Hitachi Metals, a manufacturer of materials and components, has developed new metal interconnect materials that have greater strength and oxidation resistance. These materials are designed for applications in solid oxide fuel cells (SOFC).

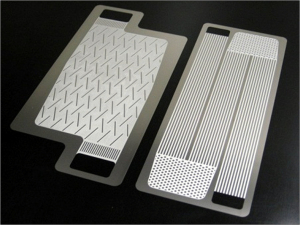

Interconnect Processing (Etching)

Interconnect Processing (Etching)

Interconnects are critical parts used to electrically link individual fuel cells. The major features required in interconnect materials are coefficient of thermal expansion with the value being close to zirconia ceramics electrolytes, good electrical conductivity and reliable oxidation resistance at specific operating temperatures ranging from 700°C to 850°C.

Inadequate oxidation resistance often occurs with the use of general stainless steel such as 430ss. But nickel-based alloys like Alloy 600 have exceptional oxidation resistance and high coefficient of thermal expansion. Similarly, aluminum-based alloys possess excellent oxidation resistance, but they do not have sufficient electrical conductivity.

In order to meet the required features, Hitachi Metals has taken intense efforts to develop advanced interconnect materials. The company has developed ZMG 232G10 and ZMG 232J3 interconnect materials that enhance strength, oxidation resistance and electrical conductivity, surpassing the levels attained in ZMG 232L, a ferritic stainless steel.