accessories and fixtures that can be tailored to your specific need.

The most important benefit these systems offer is speed. In precision industries as manufacturing volumes increase all too often the bottleneck is metrology. High measurement throughput systems ensures higher sampling rates can be achieved while supporting increased manufacturing volumes.

Although many times faster than traditional benchtop roundness systems there is no loss of precision or accuracy. Full ISO compliant measurements can be taken with +/-25 nm spindle accuracy and 6nm gauge resolution (30nm for R100/R105)

All systems are designed for constant 24 hour, 7 days a week use in demanding shop floor environments; manufactured using only the most durable and hard wearing materials.

The X-sight touch screen software platform with intuitive navigation make the Surtronic roundness system as easy to use as a SatNav with everything you need at your fingertips.

World's highest throughput roundness system…

- Increase manufacturing output

- Ensure part traceability

- Reduce part scrappage

- Improve 'right first time'