Increased consumer demand for more memory storage has led to recent advances in the semiconductor industry and semiconductor manufacturers are now investing heavily in the next generation 450mm wafers.

Pilot lines are being built worldwide and key to their success is the ability to produce chips in an efficient and economical way. Ceramic semiconductor wafer handlers from Morgan Advanced Materials will be a critical component, enabling manufacturers to improve productivity and yield.

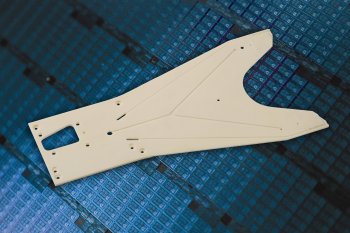

Ceramic Semiconductor Wafer Carriers from Morgan Technical Ceramics.

Ceramic Semiconductor Wafer Carriers from Morgan Technical Ceramics.

The company is at the forefront of product development for the demanding environments of semiconductor processing and its applications engineers work closely with chip manufacturers to develop ceramic end effectors capable of handling large diameter wafers. Morgan Advanced Materials' end effectors are proven to work reliably with 300mm wafers, enabling semiconductor manufacturers to optimise their processes, and they are set to be the component of choice for handling 450mm wafers.

This is because ceramic features excellent mechanical and chemical properties capable of withstanding the harsh and corrosive environments found in the etching process. It has exceptional structural strength and stiffness compared to alternative materials such as aluminium. As a result, larger, thinner wafer handlers can be made, which allows wafers to be stacked closer together for greater productivity. For example, the company's 99.5% alumina is a strong material that will support the heavier, larger diameter wafers and is only one millimetre at its thinnest part.

Also, ceramic does not bend like an aluminium equivalent. If forced, the alumina ceramic will break, thereby offering the advantage of minimising potential damage caused to the semiconductor equipment and enabling straightforward replacement.

"Until now there has been much debate as to when 450mm wafers will become a reality because of the heavy upfront investment in research and development required," says Yannick Galais, commercial manager at Morgan Advanced Materials. "However, it is now clear that they are expected to come online in 2015 and our ceramic end effectors are expected to be key components to enable efficient wafer processing."

Morgan Advanced Materials' has been supplying reliable wafer handlers to the semiconductor industry for more than 10 years. Its products are installed in fabrication plants all over the world helping semiconductor manufacturers to optimise their processes, maximise yields and reduce their total cost of ownership.

The company also designs and manufactures a wide range of equipment, including ceramic-metal brazed assemblies, CMP pad conditioners, sputtering targets and ion beam systems. Its experts are involved at many stages of the manufacturing process to assist with development, prototype and production needs.