Researchers at the Karlsruhe Institute of Technology have come up with a new method to fill the electrodes that are present in lithium ion batteries. Electrodes in batteries are filled with pores measuring the size of a micrometer.

KIT

KIT

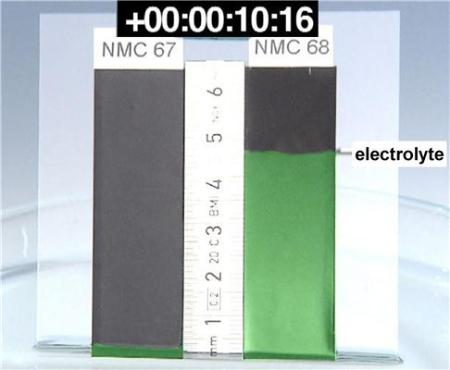

This results in the electrodes occupying a large area on the surface and the occurrence of chemical processes that create an electrical charge and discharge. This entire process is particularly useful for large electrical vehicles that have to cover long distances. However, for the batteries to work at their maximum efficiency, the electrodes have to be filled up entirely.

The liquid electrolyte acts as a medium of transport enabling the charged ions to flow between anodes and cathodes and the charge is equalised and there is flow of current outside. However, the materials that are traditionally used in electrodes and electrolytes offer bad-wetting of the surface of the electrode by the liquid electrolyte. At present, time consuming processes are used to fill the pores of the electrodes forcibly. KIT researchers however, have used a mechanico-chemical process to modify the electrodes in such a manner that they absorb the liquid electrolyte, ensuring that the liquid is spread into all the pores consistently. This results in an increased performance in the batteries. This procedure also reduces the time and the expense involved in filling the electrodes. The patent for this method has been applied and efforts are being taken to acquire licensing for the same. Many major companies have approached KIT to obtain the licensing contract for this method, which has the potential to reduce the cost of batteries.