Leo Bendersky, who serves as materials scientist at the National Institute of Standards and Technology, believes that iron-veined magnesium could be utilized to fabricate the fuel tank for hydrogen-fueled vehicles.

Iron-doped magnesium powder grains store more hydrogen.

Iron-doped magnesium powder grains store more hydrogen.

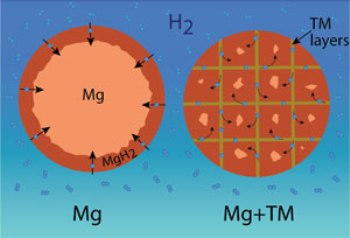

Iron-doped magnesium-based powder grains can quickly absorb and release adequate amounts of hydrogen, making them suitable for the safe storage of hydrogen fuel. These powder grains need 60 s for saturation with hydrogen at a relatively low pressure and temperature of 150° C, which are critical factors for safety in commercial vehicles, Bendersky said.

An ideal material would need to store a minimum 6% of its own weight in hydrogen gas and could securely be charged with hydrogen within the same duration needed to fill gasoline in a car. The NIST researchers developed an infrared light-based device to study the after effects of evaporation of magnesium and its coupling with small amounts of other metals to create fine-scale mixtures.

The researchers observed that iron created capillary-like channels inside the grains, forming paths for hydrogen transfer inside the metal grains that enable hydrogen to be rapidly absorbed inside. Bendersky stated that the iron-doped magnesium-based powder grains could store as high as 7% of hydrogen by weight.

Bendersky further said that the new measurement technology can disclose effectively about the process of absorption of hydrogen by a material than by the standard X-ray diffraction method, which is restricted to studying the averaged properties of a material.